Dual-Channel One-to-Two Leak Tester

A high-precision sealing performance testing device, providing reliable leak testing solutions for industries such as electric vehicles, electronics, and component manufacturing.

The actual price depends on product customization.

Product Overview

- Dual-Channel One-to-Two Leak Tester is a four-station high-precision leak testing system designed for electric vehicle controllers, helping customers efficiently expand testing stations within a limited budget and significantly improve testing throughput.

- The instrument is based on the WAFU Brothers standard leak tester, enabling simultaneous negative-pressure sealing tests on multiple products. It offers a testing accuracy of up to 0.5‰ and delivers results in as fast as 8 seconds, demonstrating outstanding performance within the industry.

- Equipped with an intuitive human–machine interface, testing parameters can be set with one click, ensuring easy operation and reduced training costs.

Quality Assurance

Our products guarantee testing quality and user experience through multiple core features

Wide Applications

75° Adjustable Viewing Angle

Higher Accuracy

High Sensitivity

Stable & Anti-Interference

Customization Available

Product Details

Appearance & Interaction Design

Full Metal Body Design

Crafted with high-strength aluminum alloy, precision machining, and surface treatment. Strong anti-interference capability, ideal for long-term use in industrial environments.

7-inch HD Touchscreen

Simple and intuitive interface with multi-language support and built-in guidance functions, making it easier for operators to get started quickly.

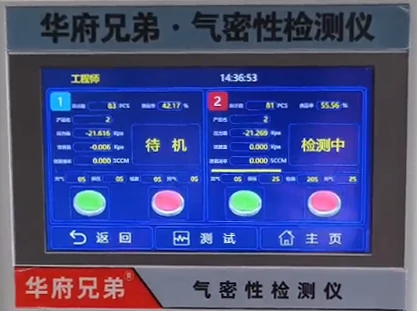

Operating System & UI Pages

Pressure Setting Page

Instrument UI

Testing Technologies & Methods

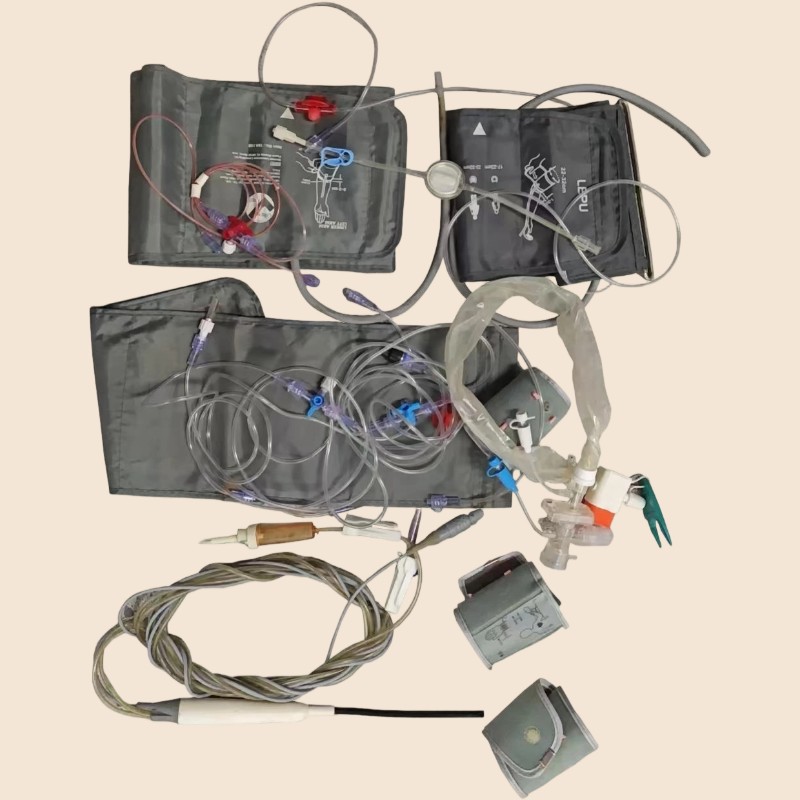

Test Components

Includes air source processing unit, pressure regulation module, and precision sensors to form a complete closed-loop testing system.

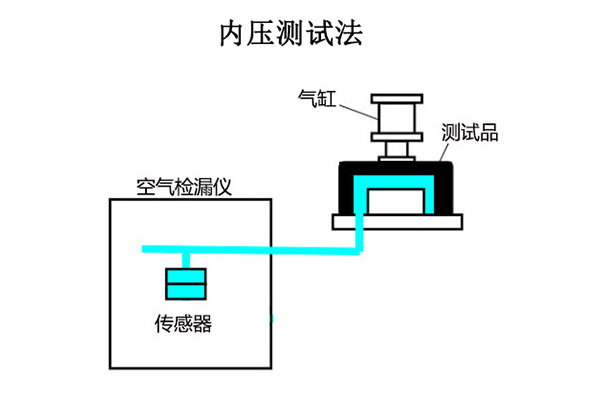

Internal Pressure Test

Applies specific pressure gas into the tested part and monitors pressure changes to determine sealing performance. Suitable for closed cavity detection.

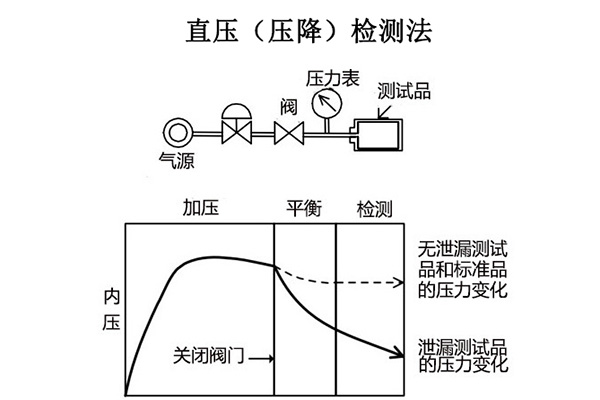

Direct Pressure (Decay) Test

Directly applies test pressure and monitors pressure decay. Suitable for production scenarios requiring high testing speed.

Core Advantages

High-Precision Testing

Equipped with imported high-precision pressure sensors (accuracy ±0.1% F.S.) and a 24-bit AD acquisition chip. Detection sensitivity reaches 0.1 Pa, ensuring accurate and reliable test results.

High-Speed Testing

Optimized inflation and testing process, combined with a fast-response sensor system. The testing cycle for a single product can be reduced to less than 1 second, greatly boosting production efficiency.

Flexible Testing Modes

Supports both positive and negative pressure testing methods. Built-in multiple test programs allow custom parameter settings according to product characteristics, meeting diverse application needs.

WAFU

WAFU