Sealing Inspection for Home Appliances

The airtightness testers provided by WAFU Brothers play a crucial role in the home appliance industry, ensuring product sealing, durability, and water resistance. Leveraging advanced airtightness testing for home appliances, our systems accurately inspect sealing performance and effectively detect gas leaks and air leakage. Whether it's pressure leak testing or micro-leak detection, our solutions enable efficient quality control. Through non-destructive testing and automated leak testing systems, we enhance testing efficiency and ensure product reliability in the appliance sector.

Portable Electric Cleaning Brush

Prevent Water Ingress: Used in bathrooms, kitchens, washbasins, and other humid environments, sometimes even in direct contact with water. Once moisture or liquid enters the interior, it can easily cause motor or PCB short circuits, leading to safety hazards.

Enhance User Confidence: Portable electric cleaning brushes on the market are usually labeled with a waterproof rating. Leak testing is a critical prerequisite for achieving and verifying the claimed waterproof level.

Production Quality Control: By adopting leak testing, sealing defects can be identified during the inspection stage, reducing after-sales costs.

Adapt to Product Characteristics: Portable electric cleaning brushes typically have multiple potential leak points. Leak testing enables quantitative inspection of the entire product or key areas, ensuring reliable sealing performance after assembly.

Robot Vacuum Water Tank

Protect internal electronic components: If sealing issues cause water leakage, moisture may damage the internal circuitry, motor, or main control system of the robot vacuum.

Ensure stable water control: Insufficient sealing of the water tank may lead to unstable water pressure, uneven water output, or failure of water control, affecting mopping performance.

Identify manufacturing defects: During plastic injection molding, microscopic pores or fine cracks may form inside the water tank, which are often difficult to detect through visual inspection.

Prevent secondary contamination: Water leakage may cause dirty water to seep into the dust box or roller brush, leading to bacterial growth and unpleasant odors.

Juicer Housing

Moisture challenges: Kitchen appliances often operate in humid and splash-prone environments, requiring protection against liquid ingress.

Safety risks: Liquid entering the motor or control compartment may cause short circuits, electric leakage, or damage.

Certification requirements: Failure to meet IPX4–IPX7 waterproof ratings may hinder market launch or export.

Transportation risk: Pressure changes during shipping may cause liquid leakage, leading to package contamination and increased return rates.

Steamer Inner Pot

Sealing Challenge: The steamer inner pot operates in high-temperature and humid environments, and poor sealing can easily cause leakage.

Safety Risk: Air or water leakage in the inner pot may lead to uneven heating, or even electrical failures and safety hazards.

Quality Standards: Steamer inner pots that fail airtightness and pressure resistance testing cannot meet factory inspection and certification requirements.

Transportation Risk: During long-distance transportation, changes in air pressure and temperature may cause leakage of the inner pot, increasing return rates.

Sweeping Machine Water Control Component

Functional Requirement: Controls the water outlet and stop-water operation of the sweeping machine. Poor sealing performance will affect user experience.

Safety Risk: Unqualified airtightness can cause water leakage, easily leading to electrical malfunctions and safety hazards.

Quality Standard: As a water control component, it inevitably comes into contact with water during use. If airtightness does not meet standards, it cannot pass factory inspection or certification requirements.

After-sales Risk: Water leakage can impair even the basic sweeping function, increasing the rate of complaints and product returns.

Robotic Vacuum Plastic Float Ball

Performance Requirement: If the float ball takes in water or leaks air, the internal air volume changes, causing reduced buoyancy and inaccurate water level sensing, which leads to incorrect water level judgment.

Potential Risk: If the float ball’s airtightness is insufficient, water may seep inside, causing water level detection failure. This can result in continuous water flow or leakage, posing electrical safety hazards.

Quality Control Requirement: A leaking float ball may become a weak point in the overall waterproof system, affecting the robotic vacuum’s overall IP waterproof rating.

User Experience Impact: If water leakage causes inaccurate water level detection, the robotic vacuum’s mopping function may malfunction, severely affecting the user experience.

Plastic Coupling for Robot Vacuum Cleaners

Performance degradation: If the plastic coupling leaks, the air duct pressure will drop, causing a significant loss of suction power.

Increased noise: Air leakage disrupts airflow stability, intensifies duct vibration, and creates sharp noise that affects user comfort.

Unstable water supply to the mop: Poor sealing in water-route plastic couplings may cause leakage at the bottom and damage electronic components.

Outgoing quality must be controlled: The coupling is small and structurally complex. Molding tolerances and ultrasonic welding deviations can affect sealing performance.

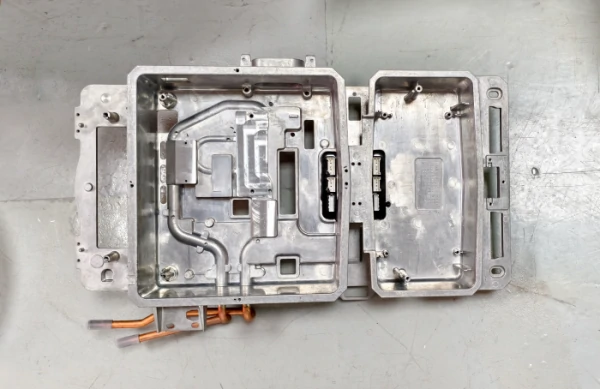

AC Die-Cast Parts

Prevent air or moisture intrusion: Poor sealing may allow moisture or impurities in the air to enter the system, which could freeze at low temperatures and block pipes.

Maintain system pressure: Refrigeration systems need to operate at a specific pressure, and leaks can disrupt pressure balance.

Prevent long-term risks: Minor leaks may not affect initial use, but over time they can worsen and cause premature AC failure.

Protect electrical components: AC units contain circuits and electronic components. Leaks allowing moisture to enter can cause short circuits or electrical leakage.

WAFU

WAFU