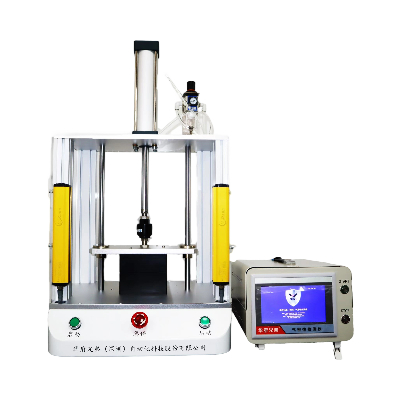

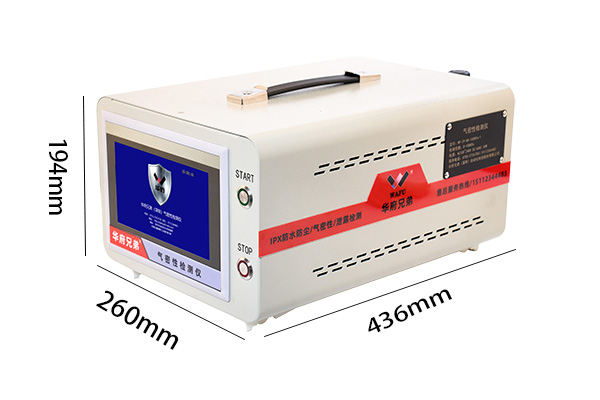

Flow-Type Airtightness Tester

High-precision sealing performance testing equipment, providing reliable airtightness solutions for automotive, electronics, medical, and other industries.

Actual price depends on product customization

Product Introduction

- HF Series 6th Generation is an airtightness testing device centered around a high-sensitivity flow sensor, specially designed to address challenges in waterproof breathability and micro-flow detection.

- It uses the instantaneous flow loss method to accurately detect air leakage, breathability, waterproof breathability performance, and leakage rate, without requiring volume or leakage threshold calculations, greatly simplifying operation and improving efficiency and stability.

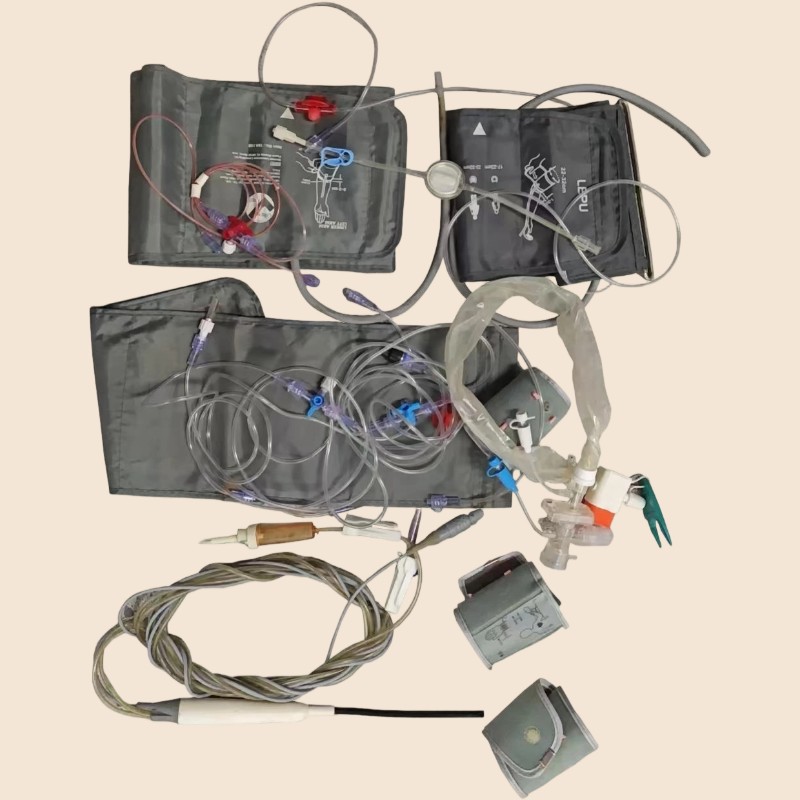

- This device is especially suitable for IPX4, IPX5, IPX6 medium to low protection level tests, as well as various scenarios requiring clear "breathability" requirements, such as infusion tubes, capillary copper tubes, acoustic speakers, waterproof breathable membranes, and other parts flow evaluation and testing.

- With high response and precision flow sensing capabilities, the HF 6th generation excels in complex scenarios combining breathability and waterproofing, making it an ideal quality control tool for medical consumables, consumer electronics, automotive parts, and more.

Quality Assurance

Our products ensure testing quality and user experience through multiple core features.

Wide Applications

75° Adjustable Viewing Angle

Higher Precision

High Sensitivity

Stable Anti-Interference

Customized Solutions

Product Details

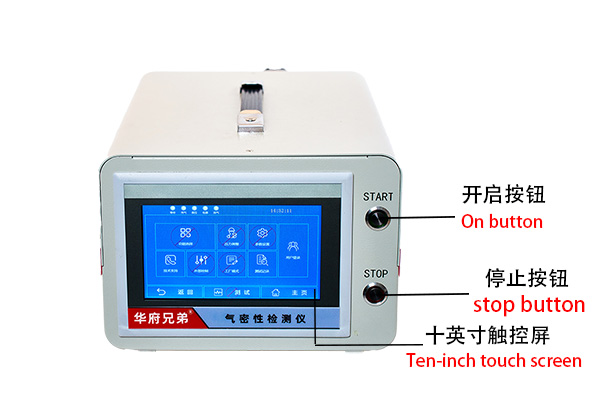

Appearance and Interaction Design

Full Metal Body Design

High-strength aluminum alloy housing with precision machining and surface treatment, strong anti-interference capability, suitable for long-term use in industrial environments.

7-inch HD Touch Screen

Simple and intuitive user interface with multi-language support and guided instructions, enabling faster operator onboarding.

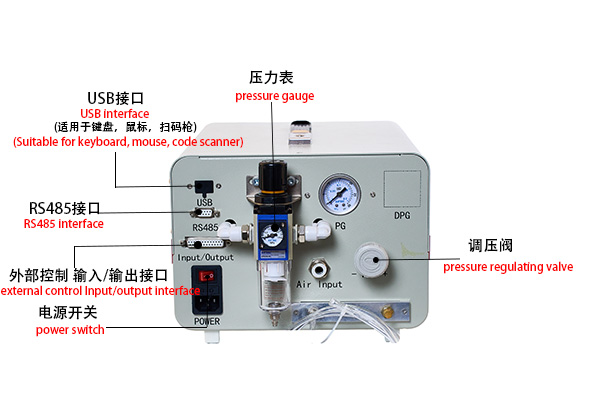

Rich Interface Configuration

Equipped with RJ45, USB, mouse and other communication ports, facilitating integration with other equipment for automated testing processes.

Operating System & UI Screens

Pressure Setting Screen

Instrument UI Screen

Testing Technologies and Methods

Test Composition

Includes air source treatment unit, pressure regulation module, and precision sensors, forming a complete closed-loop detection system.

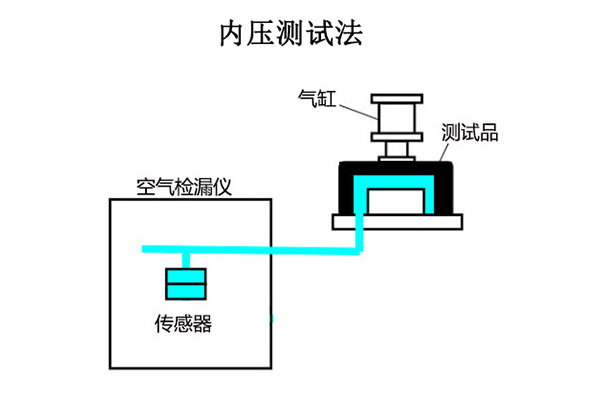

Internal Pressure Test Method

By filling the tested part with a specific pressure gas, the sealing is judged by monitoring pressure changes; suitable for enclosed cavity testing.

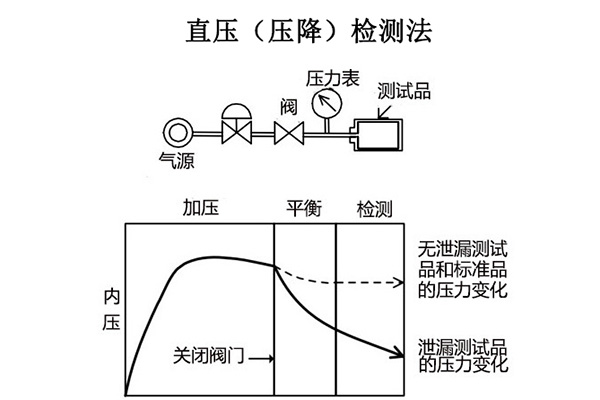

Direct Pressure (Pressure Drop) Test Method

Directly apply test pressure and monitor pressure decay; suitable for production scenarios with higher testing speed requirements.

Core Advantages

High-Precision Testing

Uses imported high-precision pressure sensors (accuracy ±0.1% F.S) and 24-bit AD acquisition chips, achieving sensitivity up to 0.1Pa to ensure accurate and reliable results.

High Testing Efficiency

Optimized inflation and testing process combined with fast-response sensor system allows single product testing cycle shortened to under 1 second, boosting production efficiency.

Flexible Testing Modes

Supports both positive and negative pressure testing modes, with multiple built-in test programs and customizable parameters to meet diverse product requirements.

Product Specifications

Technical Specifications

| Number of Channels: | 1 |

| Pressure Types: | Positive, Negative, Both |

| Pressure Regulation Mode: | Manual/Automatic |

| Pressure Regulation Accuracy: | ± 0.05% FS |

| Pressure Repeatability: | 0.1% FS |

| Pressure Range: | -95 KPa – +3000 KPa |

| Sensor Range: | -95 KPa – +3000 KPa |

| Sensor Accuracy: | 0.1% FS |

| Resolution: | 0.1 Pa |

Features

| Touch Screen: | 7-inch Color LCD |

| UI Interface: | WAFU UI |

| Languages: | Chinese, English, Japanese (customizable) |

| Program Groups: | 16 / 99 groups |

| Judgment/Alarm: | Auto Judgment / Audio-Visual Alarm |

| Communication Interface: | RS485, USB |

| History Records: | Stores up to 100,000 entries, supports USB export |

Application Scenarios

Contact Us for Customized Solutions

Fill out the form below, and our professional technical team will contact you within 24 hours to provide a tailor-made airtightness testing solution.

Company Address

2nd Floor, Building 6, Sha Yi Environmental Protection Industrial Park, 496 Chuangcheng Road, Shajing Street, Bao’an District, Shenzhen

Contact Number

+86 17376311087

Email Address

wafubrother@outlook.com

wafubrother@gmail.com

WAFU

WAFU