Automotive Parts Industry Testing Case

Wafu Brothers provides critical technical support in leak testing for the automotive industry. Their high-precision testing equipment is widely used in sealing tests for engines, transmissions, fuel systems, air conditioning systems, and braking systems, ensuring no leaks in core components to enhance vehicle performance and safety. The company also supports body sealing tests to improve in-cabin comfort. With advanced technology and solutions, Wafu Brothers helps automakers meet stringent environmental and safety standards, becoming an important industry partner.

Automotive Side Mirror Turn Signal

If moisture penetrates into the turn signal, it may condense on the inner surface of the lens due to temperature changes. Long-term water accumulation can lead to circuit short circuits.

Moisture or dust adhering to the reflector or LED lens can cause light scattering and reduced brightness, severely affecting the visibility of turn signals.

Installed on the exterior of the vehicle, it is exposed to high-pressure car washing, heavy rain, and day–night temperature variations during actual use.

Vehicles must meet strict quality standards before leaving the factory, including waterproof and dustproof ratings.

Automotive A/C Components

Automotive air conditioning systems rely on a sealed refrigerant circuit. Once even a minor leak occurs in a component, refrigerant will gradually escape, directly leading to reduced cooling performance.

Automotive A/C systems operate under positive or high pressure. If component sealing is inadequate, pressure instability may occur, and in severe cases, it can result in component damage or safety hazards.

In real-world use, components are subjected to complex conditions such as high and low temperature cycles, vibration, and aging. Minor sealing defects at an early stage are often amplified over long-term operation.

Once leakage occurs in automotive A/C components, it may pose potential safety risks.

New Energy Battery Case Sealing Inspection

Poor battery sealing may allow moisture or dust to enter the battery, causing insulation degradation, internal short circuits, and in severe cases, fire or explosion.

Electrolyte leakage can corrode electrodes and connectors, reducing battery capacity and charge/discharge efficiency, significantly shortening driving range.

Battery housings should meet at least IP67 standards to ensure stable operation in rain, humidity, or dusty environments.

Battery packs need to undergo pressure and vacuum testing during design and inspection to ensure no leakage under external pressure.

Motorcycle Headlight Testing

Moisture Ingress: Rain, mud, or car wash water can enter the engine bay through poorly sealed areas, causing electronic components to get damp, corrode, or short-circuit.

Headlight Performance Impact: The intake system drawing in water or dust-laden air can severely affect engine life and efficiency.

Reduced User Satisfaction: Seal defects may cause increased wind noise, heat escape, and unpleasant odors inside the cabin, impacting user experience.

Impact on Overall NVH and Protection Level: For premium vehicles, the engine cover’s sealing integrity directly affects vehicle certification levels (e.g., IP rating, NVH, thermal simulation verification).

On-Board Charger

Prevents water ingress short circuits: In rainy driving or high-pressure washing, poor sealing can cause water ingress leading to short circuits and damage.

Ensures insulation safety: Moisture intrusion can cause circuit board breakdown and failure, affecting the vehicle’s charging system.

Meets protection rating requirements: Most on-board chargers must pass leak tests to meet IP67/IP68 ratings.

Improves overall vehicle quality and reliability: Sealing issues are a key reason for high after-sales maintenance rates and customer complaints.

Engine Hood Assembly

Moisture ingress: Rainwater, dust, and wash water can enter the engine bay through poor seals, causing electronic component dampness, corrosion, and short circuits.

Engine performance degradation: Intake of water or dust-laden air seriously affects engine life and efficiency.

Reduced user satisfaction: Seal defects can increase wind noise, heat leakage, and odors inside the cabin.

Affects overall vehicle NVH and protection ratings: Especially for high-end models, the sealing integrity of the engine hood directly impacts vehicle certification (e.g., IP ratings, NVH, thermal simulation validation).

Driving Monitoring Sensor

Lens fogging and blurred images: Affect autonomous driving and assistance functions.

Water ingress causes electronic component short circuits: Module failure and system errors.

Sensor false alarms or non-responsiveness: Safety risks.

Fails to meet IP67/IP69K protection certifications: Cannot be shipped or is returned by customers.

Reverse Light

Pressure Decay Method: Inflate the light housing, then check if internal pressure decreases; low cost and fast testing speed; suitable for small, regularly shaped reverse light assemblies.

Mass Flow Method: Use mass flow sensors to detect internal leakage flow of the taillight; accurate data and high stability, supports automated testing; suitable for high-precision or LED control circuit reverse lights.

Helium Leak Detection (optional): Used in R&D or high-end vehicle testing for micro-leak detection; higher cost and generally used during validation phases.

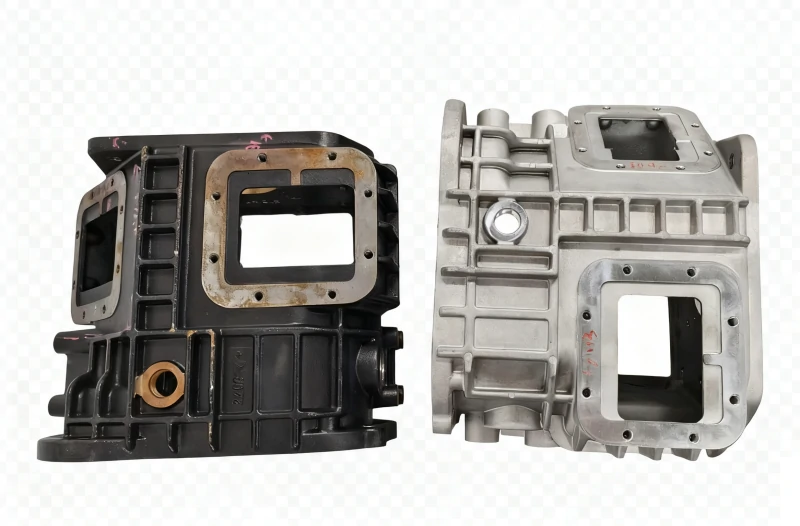

Transmission Housing

The transmission is filled with oil that lubricates gears, bearings, and other moving components. If the housing has undetected micro leaks, it can lead to overheating, component damage, or even seizing of the transmission.

When the transmission housing lacks sufficient leak, external moisture, rainwater, or car wash water may seep inside, causing the lubricant to emulsify, reducing performance, and leading to corrosion of internal gears and bearings.

As modern automotive manufacturing standards continue to rise, component precision must also improve to meet overall performance requirements. The transmission housing must therefore meet specified leak standards.

For OEMs and suppliers, neglecting leak testing may result in oil leakage issues after delivery, product recalls, increased after-sales complaints, and damage to brand reputation.

Oil Divider

Ensures the proper operation of the lubrication system. Any leakage or seepage in the oil divider can cause insufficient lubrication, increased wear, or even component failure.

The oil pressure in a lubrication system typically ranges from 0.5 to 10 bar, and even higher in high-end systems. If the divider fails to maintain airtightness at these pressures, equipment malfunction may occur.

Automotive parts manufacturing must meet strict quality control standards to ensure the oil divider’s quality meets requirements.

Ensures longer vehicle lifespan.

WAFU

WAFU