Multifunctional Leak Tester

High-precision sealing performance testing equipment providing reliable airtightness solutions for automotive, electronics, medical, and other industries.

Actual price depends on product customization

Product Introduction

- WF 6th Generation Multifunctional Airtightness Tester is an efficient and calibrated multifunctional airtightness testing device developed through 16 years of continuous iteration by Wafu Brothers.

- It includes multiple testing methods and uses precise sensors and advanced detection technology to identify minute gas leakage changes.

- With its advantages of high precision, intelligence, and multi-mode operation, the multifunctional airtightness tester has become an indispensable quality assurance tool in modern production processes.

- Whether detecting tiny airflow leaks or larger gas leaks, the device can promptly and accurately identify them, providing reliable quality control assurance during production.

Quality Assurance

Our products guarantee testing quality and user experience through multiple core features

Suitable for Various Scenarios

75° Adjustable Viewing Angle

Higher Precision

High Sensitivity

Stable Anti-interference

Customized Solutions

Product Details

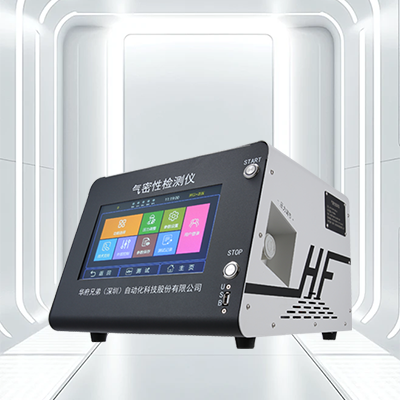

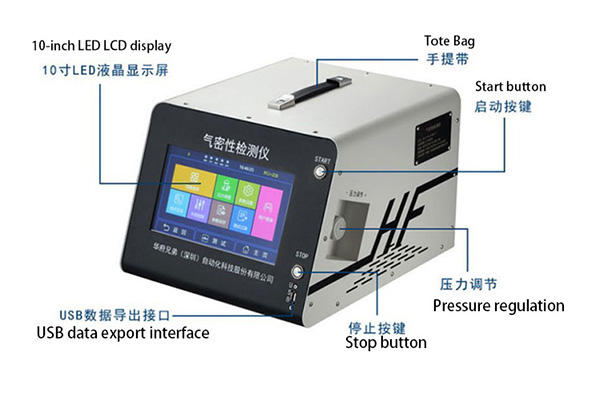

Appearance and Interaction Design

Full Metal Body Design

High-strength aluminum alloy shell with precision machining and surface treatment, strong anti-interference capability, suitable for long-term use in industrial environments.

7-inch HD Touchscreen

Simple and intuitive interface, supports multi-language switching, equipped with auxiliary guidance functions for faster operator learning.

Rich Interface Configuration

Equipped with RJ45, USB, mouse and other communication interfaces, facilitating integration with other equipment to realize automated testing processes.

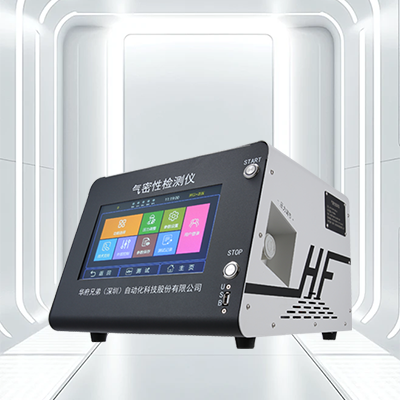

Operating System and UI Pages

Pressure Setting Page

Instrument UI Interface

Testing Technologies and Methods

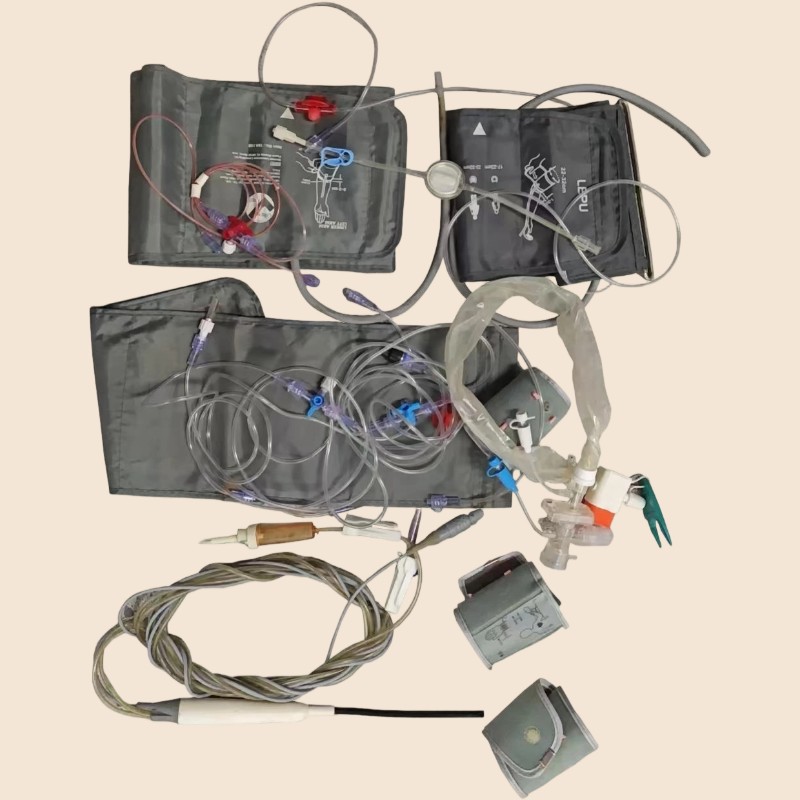

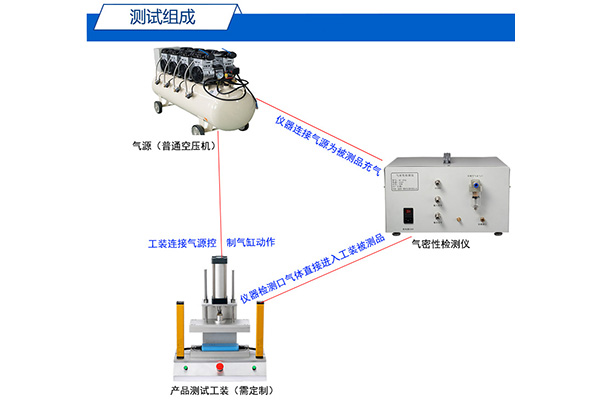

Test Components

Includes air source treatment unit, pressure regulation module, and precision sensors, forming a complete closed-loop detection system.

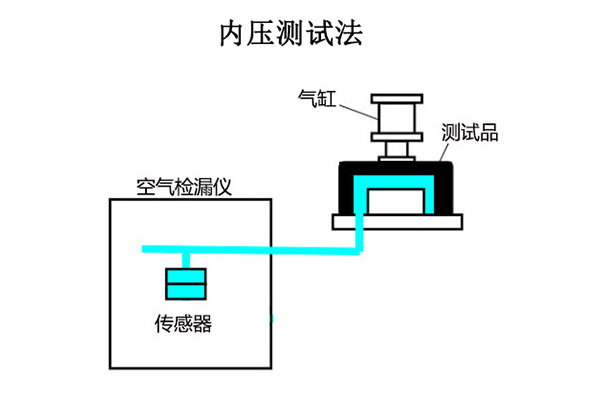

Internal Pressure Test Method

By injecting a specific pressure gas inside the tested workpiece, the pressure variation is detected to assess sealing performance, suitable for enclosed cavity testing.

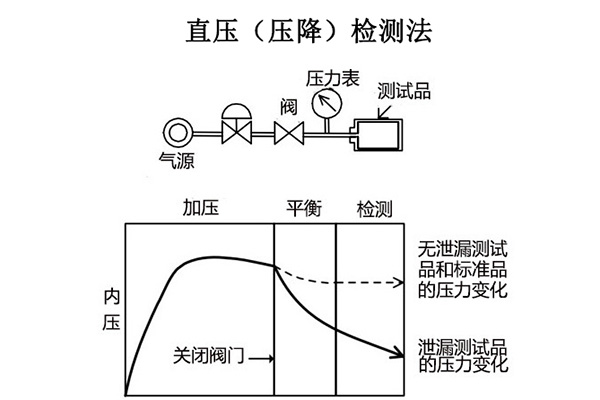

Direct Pressure (Pressure Drop) Test Method

Directly applies test pressure and monitors pressure decay, suitable for production scenarios with high testing speed requirements.

Core Advantages

High-Precision Detection

Uses imported high-precision pressure sensors (accuracy ±0.1% F.S) and 24-bit AD acquisition chips; detection sensitivity can reach 0.1Pa, ensuring accurate and reliable test results.

High Testing Speed

Optimized inflation and testing process design combined with a fast-response sensing system; the testing cycle for a single product can be shortened to under 1 second, improving production efficiency.

Flexible Testing Modes

Supports both positive and negative pressure testing modes; built-in multiple test programs; customizable test parameters based on different product characteristics to meet diverse needs.

Product Specifications

Product Advantages

| Parameter Settings | The device can set testing parameters according to different product requirements, allowing one device to be used for multiple products. |

| Testing Functions | Equipped with one-key automatic testing function; can automatically evaluate pass/fail results (green light for pass, red light and alarm for fail). |

| Signal Input/Output Interfaces | Multiple input and output interfaces including communication ports (connectable to PC, barcode scanners, external control switches), facilitating external control without frequent manual operation. |

| Test Record Storage | Can connect to PC and barcode scanners; test records are automatically saved in folders on the PC for easy data management and quality tracking. |

| Touch Screen | Uses a 7-inch Weizen LCD touch screen; user interface can be customized per client requirements. |

| Core Components | All core components come from professional brands in Japan, Germany, and Taiwan, ensuring accuracy and device stability. |

| Communication Interfaces | Various communication ports: built-in RS232 serial port, RJ45 network port, USB interface, etc. |

| Pressure Range | Multiple options available; pressure range from -95 KPa to 3000 KPa; patented ultra-high-pressure solenoid valve ensures no leakage under ultra-high pressure. |

| Resolution | 24-bit analog-to-digital conversion technology; detection sensitivity up to 0.02 Pa. |

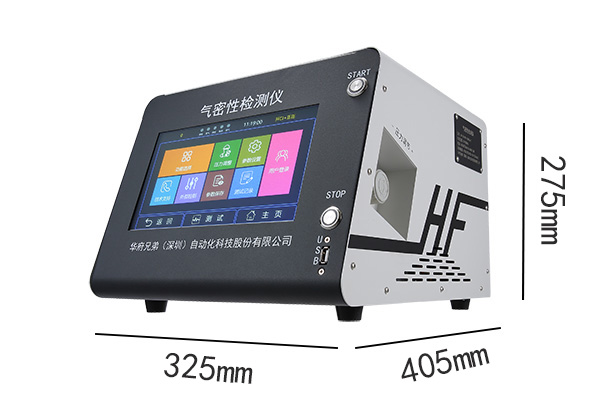

| Basic Parameters | Product size: 405×325×275 mm; Weight: approx. 14 kg; Power supply: AC 110~220V, 50/60Hz. |

Technical Parameters

| Number of Channels | 1/2/4 |

| Pressure Types | Positive pressure, negative pressure, positive & negative pressure |

| Pressure Adjustment Mode | Manual / Automatic adjustment |

| Pressure Adjustment Accuracy | ± 0.05% FS |

| Pressure Repeatability | 0.1% FS |

| Pressure Adjustment Range | -95 KPa – +3000 KPa |

| Sensor Selection Range | -95 KPa – +3000 KPa |

| Sensor Accuracy | 0.1% FS |

| Resolution | 0.1 Pa |

Features

| Touch Screen | 10-inch color LCD |

| User Interface | WAFU UI |

| Languages | Chinese, English, Japanese, German, Spanish, Russian (other languages customizable) |

| Program Count | 16 / 99 programs |

| Judgment / Alarm | Automatic judgment / audible and visual alarms |

| Control I/O Ports | Input/Output, 4 relay control functions (connectable to safety fences, solenoid valves, and red/green warning lights) |

| Serial Communication (RS485) | Receives external PLC control signals; connects to workstations |

| USB | Software updates, barcode scanner |

| Barcode Scanning | Barcode |

| History Records | Stores up to 100,000 test results and can upload to a PC via USB flash drive. |

Application Scenarios

Contact Us for Customized Solutions

Fill out the form below, and our professional technical team will contact you within 24 hours to provide tailor-made airtightness testing solutions.

Company Address

2nd Floor, Building 6, Shayi Environmental Protection Industrial Park, No. 496, Chuangcheng Road, Shajing Street, Bao'an District, Shenzhen

Contact Number

+86 17376311087

wafubrother@outlook.com

wafubrother@gmail.com

WAFU

WAFU