Latest Leak Tester

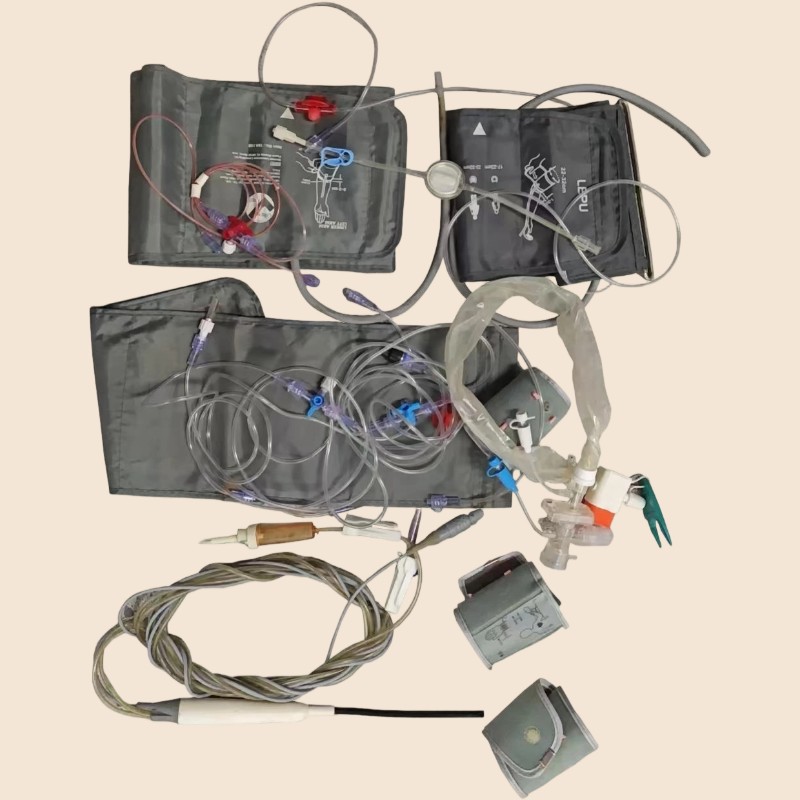

High-precision sealing performance testing equipment, providing reliable leak testing solutions for hardware, electronics, security lighting, and other industries

Actual price depends on product customization

Product Overview

- Latest Leak Tester is a multifunctional and customizable leak testing system that supports multiple testing methods to meet the inspection requirements of different industries.

- Custom fixtures can be flexibly configured according to the structure of the tested product. It is widely used in e-cigarette e-liquid tanks, consumer electronics, automotive components, medical devices, new energy batteries, and precision hardware.

- The system is equipped with an industrial-grade touchscreen interface. Parameter setup is intuitive and convenient, supporting real-time data display, automatic judgment, and result traceability, significantly improving testing efficiency and consistency.

Quality Assurance

Our products ensure testing quality and user experience through multiple core features

Suitable for Multiple Scenarios

75° Adjustable Viewing Angle

Higher Accuracy

High Sensitivity

Stable & Interference-Resistant

Customized Solutions

Product Details

Operating System & UI Pages

Pressure Setting Page

Instrument UI Interface

Testing Technologies & Methods

Test Configuration

Includes air source processing unit, pressure regulation module, and precision sensors, forming a complete closed-loop testing system.

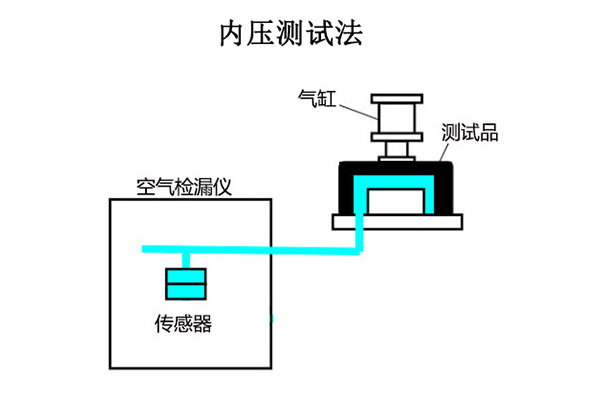

Internal Pressure Test Method

By filling the tested part with a specific pressure of gas and monitoring pressure changes to evaluate sealing performance, suitable for closed-chamber testing.

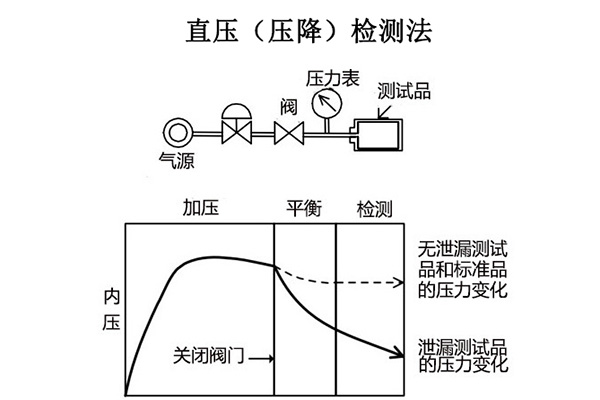

Direct Pressure (Pressure Decay) Test Method

Directly applies test pressure and monitors pressure decay, ideal for production environments requiring high testing speed.

Core Advantages

High-Precision Testing

Equipped with imported high-precision pressure sensors (accuracy ±0.1% F.S) and a 24-bit AD acquisition chip. Detection sensitivity reaches 0.1 Pa, ensuring accurate and reliable results.

High Testing Efficiency

Optimized pressurization and testing workflow combined with fast-response sensor systems enables a single product test cycle to be shortened to under 1 second, significantly improving productivity.

Flexible Testing Modes

Supports both positive and negative pressure testing methods. Multiple built-in test programs allow customized parameter settings based on product characteristics to meet diverse testing needs.

WAFU

WAFU