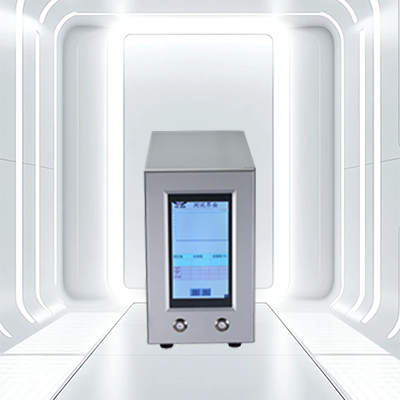

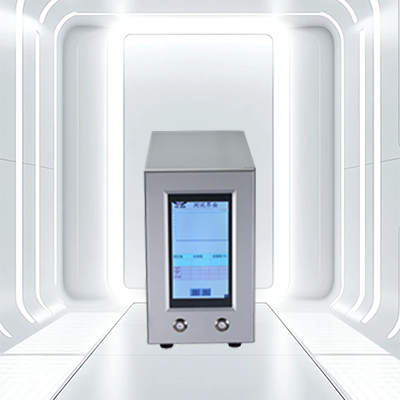

Direct Pressure Leak Tester

High-precision sealing performance testing equipment, providing reliable airtightness solutions for automotive, electronics, medical and other industries.

Actual price depends on product customization

Product Overview

- The fourth-generation airtightness tester uses the direct pressure testing method, mainly for product airtightness testing, IPX waterproof testing, leakage volume detection, etc. This tester is widely used in various industries, including automotive manufacturing, aerospace, electronics, medical devices, and more.

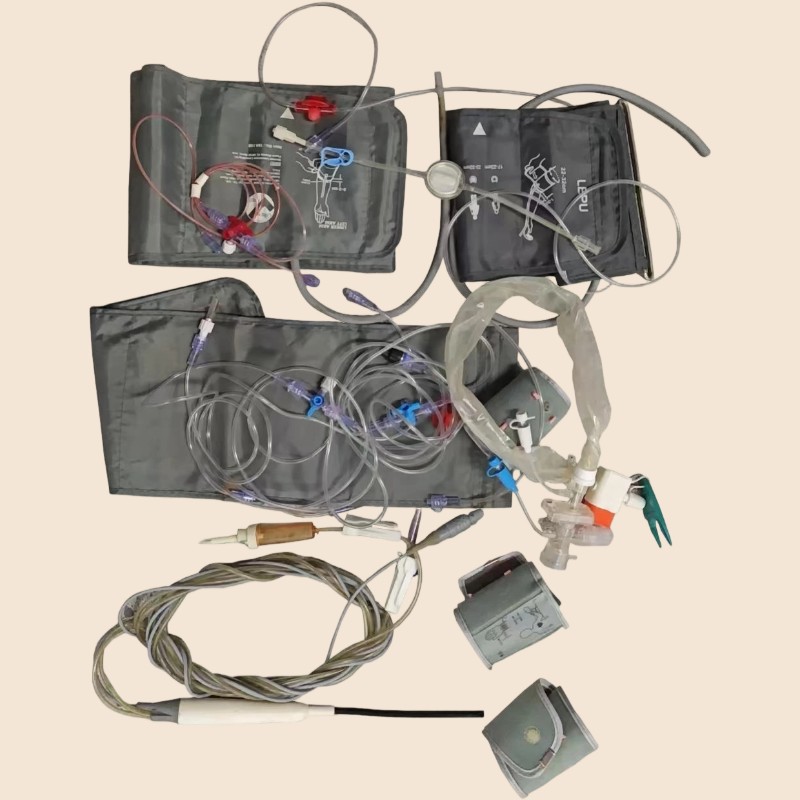

- In the automotive industry, it is used to test the sealing of components such as engines, air conditioning systems, and fuel systems; in aerospace, it ensures the airtightness of aircraft parts to guarantee flight safety; for electronic devices like phones and tablets, it tests the sealing of the casing; in the medical field, it helps in testing the sealing of syringes, airbags, and other products.

Quality Assurance

Our products ensure testing quality and user experience through multiple core features.

Applicable to Various Scenarios

75° Adjustable Viewing Angle

Higher Accuracy

High Sensitivity

Stable Anti-Interference

Customizable

Core Advantages

High Precision Testing

Uses imported high-precision pressure sensors (accuracy ±0.1% F.S) and 24-bit AD acquisition chips, achieving detection sensitivity up to 0.1Pa to ensure accurate and reliable results.

High Testing Speed

Optimized inflation and testing process design combined with a fast-response sensing system, reducing single product testing cycle to under 1 second, improving production efficiency.

Flexible Testing Modes

Supports both positive and negative pressure testing methods, with multiple built-in test programs, customizable test parameters to meet diverse product requirements.

Product Specifications

Product Advantages

| Touch Screen | 7/10 inch touch screen, supports positive/negative pressure tests, open/sealed methods |

| Display Units | Pa, KPa, MPa, Kg, Bar and leakage units |

| Core Performance | Second-generation upgraded product with international high-sensitivity sensor, industry-leading 0.02% accuracy |

| Channel Configuration | 32-channel design, supports quick channel parameter selection and setting |

| Control Capability | Multi I/O control, supports manually adjustable output terminals |

| Testing Modes | Manual/automatic dual modes, supports pressure sequence testing |

| Remote Control | Rich interfaces to connect PLCs, directly drive external devices |

| Intelligent Technology | AI statistical technology, automatically collects pressure/time parameters |

| Sensor | High-precision sensor, auto calibration, 0.001 Pa resolution |

| IoT | Supports remote management and quality traceability, connectable to MES systems |

Technical Specifications

| Number of Channels | 1/2/4 |

| Pressure Type | Positive, Negative, Positive/Negative Pressure |

| Adjustment Mode | Manual/Automatic Adjustment |

| Adjustment Accuracy | ± 0.02%FS ~ ± 0.05%FS |

| Pressure Repeatability | 0.1%FS |

| Adjustment Range | -60 KPa ~ 1 MPa |

| Sensor Range | 0 ~ 50 L/min |

| Sensor Accuracy | ± 1%FS |

| Resolution | 0.001 ml/min ~ 1 ml/min |

Features Introduction

| Touch Screen | 7/10 inch color LCD |

| Operating Interface | WAFU UI |

| Language Support | 6 languages including Chinese, English, Japanese (customizable) |

| Program Sets | 16/99 program groups |

| Alarm Function | Automatic judgment with audible and visual alarms |

| I/O Ports | 4 relay controls (safety fence, solenoid valves, etc.) |

| Communication Interface | RS485 (PLC control/workstation connection) |

| USB Function | Software updates/barcode scanner connection |

| History Records | 100,000 records stored, supports USB export |

Application Scenarios

Contact Us for Customized Solutions

Fill in the form below, and our professional technical team will contact you within 24 hours to provide you with tailored airtightness testing solutions.

Company Address

2nd Floor, Building 6, Sha Yi Environmental Protection Industrial Park, No.496 Chuangcheng Road, Shajing Street, Bao'an District, Shenzhen

Contact Number

+86 17376311087

wafubrother@outlook.com

wafubrother@gmail.com

WAFU

WAFU