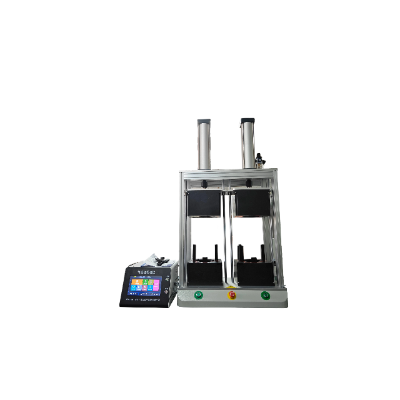

Custom Leak Tester

High-precision sealing performance testing equipment providing reliable leak solutions for automotive, electronics, medical, and other industries.

Pricing depends on the testing product requirements

Pricing Inquiry Tips

Please provide the following information in your inquiry so that we can offer you a more accurate quote:

- Type and size of the product to be tested

- Expected testing accuracy and pressure range

- Whether automated testing functionality is needed

- Estimated annual production volume and production line requirements

Quality Assurance

Our products ensure testing quality and user experience through multiple core features

Suitable for Multiple Scenarios

75° Adjustable Viewing Angle

Higher Precision

High Sensitivity

Stable and Anti-interference

Personalized Customization

Product Details

Product Types

Drinking Water Tank

Rubber Ring

Steamer Inner Pot

Plastic Connector

Core Advantages

High Precision Testing

Uses imported high-precision pressure sensors (accuracy ±0.1% F.S) and 24-bit AD acquisition chips, achieving sensitivity up to 0.1 Pa, ensuring accurate and reliable test results.

High Testing Speed

Optimized inflation and testing process design combined with fast-response sensor systems, reducing the testing cycle per product to under 1 second, improving production efficiency.

Flexible Testing Modes

Supports both positive and negative pressure testing methods, with multiple built-in test programs. Customizable parameters allow adapting to different product characteristics and diverse needs.

Product Parameters

Product Advantages

| Touchscreen | 7/10-inch touchscreen, supports positive/negative pressure tests, both open and sealed methods |

| Display Units | Pa, KPa, MPa, Kg, Bar and leakage units |

| Core Performance | Second-generation upgraded product, internationally high-sensitivity sensor, industry-leading accuracy of 0.02% |

| Channel Configuration | 32-channel design, supports quick parameter channel selection and setting |

| Control Capability | Multi-channel I/O control, supports manually adjustable output terminals |

| Test Modes | Manual/automatic dual modes, supports pressure sequence testing |

| Remote Control | Rich interfaces for PLC connection, direct external device control |

| Intelligent Technology | AI statistical technology, automatically collects pressure/time parameters |

| Sensor | High-precision sensor, automatic calibration, 0.001 Pa resolution |

| IoT | Supports remote management and quality traceability, connectable to MES systems |

Technical Parameters

| Number of Channels | 1/2/4 |

| Pressure Types | Positive pressure, negative pressure, both positive and negative pressure |

| Adjustment Mode | Manual adjustment / automatic adjustment |

| Adjustment Accuracy | ±0.02%FS ~ ±0.05%FS |

| Pressure Repeatability | 0.1%FS |

| Adjustment Range | -60 KPa ~ 1MPa |

| Sensor Range | 0 ~ 50L/min |

| Sensor Accuracy | ±1%FS |

| Resolution | 0.001 ml/min ~ 1 ml/min |

Feature Introduction

| Touchscreen | 7/10-inch color LCD |

| Operating Interface | WAFU UI |

| Language Support | 6 languages including Chinese, English, Japanese (customizable) |

| Number of Programs | 16/99 program groups |

| Alarm Function | Automatic judgment with audio and visual alarms |

| I/O Ports | 4 relay controls (safety fence, solenoid valves, etc.) |

| Communication Interface | RS485 (PLC control / workstation connection) |

| USB Functions | Software updates / barcode scanner connection |

| History Records | 100,000 records stored, supports USB export |

Product Parameters

| Technical Parameters | |

|---|---|

| Dimensions | 1100×810×1800 (mm) |

| Model | WF-ZY-KK—100Kpa-1 |

| Name | WAFU Brothers Leak Tester |

| Power Supply | AC 200-240V 50W |

| Testing Range | 100 KPa |

| Testing Accuracy | 1 Pa |

| Air Supply Pressure | 0.4-0.8 MPa |

| Barcode Scanning | Optional barcode scanning and printing functions, supports storage of 300,000 records and batch export |

| Automatic Fixture | Optional fully automated fixture, customizable channel number, improves testing efficiency |

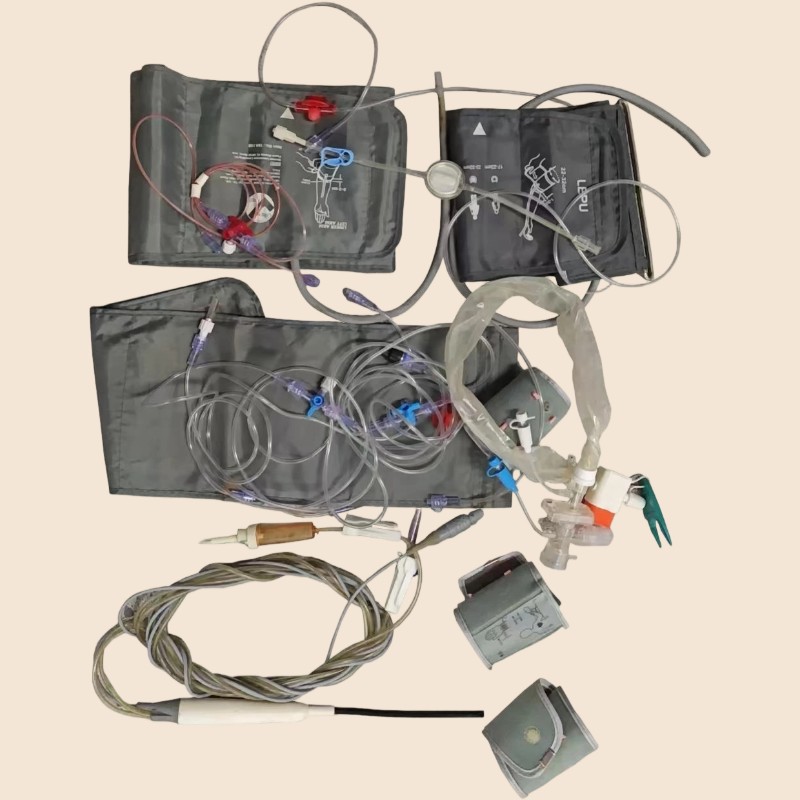

Application Scenarios

Contact Us for Customized Solutions

Fill out the form below, and our professional technical team will contact you within 24 hours to provide tailor-made leak testing solutions.

Company Address

2nd Floor, Building 6, Sha Yi Environmental Protection Industrial Park, 496 Chuangcheng Road, Shajing Street, Bao'an District, Shenzhen

Contact Number

+86 17376311087

wafubrother@outlook.com

wafubrother@gmail.com

WAFU

WAFU