Multi-Channel Airtightness Tester

High-precision sealing performance testing equipment, providing reliable airtightness solutions for automotive, electronics, medical, and other industries

Final price depends on product customization

Product Overview

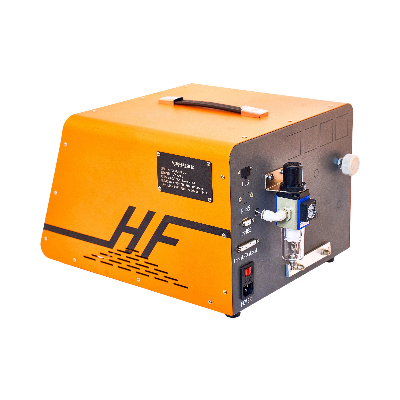

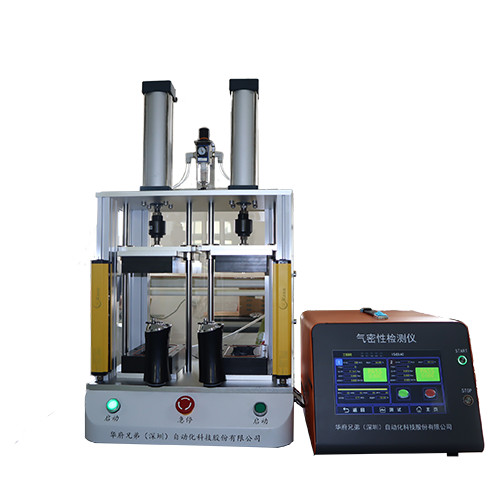

- The 6th Generation WF Multi-Channel Airtightness Tester is a flagship product crafted by Wafu Brothers after 16 years of dedicated innovation, combining high efficiency, precision, and multifunctionality.

- This device can simultaneously test airtightness and perform IPX waterproof testing on multiple products, achieving detection accuracy up to 1Pa and delivering results as fast as 3 seconds, leading the industry in performance.

- The 6th Gen WF supports custom integration of various detection methods including differential pressure, flow, and direct pressure, flexibly adapting to diverse process requirements. Its core uses high-precision sensing technology, accurately capturing even the tiniest leaks to ensure product sealing quality.

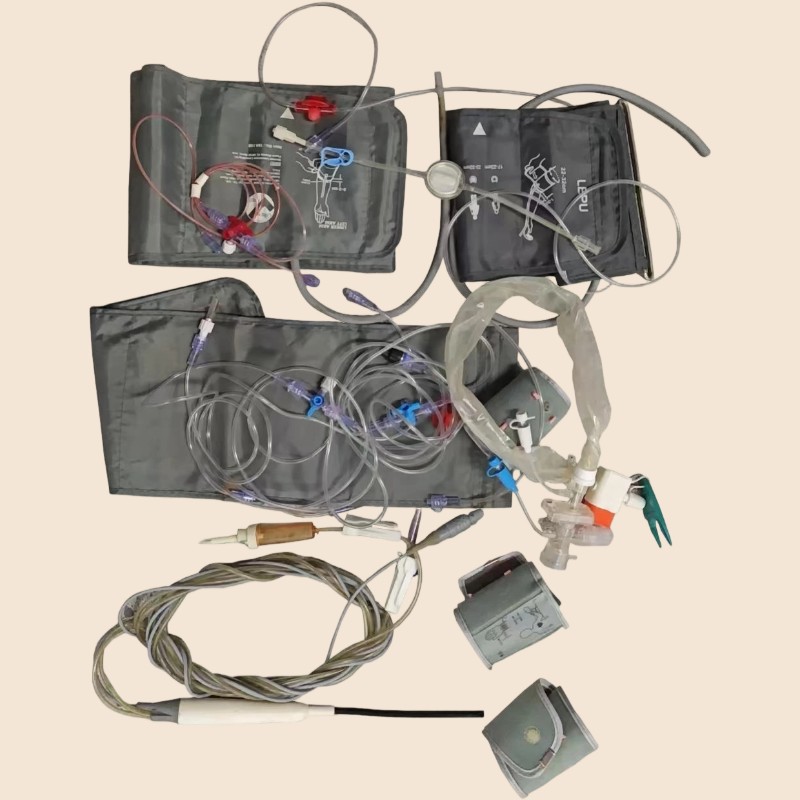

- The device covers a wide range of applications across key industries such as automotive manufacturing, aerospace, consumer electronics, medical devices, and new energy batteries — the first choice for enterprises pursuing high quality and reliability.

Quality Assurance

Our products ensure testing quality and user experience through multiple core features

Wide Applications

75° Adjustable Viewing Angle

Higher Precision

High Sensitivity

Stable and Anti-Interference

Customizable

Product Details

Appearance & Interaction Design

All-metal Body Design

Made with high-strength aluminum alloy housing, precisely machined and surface treated for strong anti-interference capability, suitable for long-term use in industrial environments.

7-inch HD Touchscreen

Simple and intuitive user interface, supports multi-language switching, equipped with auxiliary guidance, making it easier for operators to learn quickly.

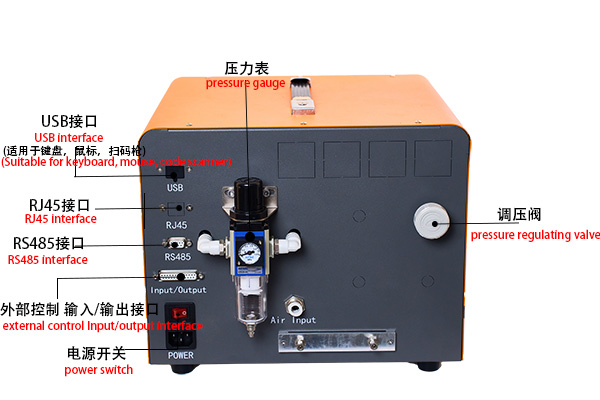

Rich Interface Configuration

Equipped with multiple communication interfaces such as RJ45, USB, and mouse ports, facilitating integration with other devices to realize automated testing processes.

Operating System & UI Pages

Pressure Setting Page

Instrument UI Interface

Testing Technology & Methods

Test Composition

Includes air source treatment unit, pressure regulation module, and precision sensors, forming a complete closed-loop detection system.

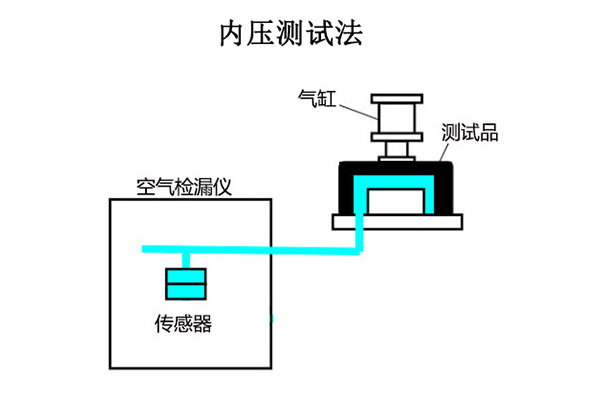

Internal Pressure Test Method

By injecting a specific pressure gas inside the test workpiece, pressure changes are monitored to determine sealing, suitable for closed cavity testing.

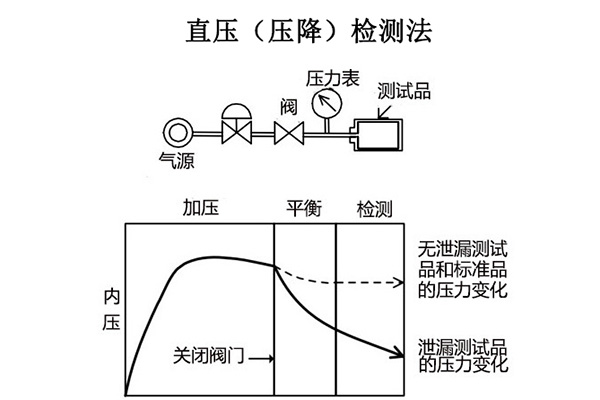

Direct Pressure (Pressure Drop) Test Method

Directly applies test pressure and monitors pressure decay, suitable for production scenarios requiring high-speed testing.

Core Advantages

High-Precision Testing

Uses imported high-precision pressure sensors (accuracy ±0.1% F.S) and 24-bit AD acquisition chips, with detection sensitivity up to 0.1 Pa, ensuring accurate and reliable test results.

High Efficiency Testing Speed

Optimized inflation and testing flow design, combined with fast-response sensing system, reduces single product testing cycle to less than 1 second, improving production efficiency.

Flexible Testing Modes

Supports both positive and negative pressure testing methods, built-in multiple testing programs, customizable parameters according to different product features to meet diverse needs.

Product Specifications

Product Advantages

Technical Specifications

Function Introduction

Application Scenarios

Contact Us for Customized Solutions

Fill out the form below and our professional technical team will contact you within 24 hours to provide tailored airtightness testing solutions.

Company Address

2nd Floor, Building 6, Shayih Environmental Protection Industrial Park, 496 Chuangcheng Road, Shajing Street, Bao'an District, Shenzhen

Contact Phone

+86 17376311087

wafubrother@outlook.com

wafubrother@gmail.com

WAFU

WAFU