Electronics Industry Testing Case

Wafu Brothers provides leak testers that are crucial in electronic devices, ensuring waterproofing, dustproofing, and durability. Through leak testing technology, the company accurately tests product sealing performance to prevent air leakage issues. Whether it's pressure leak testing or micro-leak detection, efficient solutions are offered. Using non-destructive testing guarantees waterproof performance and prevents failures, while the company's automated leak testing system improves testing efficiency and ensures quality control.

Camera Front Cover

Ensure image quality is not affected: Impurities entering the module can directly adhere to the sensor or lens, causing permanent damage to the image quality.

Increase product lifespan: Corrosive substances exist in daily environments. A good seal protects the internal precision parts, preventing chemical erosion that may degrade performance.

Intercept assembly defects: Assembly relies on precise dispensing and pressing, and any deviation in these processes can create leakage channels.

Reduce costs and brand loss: Parts that fail leak testing, if allowed to proceed, can cause multiple times the after-sales repair costs and damage to brand reputation.

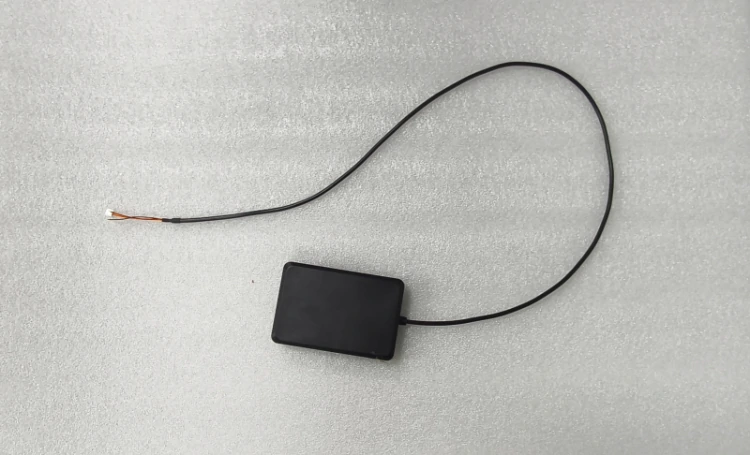

GPS Tracker

Waterproof and dustproof: Commonly used in complex environments such as outdoors, vehicles, logistics containers, and pet collars, where it may be exposed to rain, dust, mud, and other contaminants.

Prevent moisture corrosion of electronic components: The tracker contains precision circuits and communication modules. Poor sealing allows moisture in the air to gradually penetrate, leading to circuit board corrosion.

Adaptation to extreme temperatures: The device may experience high and low temperature cycles during use. Good leak tightness helps prevent moisture or contaminants from being drawn in due to the “breathing effect” caused by thermal expansion and contraction.

Improved durability: GPS trackers usually need to operate continuously for long periods and may not be disassembled or maintained for years.

E-Cigarette E-Liquid Tank

Prevent oil leakage: If the tank is poorly sealed, e-liquid may leak from gaps or interfaces. This not only causes product waste but may also contaminate other electronic components, affect normal device operation, and even pose a risk of short circuits.

Avoid oxidation and degradation: The main components of e-liquid may oxidize or volatilize when exposed to air, leading to flavor deterioration, changes in nicotine concentration, or even the formation of harmful substances.

Ensure stable atomization: E-cigarettes generate aerosol by heating e-liquid through an atomizer. If the tank’s sealing integrity is insufficient, external air may enter abnormally, resulting in unstable atomization pressure and affecting the consistency of vapor output and taste.

Safety assurance: For nicotine-containing e-liquids, leakage may cause skin contact or accidental ingestion, posing toxic risks—especially to children and pets.

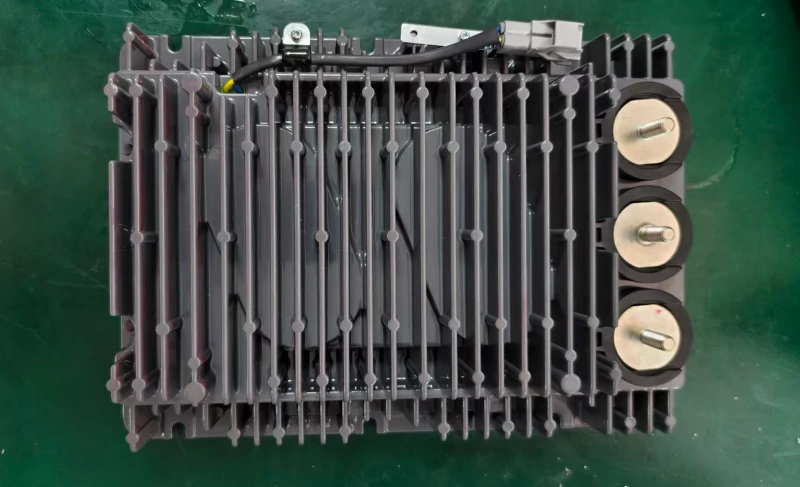

Energy Storage Controller

Harsh Operating Environment: Energy storage controllers are usually installed outdoors or in renewable energy systems. Long-term exposure to rain, temperature fluctuations, and other conditions.

Protect Core Electronic Components: The controller integrates electronic components inside. If sealing is inadequate, moisture may enter and cause circuit corrosion.

Reduce Risk of Accidents: With high energy density, controller failure may lead to uncontrolled charging/discharging, seriously affecting the safety of the entire energy storage system.

Improve Product Quality: Leak testing can promptly identify assembly or manufacturing defects, reduce batch defects, and save labor and repair time.

Phone/Tablet/Laptop Housing

Protection certification: must meet IP67/IP68 standards to ensure waterproof and dustproof performance.

Safety hazards: poor sealing may cause water ingress into motherboard or battery, leading to short circuits and corrosion failure.

Production risk: integrated metal structures require airtight seams without false seals; otherwise, products cannot ship, causing huge losses.

Project schedule: failed sealing tests in the pilot production phase can delay mass production and postpone project timelines.

Electric Toothbrush

Challenges in humid environments: must ensure sealing performance under prolonged exposure to moisture, water immersion, and vibration.

Safety hazards: water ingress into main control circuit boards or batteries can cause failures, corrosion, short circuits, overheating, or explosions.

Certification requirements: failure to pass IPX6/IPX7 waterproof certification will prevent product launch.

Brand impact: frequent after-sales issues severely affect user reputation and decrease brand trust.

Bluetooth Headphones

Protection of delicate components: compact structure integrating battery, speaker, microphone, circuit board, and other delicate parts.

Daily environmental challenges: often exposed to sweat, rain, and moisture during use, requiring leak prevention.

Performance impact: poor sealing causes short circuits, corrosion, and sound distortion; moisture in batteries may lead to safety risks.

Bluetooth Earphone Charging Case

Waterproof and moisture-proof requirements: Often carried around, easily exposed to sweat, rain, and humidity.

Battery safety requirements: Built-in lithium battery with very high sealing requirements.

Product quality enhancement: Helps companies ensure compliance with the advertised waterproof rating standards.

Outdoor Camera

Prevent moisture and dust from entering: If the camera housing is not properly sealed, moisture or dust may get inside, causing lens fogging or sensor damage.

Ensure electronic component stability: Electronic components are very sensitive to moisture and dust. Even a small amount of vapor can cause corrosion, short circuits, or signal interference.

Meet waterproof rating standards: Outdoor cameras usually need to meet certain protection levels before leaving the factory, such as IP65, IP66, or IP67.

Improve user experience: Poor sealing may cause blurred images or frequent malfunctions, affecting the overall user experience.

Electric Handheld Toothbrush

Prevent water damage: Car washing involves heavy water flow and strong splashes. If the sealing is poor, water may enter the motor chamber, battery compartment, or control board.

Ensure user safety: Water entering the circuitry may cause electric leakage, posing safety hazards to users. Therefore, reliable sealing is essential.

Market requirements: Many electric cleaning tools must meet IPX6 (strong water jet protection) and IPX7 (temporary immersion protection) standards.

Improve durability: Good sealing prevents internal metal parts from corroding, motors from rusting due to moisture, and brush transmission structures from aging or jamming, thereby greatly extending the service life.

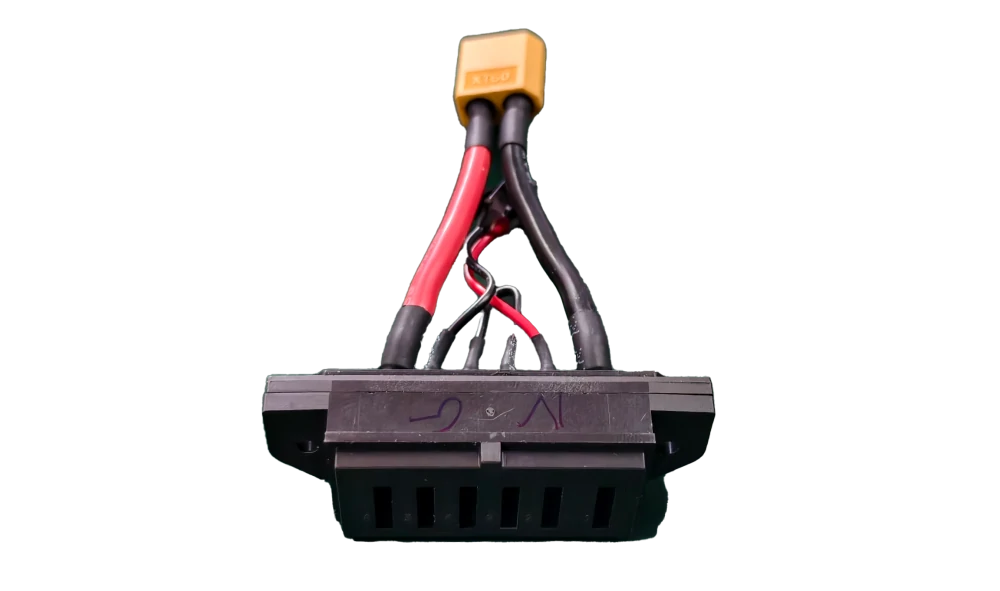

Wire Harness Connector

Prevent liquid ingress: In humid or liquid environments, moisture may enter if there is leakage inside the harness or at the connector interface.

Ensure electrical safety and performance: Air leakage or water ingress may lead to short circuits, signal interference, or electrical failures.

Handle harsh working conditions: Many components in modern vehicles and equipment operate in extreme environments.

Meet industry standards: High-end electronics, automotive, and aerospace equipment require strict waterproof, dustproof, and leak-proof specifications.

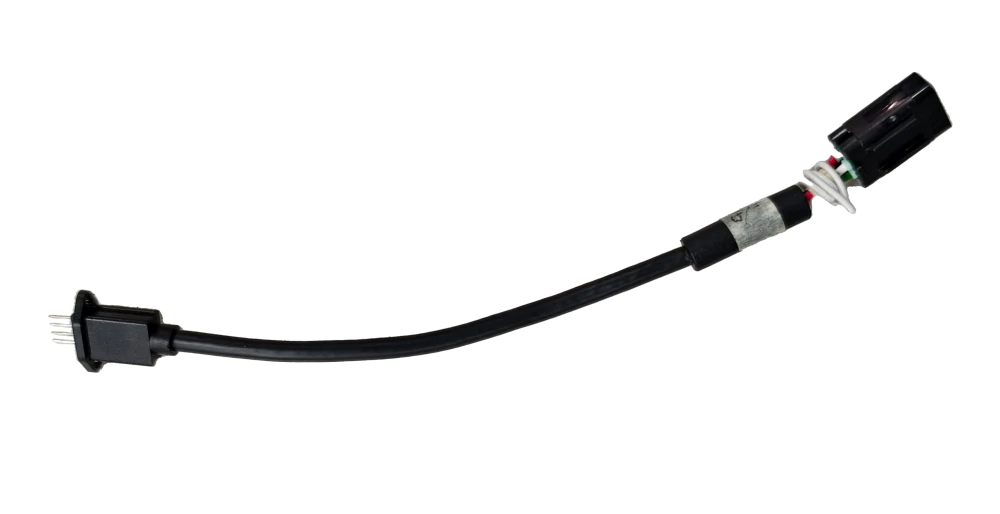

Electronic Cable

Moisture and corrosion protection: Oxygen, salt (in marine or coastal environments), and industrial gases (such as sulfides) can corrode internal metal conductors, solder joints, and contacts.

Ensuring signal integrity: Moisture intrusion may alter the characteristics of dielectric materials, resulting in impedance changes, signal reflection, and increased loss.

Extending product lifespan and reliability: Airtight cables effectively prevent harmful external substances from entering, fundamentally reducing early failures caused by environmental factors.

Sealing design in product structure: If an electronic cable adopts over-molding, rubber sealing rings, adhesive potting, waterproof terminals, or similar structures, leak testing is required to verify whether the sealing is truly effective.

WAFU

WAFU