How Leak Testing Builds a Solid Reliability Defense for Electronics

1. Why Leak Testing is the "Lifesaver" for Electronic Products?

The core components of electronic products—precision circuits, microchips, and high-integration modules—are the "delicate heart" of devices. Once liquids (water, oil mist), gases (humidity), or particles (dust) breach the sealing barrier, the consequences range from short circuits and performance degradation to complete device failure.

Leak protection is critical in scenarios such as:

- Consumer Electronics: Devices like smartphones and wireless earbuds require IP67/IP68 certification (IP67 for short-term submersion, IP68 for long-term underwater operation). Without it, sweat or rain can become "killers".

- Outdoor Equipment: Action cameras and field sensors must withstand sandstorms and heavy rain. Seal failure can cause devices to "shut down" in harsh environments.

- Medical Electronics: Devices like glucose meters and implants must be perfectly sealed to prevent body fluids from contaminating or interfering with measurements.

- New Energy Vehicle Electronics: If onboard battery management systems or high-voltage connectors get wet, it may lead to leakage currents or even fires.

Pre-shipment leak testing is the final safeguard against these risks—ensuring product quality and reducing after-sales maintenance costs by over 40%.

2. The "Technical Secrets" of Leak Testing

Currently, mainstream leak detection methods fall into four categories, each suited to different applications:

| Method | Principle | Advantages | Applications |

|---|---|---|---|

| Differential Pressure Method | Pressurize or vacuum and monitor pressure changes | High precision (±0.1Pa), non-destructive | Phones, automotive electronics, medium to large parts |

| Flow Method | Continuous air supply with flow sensor monitoring | Real-time detection, suitable for large leaks | Outdoor device housings, large modules |

| Micro Pressure Method | Capture tiny leaks under ultra-low pressure (≤10Pa) | Extremely sensitive (can detect 0.01cc/min) | Earbuds, sensors, miniature components |

| Traditional Water Submersion | Submerge in water and observe bubbles | Low cost | Being phased out (inefficient, risk of secondary damage) |

Among these, the differential pressure and micro-pressure methods are the industry's top choices for electronics due to their "speed + precision"—some tests take as little as 2 seconds without damaging components.

3. Four Key Parameters You Must Watch During Testing

The reliability of leak testing results depends on careful control of these factors:

- Test Pressure: Must match product design limits. For example, earbud cavities typically withstand ≤50kPa; overpressure can deform the shell.

- Allowable Leak Rate: Different IP ratings have specific standards. IP67 allows ≤0.3cc/min (about 150L/year), IP68 requires ≤0.1cc/min.

- Test Duration: Includes pressurization (stabilization), holding (eliminating interference), and detection. Small products (like earbuds) take 3–5 seconds, large modules 10–15 seconds.

- Fixture Design: Often overlooked but crucial. For curved phone backs or irregular sensors, customized silicone seals and positioning fixtures are needed to prevent false readings (accuracy within ±0.5%).

4. From Testing to Reliability: A Practical Path Forward

Leak testing is not just a "final check"—it’s a quality assurance process throughout the product lifecycle:

- Design Stage: Validate sealing structures (e.g., silicone ring compression, ultrasonic welding strength) to eliminate potential failure points early.

- Production Stage: 100% inspection ensures consistency. For example, a smartphone factory reduced defect rates from 3% to 0.1% with automated testing.

- After-Sales Stage: Traceable data helps quickly determine if failures are due to process issues or transportation damage.

- Brand Value: Consistent sealing performance improves user reputation. A sports earphone brand increased repurchase rates by 25% after achieving IPX7 certification.

5. Case Study: How Bluetooth Earbuds Achieve "Leak-Free" Reliability

Bluetooth earbuds are small (cavity volume often ≤5cm³) and face complex environments (sweat, rain). A leading brand implemented this solution:

Testing Solution

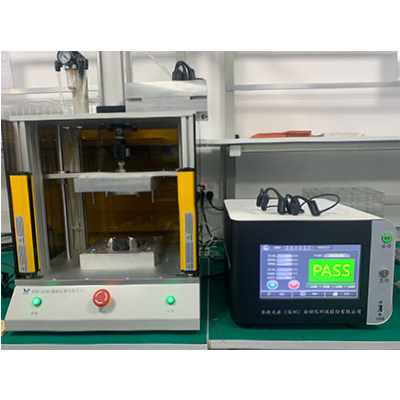

Uses a fully automated micro-pressure leak tester with custom fixtures tailored to the earbud’s contours:

- Pressurize the earbud cavity to 30kPa (equivalent to 3 meters underwater);

- Hold pressure for 2 seconds, monitor pressure change for 1 second (allowable drop ≤0.5Pa);

- Real-time data upload to MES system; unqualified products are automatically flagged and rejected.

Figure 1: Automated Leak Test Equipment

Figure 2: Bluetooth Earbud Housing

Video: Automated Leak Testing for Bluetooth Earbuds

Test Results

- Waterproof-related after-sales complaints dropped from over 200 per month to fewer than 30—a reduction of over 85%.

- Successfully passed IPX4 certification (protection against water splashes from any direction), expanding outdoor usage scenarios.

- Test efficiency reached 1,200 units per hour, matching the production line’s pace (traditional manual testing only reached 300 units/hour).

This case shows that leak testing is not just a quality control tool—it’s a hidden driver of product competitiveness.

6. Future Trends: From "Detection" to "Intelligent Early Warning"

As electronic devices become more compact and integrated, leak testing is evolving to be smarter:

- AI-Assisted Leak Detection: Algorithms analyze test data to improve false positive/negative identification.

- MES Integration: Automatically records results for traceability and production management.

- Multi-Channel/Parallel Testing: Greatly enhances production throughput for mass manufacturing.

- Micro Leak Detection: Meets the demands of wearable and miniature device testing.

Conclusion

For electronic products where performance and stability are key competitive factors, leak testing is not just a quality check—it’s a technical safeguard for brand reputation and product reliability. As consumer demand for waterproof and dustproof capabilities grows, leak testing equipment will play an increasingly vital role in the electronics manufacturing industry.

WAFU

WAFU