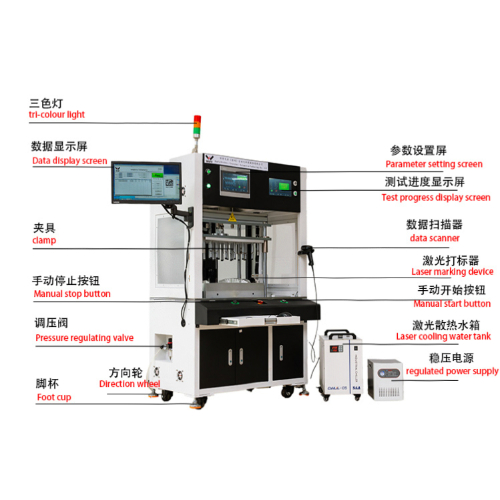

Cabinet Leak Tester

High-precision sealing performance testing equipment, providing reliable airtightness solutions for automotive, electronics, medical and other industries.

Pricing depends on the tested product requirements

Product Introduction

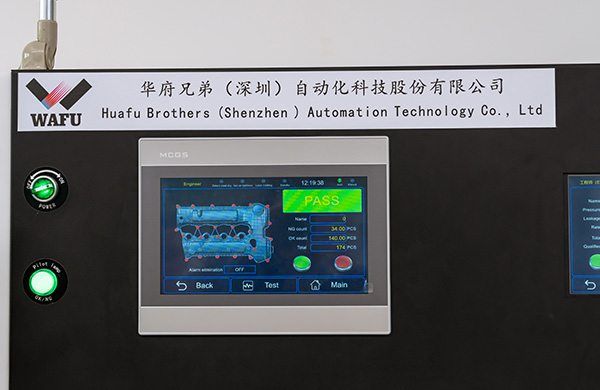

- Cabinet Airtightness Tester is the all-around guardian for automotive engine cover sealing tests. It integrates intelligent detection, precise identification, and data management to fully safeguard product quality and production safety.

- The device features automatic detection of missing screw rings and can accurately test the overall airtightness of engine covers, strictly controlling every sealing protection step. Equipped with a fully automatic laser marking machine for clear and efficient traceability marks; integrated with MES system seamless connection, the upper computer automatically saves test data, facilitating efficient production information closure.

- Powerful configuration: high-precision airtightness detection module, industrial-grade control PC, imported barcode scanner for scanning input, simple operation, and reliable data retention. Built-in multiple safety protection mechanisms to eliminate operational hazards and ensure personnel safety.

- With this device, automotive engine cover testing becomes smarter, faster, and more reliable, helping enterprises easily step into the new era of intelligent manufacturing.

Product Advantages

Our airtightness testers offer comprehensive solutions with outstanding performance and innovative technology.

Excellent Quality

Made of high-quality materials for long-lasting durability

High Cost Performance

Outstanding performance at a reasonable price

Precision & Efficiency

High detection accuracy with fast speed

Quality Assurance

Strict quality control for reliable performance

Fully Automatic Mode

Intelligent operation reduces manual intervention

Product Details

Core Hardware Configuration

Industrial-grade Cabinet Enclosure

High-strength aluminum alloy integrated casing with anti-corrosion treatment; internal partitioned cooling design, suitable for long-term operation in industrial environments from -10℃ to 40℃.

Ergonomic Structural Design

Operation panel tilted at 15°, matching standing eye-level; reserved integration ports support seamless production line connection.

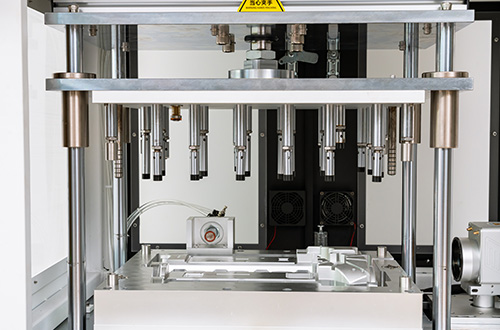

Custom Testing Fixtures

Exclusively designed according to product shape, equipped with quick positioning structure; repeat positioning accuracy ≤0.05mm to ensure testing consistency.

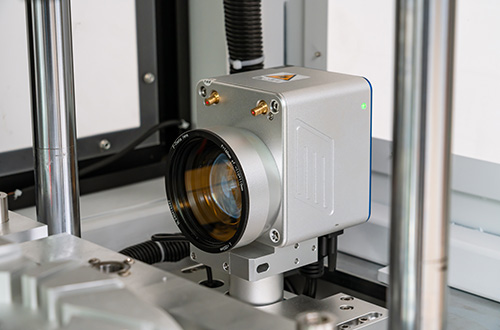

Integrated Laser Marker

10W fiber laser module supporting QR code/serial number marking; linked with testing system to automatically mark qualified products.

High-Definition Display Screen

24-inch screen with 1920×1200 resolution; supports real-time display of testing curves, making data visualization more intuitive.

Industrial-grade Scanning System

Imported image-based scanning head supporting DPM code recognition; scanning speed ≤0.1s, capable of associating product batch information.

Intelligent Cooling Water Tank

Closed-loop water cooling system with automatic flow adjustment; water temperature control accuracy ±1℃, ensuring continuous laser module stability.

Precision Stabilized Power Supply

Wide input range 110-240V, output accuracy ±0.5%; equipped with overcurrent/overvoltage protection to prevent sensor damage from power fluctuations.

Operating System and UI Interface

Intelligent Pressure Setting System

Supports segmented pressure settings with up to 16 preset process parameters; includes pressure pre-judgment to avoid overpressure damage to workpieces.

Visual Operation Interface

WAFU UI interactive design simplifies operation steps by 30%; real-time display of test curves with automatic marking of nonconformities.

Core Advantages

High-Precision Detection

Uses imported high-precision pressure sensors (accuracy ±0.1% F.S) and 24-bit AD acquisition chips. Detection sensitivity reaches 0.1Pa, ensuring accurate and reliable test results.

High-Efficiency Testing Speed

Optimized inflation and testing process design combined with fast-response sensor systems reduce single product test cycle to under 1 second, improving production efficiency.

Flexible Testing Modes

Supports both positive and negative pressure testing modes with built-in multiple test programs. Testing parameters can be customized based on different product characteristics to meet diverse requirements.

Product Specifications

| Technical Specifications | |

|---|---|

| Dimensions | 1100×810×1800 (mm) |

| Model | WF-ZY-KK—100Kpa-1 |

| Name | Wafu Brothers Airtightness Tester |

| Power Supply | AC 200-240V 50W |

| Testing Range | 100Kpa |

| Testing Accuracy | 1Pa |

| Air Supply Pressure | 0.4-0.8Mpa |

| Barcode Scanning | Optional barcode scanning and printing functionality; supports storage of 300,000 historical records and batch export. |

| Automated Fixtures | Optional fully automated fixtures available; supports customizable channel quantity to improve testing efficiency. |

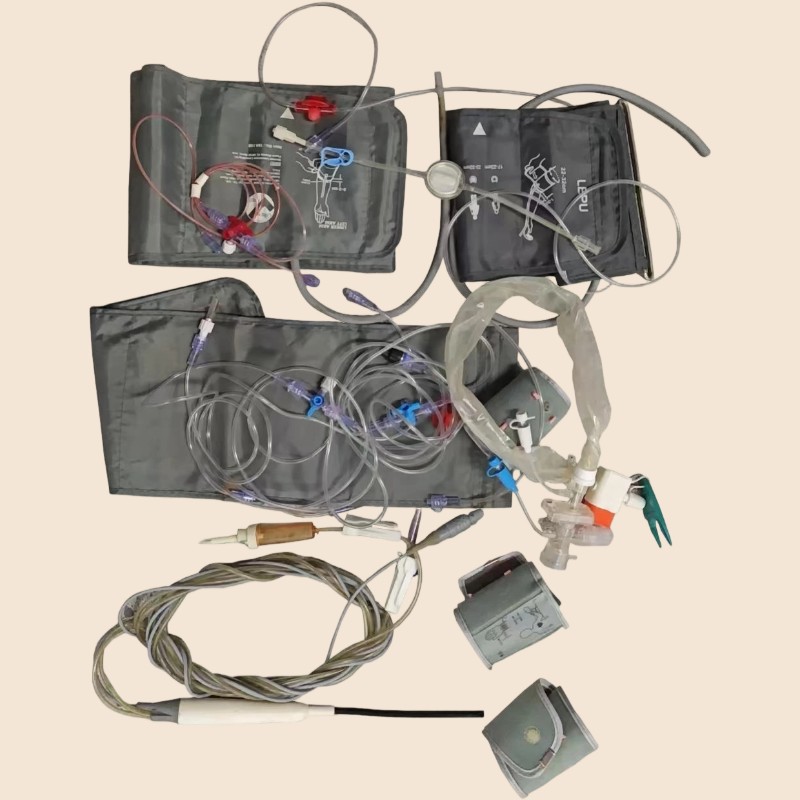

Application Scenarios

Contact Us for Customized Solutions

Fill out the form below, and our professional technical team will contact you within 24 hours to provide tailored airtightness testing solutions.

Company Address

2nd Floor, Building 6, Sha Yi Environmental Protection Industrial Park, 496 Chuangcheng Road, Shajing Street, Bao'an District, Shenzhen

Contact Number

+86 17376311087

wafubrother@outlook.com

wafubrother@gmail.com

WAFU

WAFU