Differential Pressure Leak Tester

High-precision sealing performance testing equipment, providing reliable airtightness solutions for automotive, electronics, medical, and other industries.

Final pricing depends on product customization.

Product Overview

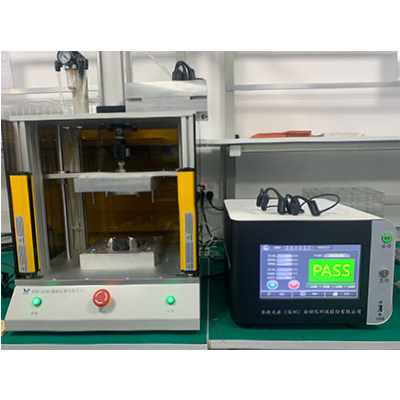

- The WAFU Brothers 5th Generation Differential Pressure Air Tightness Tester is a high-precision, non-destructive testing device. It uses compressed air as the medium to apply pressure to the inner cavity or outer surface of the product, and then detects pressure changes with high-sensitivity sensors to determine the product’s sealing performance.

- Since it uses compressed air, there's no secondary contamination to the product. It offers faster and more accurate testing compared to water-based methods (air molecules are smaller and leak faster), making it ideal for high-efficiency leak detection on production lines.

Product Advantages

Our airtightness testers offer comprehensive solutions with outstanding performance and innovative technology.

Superior Quality

Made with high-quality materials for long-lasting durability.

Cost-effective

Excellent performance at a reasonable price.

High Precision & Efficiency

High detection accuracy and fast testing speed.

Quality Assurance

Strict quality control ensures reliable performance.

Fully Automatic Mode

Smart operation minimizes manual intervention.

Key Advantages

High Precision Testing

Equipped with imported high-precision pressure sensors (±0.1%F.S accuracy) and 24-bit AD acquisition chips, the device achieves a sensitivity of 0.1 Pa, ensuring accurate and reliable test results.

High-Speed Detection

Optimized inflation and testing process, combined with a fast-response sensing system, allows each test cycle to be completed in under one second, significantly boosting production efficiency.

Flexible Testing Modes

Supports both positive and negative pressure testing. With built-in testing programs, users can customize parameters according to specific product characteristics to meet diverse requirements.

Product Specifications

Product Advantages

| Parameter Setting | Detection parameters can be customized for different product requirements |

| Testing Function | One-touch automatic detection with status indication (green: pass / red: fail) |

| Signal Interfaces | Equipped with various I/O ports; supports PC, barcode scanners, and more |

| Data Storage | Automatically generates test record folders for data management and traceability |

| Touchscreen | 7-inch Weizen LCD touchscreen with customizable UI |

| Core Components | Uses professional components from Japan, Germany, and Taiwan to ensure precision and stability |

| Communication Ports | Built-in RS232, RJ45 Ethernet, USB, and more |

| Pressure Range | -80 KPa to 2000 KPa, patented high-pressure solenoid valve prevents leakage |

| Resolution | 24-bit AD conversion with 0.02 Pa sensitivity |

| Basic Specs | Size: 400×330×200 mm, Weight: approx. 14 kg, Power: AC 220V 50/60Hz |

Technical Parameters

| Channel Count | 1 / 2 / 4 |

| Pressure Type | Positive, Negative, or Combined |

| Pressure Adjustment Mode | Manual / Automatic |

| Pressure Regulation Accuracy | ± 0.05%FS |

| Pressure Repeatability | 0.1%FS |

| Pressure Range | -95 KPa to +3000 KPa |

| Sensor Range | -95 KPa to +3000 KPa |

| Sensor Accuracy | 0.1%FS |

| Resolution | 0.1 Pa |

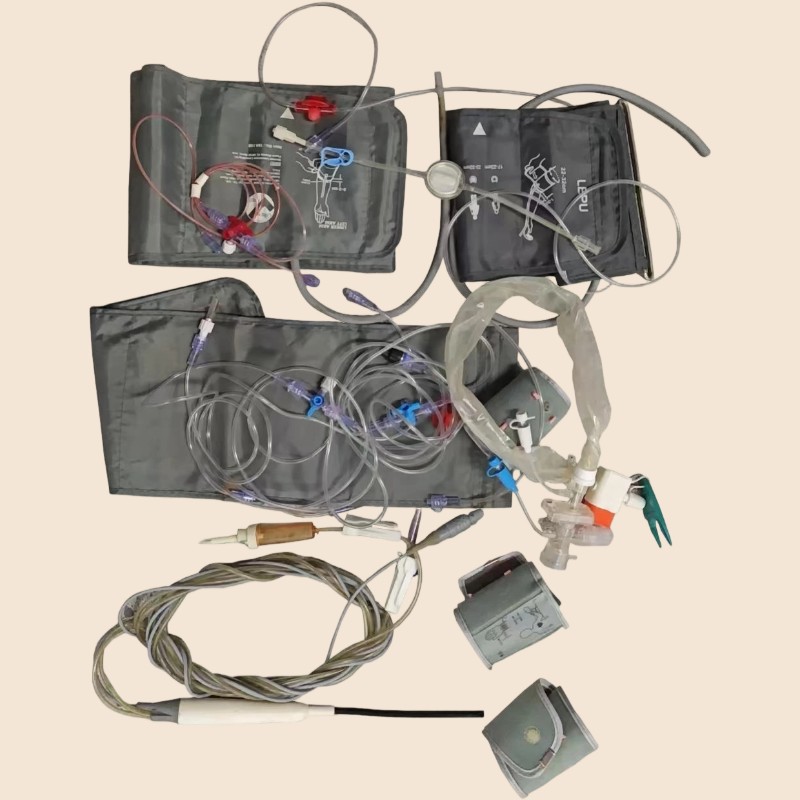

Application Scenarios

Contact Us for a Customized Solution

Fill out the form below and our technical experts will get in touch within 24 hours with a tailored airtightness testing solution.

Company Address

2F, Building 6, Shayi Environmental Industrial Park, No. 496 Chuangcheng Road, Shajing Street, Bao'an District, Shenzhen

Phone Number

+86 17376311087

wafubrother@outlook.com

wafubrother@gmail.com

WAFU

WAFU