Technical Resource Center

Explore our comprehensive technical articles and user guides to gain professional insights and practical tips in the field of airtightness testing.

Technical Articles

What Is a Waterproof Testing Machine?

If you are a factory owner and the products you manufacture require “waterproof” performance, you may have heard of “leak testers” and “waterproof testers”. The names sound self-explanatory, but what exactly is this device? Can it really meet my waterproof testing needs?

Traditional vs. Modern Waterproof Testing in Smartphones

Nowadays, the penetration rate of smartphones is extremely high—almost everyone owns at least one, and some people own more than one. The usage scenarios have expanded from ordinary daily life to various extreme and complex environments. Waterproof performance has become an important factor for most users when choosing a product. Whether it is accidental splashes in daily life, exposure to rain during outdoor use, or brief immersion caused by misuse, smartphones inevitably need to meet waterproof performance requirements. This performance directly impacts both the lifespan and safety of the device. To ensure products meet international waterproof standards such as IP67 and IP68, manufacturers must conduct rigorous waterproof testing before shipping. With technological advancement, smartphone waterproof testing methods have evolved from traditional to modern approaches, and the application of leak testing technology has greatly improved both accuracy and efficiency.

Leak Tester Buying Guide: Five Key Indicators You Can’t Ignore

In industrial production—especially in fields such as new energy vehicles, medical devices, consumer electronics, home appliances, and aerospace—the airtightness (waterproofness/sealing performance) of products is a crucial quality indicator. Choosing a suitable and reliable leak tester directly affects product quality, production cost, and operational efficiency. Faced with the wide variety of products on the market and persuasive sales pitches, how can you avoid pitfalls and select the most suitable equipment? This article reveals the five key indicators you must focus on during the selection process.

Waterproof Tester – How It Ensures Electronic Products Meet IP67/68 Standards

In today’s world, smartphones are almost indispensable, and wearable devices as well as smart home appliances are becoming increasingly popular. The waterproof performance of these devices has become a critical benchmark for both product quality and market competitiveness. Consumers now pay close attention to whether electronic products are certified with IP67 or IP68 waterproof ratings. This article explores how a waterproof tester plays a vital role in ensuring these IP protection levels.

Leak Tester too expensive? That’s because you don’t know these things!!!

Many business owners who just bought a leak tester may have faced this dilemma: products frequently returned due to leakage, so you decide to invest in a high-end leak tester. But when you unbox it, it doesn’t seem to have much “high-end” inside. Feels like wasted money? Don’t worry, as an engineer with over 10 years at WAFU Brothers, I’ll share how to choose a truly suitable, high cost-performance leak tester so every penny is well spent!

Using a smartphone leak test case, learn the working principle of a leak tester in just a few seconds

What is the principle of a leak tester? Most people may guess it’s related to “air leakage,” but don’t know how it can determine sealing performance within just a few seconds. Actually, a leak tester is not some unattainable technology. Today, through several smartphone leak testing cases, I’ll explain the working principle of leak testers!

How to perform leak testing and water immersion testing at the same time – WAFU Brothers’ new product solves it perfectly!!

In the field of industrial manufacturing quality testing, leak testers have already become mainstream equipment. They can precisely determine whether products have micro-leakage using pressure decay, flow measurement, and other methods. Compared with traditional water immersion testing, leak testing is not only more efficient but also presents leakage rate results in digital form, making it widely applied in automotive parts, medical devices, consumer electronics, and aerospace manufacturing.

Sealing Test Exposed! 80% of business owners don’t know whether to choose water testing or air testing!

In product sealing tests, choosing between water testing or air testing is a core challenge many business owners face. The choice of testing method not only affects detection accuracy but also directly impacts product quality and business costs. With 16 years of industry expertise, WAFU Brothers will quickly explain the key differences between the two methods and provide practical selection advice!

Don’t underestimate the airtightness testing of medical nebulizers — it could be a hidden killer in medical safety!

In the medical field, even the smallest component can be critical to patient safety, and the medical gas valve is one such vital part. Its performance directly affects the proper operation of medical equipment, and professional leak testing of medical gas valves is key to ensuring medical safety. Shockingly, even a tiny leak in a medical gas valve could result in devastating tragedies.

High-Precision Airtightness Testing Technology Analysis

In modern industrial production, high-precision airtightness testing is crucial for ensuring product quality, safety, and reliability. This article explores the core principles, main methods, and application scenarios of airtightness testing, while sharing the latest research achievements in this field.

Why Has the Airtightness Tester Become the Core Tool for Quality Control in Industrial Manufacturing?

In the field of industrial manufacturing, product quality is the cornerstone of a company’s market position. Airtightness, as a key performance indicator, directly affects safety, reliability, and product lifespan. From automotive fuel injection systems to waterproof smartphone bodies, from aerospace sealed cabins to household gas stoves, even the slightest leak can cause catastrophic consequences. Against this backdrop, the airtightness tester, with its precise and efficient testing capabilities, has rapidly emerged as the core tool for quality control in industrial manufacturing.

Micro-Leakage Early Warning: Breakthrough Applications and Future Trends of High-Precision Airtightness Testers

An in-depth analysis of the core technologies and application scenarios of high-precision airtightness testing, including the principles and comparative analysis of differential pressure testing, flow testing, and other methods.

How Airtightness Testing Builds a Strong Reliability Shield for Electronic Products

The core components of electronic products—precision circuits, microchips, and highly integrated modules—are like the “delicate heart” of the device. Once liquids (water, oil mist), gases (moisture), or particles (dust) breach the sealing defense, the consequences can range from short circuits and performance degradation to complete device failure.

Solving Roller Shutter Motor Waterproofing Challenges! WAFU Brothers’ 3 Core Testing Technologies Revealed

In both industrial and civil facilities, the waterproof performance of roller shutter motors is directly linked to equipment lifespan and operational safety. Industry data shows that water ingress accounts for 62% of motor failures, with each repair averaging 4 hours and costing over 1,000 RMB. Traditional methods (such as visual checks or immersion tests) are inefficient, prone to misjudgments, and may damage motors. Leveraging 15 years of testing expertise, WAFU Brothers has launched an intelligent waterproof testing solution for roller shutter motors, achieving “zero misjudgment, high efficiency, and extended service life” through three core technologies.

WAFU Brothers Leads the AI Smart Testing Era: Efficient and Accurate Airtightness Solutions

As manufacturing embraces digital transformation, airtightness testing—key to ensuring product quality—is shifting from human expertise to AI-driven intelligence. Building on 15 years of industry experience, WAFU Brothers pioneered an AI-powered airtightness solution integrating IoT and big data analytics. This system delivers “zero misjudgment, full traceability, and adaptive testing” for automotive parts, EV batteries, and medical devices, helping enterprises improve both quality and efficiency.

Frequent Rework in Sealing Tests? The Root Lies in the Testing System! WAFU Brothers Shows You How to Fix It

In manufacturing, rework caused by sealing tests is like a persistent “chronic disease”—draining profits and damaging brand reputation. A case study from a Ningbo auto parts manufacturer shows a rework rate of 8.7% in 2023, adding 4.2 million RMB in annual costs, accounting for 35% of their quality control spending. Many companies mistakenly blame production flaws, overlooking potential problems in the testing system itself.

How to Choose an Airtightness Tester? WAFU Brothers Explains Direct Pressure, Differential Pressure, and Flow-Type Principles

Airtightness testing is essential in industrial manufacturing, and choosing the right tester is crucial. WAFU Brothers offers direct pressure, differential pressure, and flow-type testers, each designed for specific applications. This article provides a detailed explanation of their principles and methods, helping enterprises make informed choices.

From Water Tests to Air Tests: WAFU Brothers Revolutionize Sealing & Waterproof Detection

Sealing and waterproof testing is the final defense line in manufacturing quality control. From manual water testing to precise air testing, technological upgrades are reshaping industry standards. WAFU Brothers has broken traditional limitations with innovative R&D, creating an all-scenario testing system that redefines “zero leakage.”

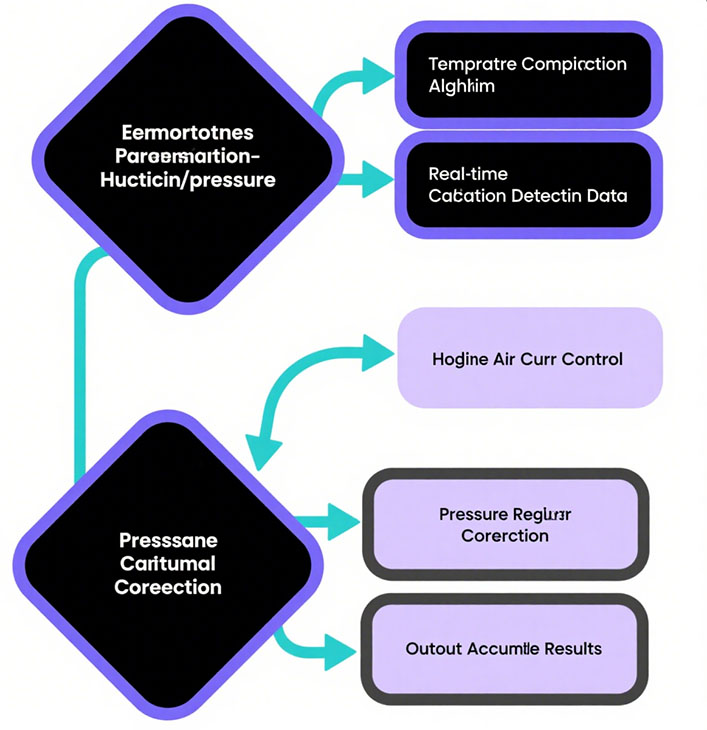

How Do Environmental Factors Affect Airtightness Testing?

In industrial product sealing tests, airtightness verification is a critical step for ensuring product safety and reliability. However, environmental factors such as temperature fluctuations and noise interference can significantly impact results. Drawing on 16 years of industry expertise, WAFU Brothers explains in detail how these factors affect testing and how to overcome them.

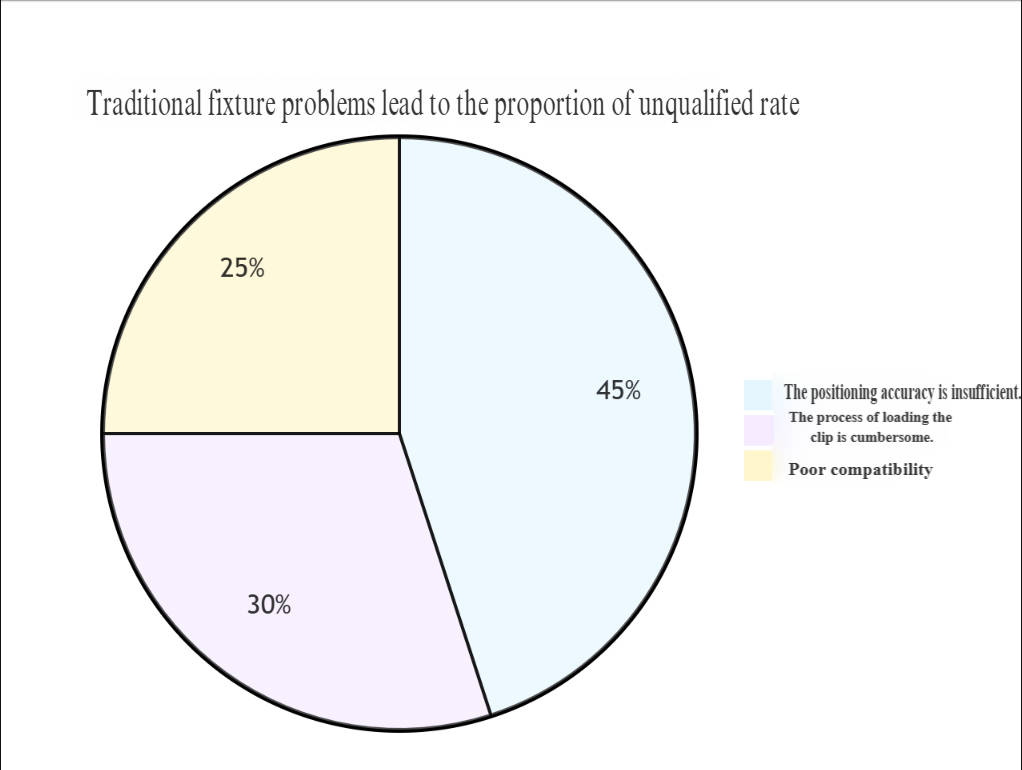

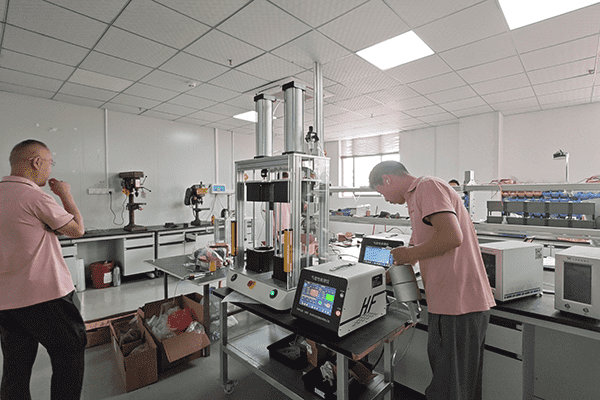

WAFU Brothers’ Innovative Fixture Design: Breaking Airtightness Testing Bottlenecks and Ensuring Stability

In airtightness testing, fixtures act as the “bridge” between the tester and the workpiece, directly impacting efficiency and data stability. From automotive parts mass production to precise medical device testing, traditional fixtures often cause misalignment, long setup times, and poor adaptability—leading to inefficiency and unstable results. Leveraging over a decade of expertise, WAFU Brothers developed high-performance fixtures with innovative designs and advanced technology, solving industry pain points and becoming a key driver for higher efficiency and stability.

All-Scenario Airtightness Testing Solutions: Safeguarding the Final Quality Control Barrier

In modern manufacturing, final factory inspection is not only the last line of quality control but also vital to brand reputation. With increasingly precise industrial processes, traditional methods struggle to catch micro-leakage. Backed by years of expertise, WAFU Brothers introduced an all-scenario airtightness solution, helping manufacturers ensure “zero leakage” before shipment.

Overcoming Thermal & Noise Barriers: WAFU Brothers Achieves Non-Destructive Smart Sealing Tests

As industrial manufacturing advances toward high-end and intelligent processes, sealing tests have become a core technology to ensure product quality, widely used in automotive, aerospace, and medical industries. With ever-increasing machining precision, high-accuracy airtightness testers directly affect product safety and performance. However, accuracy is often limited by sensor performance, testing methods, temperature variations, and noise interference.

WAFU

WAFU