Leak Testing for Hardware Die-Casting Parts

Wafu Brothers plays a vital role in leak testing within the hardware die-casting industry, providing high-precision testing equipment. Their technology is widely applied in leak testing of hardware die-cast parts, ensuring the leak of various metal housings and structural components; used for leak detection of valve bodies and pump bodies, guaranteeing operational safety; and also supports automotive housing leak testing and power tool housing testing, enhancing product reliability and service life. Wafu Brothers offers reliable assurance to the hardware die-casting industry with advanced technology, becoming an important partner for die-cast manufacturers.

Die-Cast Mold Components

Inherent process-related internal defects: During high-temperature, high-speed filling in die casting, hidden defects such as porosity, shrinkage cavities, and micro-cracks may inevitably occur inside the part.

Extremely high sealing requirements during mold operation: As molds, die-cast mold components often need to withstand pressure media and operate long-term under vacuum or alternating positive and negative pressure conditions.

Ensuring service life: Some sealing issues in die-cast mold components do not appear immediately during production but gradually surface with increased usage, eventually leading to mold scrapping or production downtime for maintenance.

Safeguarding product forming accuracy: Once leakage occurs in a die-cast mold component, it directly affects pressure distribution and forming conditions within the mold cavity, leading to molding defects.

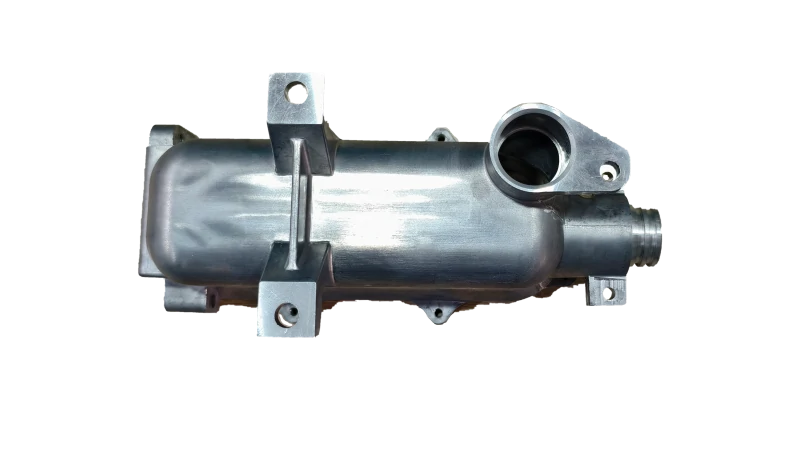

Stern Cover Hardware Die-Casting Part

Key structural component: critical metal structure at the ship’s stern, made of aluminum or magnesium alloy die-casting.

Multiple functions: covers and protects underwater components such as propellers, rudders, and stern shafts, providing flow guidance, corrosion protection, and shock absorption.

High leak requirement: long-term underwater operation demands extremely high leak; even minor leaks may cause internal component water ingress and failure.

Impact on ship safety: leaks may cause water ingress into motors, transmission mechanisms, and bearing lubrication systems, severely affecting ship safety.

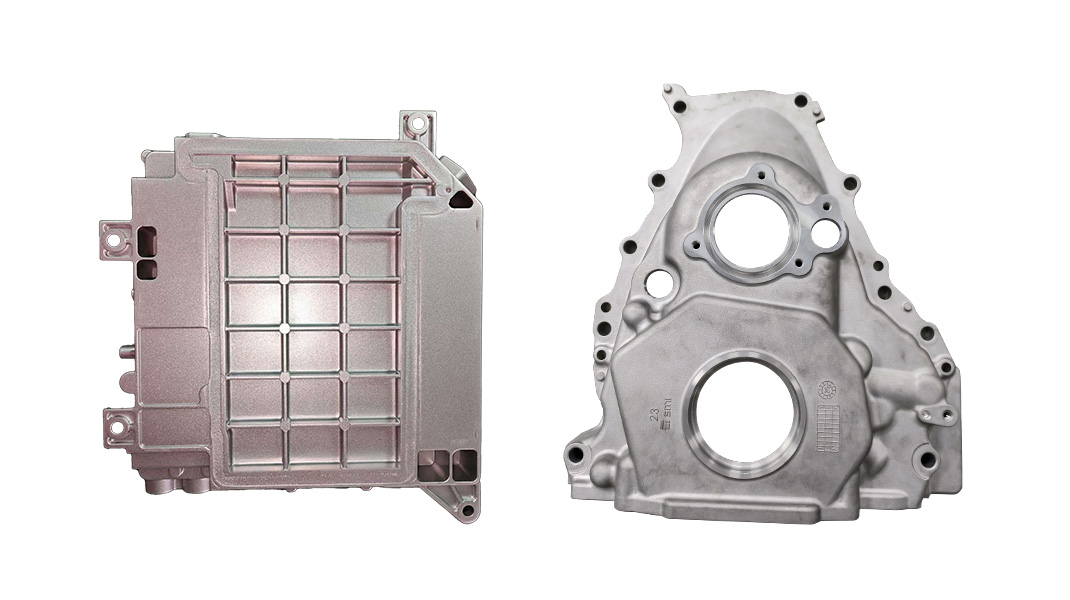

Automotive Die-Cast Components

1. Inspection Area: The sealing performance of the entire cavity of the die-cast component.

2. Multiple Functions: Prevents engine malfunctions caused by poor sealing, reduces customer complaints and repairs, and improves customer satisfaction.

3. High Leak Requirements: Operates under high-pressure conditions with extremely strict leak demands. Even minor leaks may reduce internal performance.

4. Impact on Driving Safety: Poor sealing may cause oil and gas leakage inside the engine compartment, leading to reduced engine performance, increased fuel consumption, and even potential safety hazards.

LED Lamp Base Metal Die-Casting Parts

1. Inspection Area: The leak of the entire die-casting part.

2. Multiple Functions: Prevent reduced waterproof performance of the LED lamp caused by poor sealing, which could allow moisture and water vapor to penetrate.

3. High Leak Requirements: In outdoor working environments, insufficient leak may allow rainwater to enter the metal parts, leading to oxidation, corrosion, and compromising structural strength and appearance.

4. Safety Impact: Water ingress may cause the circuit board to become damp, potentially leading to electric leakage, short circuits, or even fire, posing a serious safety risk.

WAFU

WAFU