All-Scenario Airtightness Testing Solution — Safeguarding Final Quality Inspection

In modern manufacturing, final inspection is not only the last checkpoint for quality control but also the lifeline of brand reputation. As industrial processing technology continuously advances, product leaks have become increasingly minute, making traditional testing methods insufficient to fully safeguard this defense line. Leveraging years of technical expertise, WAFU Brothers has launched an all-scenario airtightness testing solution to help manufacturers firmly uphold the “zero leakage” baseline before products leave the factory.

1. Why Is Product Seal Testing So Important?

Whether it’s electronic devices, automotive parts, medical instruments, or household appliances, leakage issues can cause safety hazards and economic losses:

- Performance degradation: Reduced waterproof rating, affecting product lifespan

- Safety risks: Leakage in gas valves or pressure vessels may lead to accidents

- Customer complaints: Increased after-sales costs and damage to brand image

Airtightness testing can detect tiny leaks before product delivery, preventing issues from reaching the market at the source.

2. Industry Pain Points of Using Water Testing Methods

In the past, most companies chose water testing methods (such as immersion tests and spray tests) to verify product sealing. Although intuitive, these methods have obvious drawbacks:

- 1. With industrial process innovations, many tiny leaks are difficult to detect.

- 2. Long testing times, unsuitable for mass production.

- 3. Strong environmental dependence; water temperature and pressure affect testing results.

- 4. Destructive testing; once the product gets water inside, repair costs are high.

These pain points put companies in a dilemma between quality control and cost.

3. Using the All-Scenario Airtightness Testing Solution

With 16 years of deep industry experience, WAFU Brothers has addressed many common testing pain points by proposing an all-scenario gas testing solution, focusing on technology, intelligence, and service to build a comprehensive, multi-layered “zero leakage” protection system for manufacturing.

1. Multi-Technology Integration: Building a Robust Barrier of Non-Destructive and High-Precision Testing

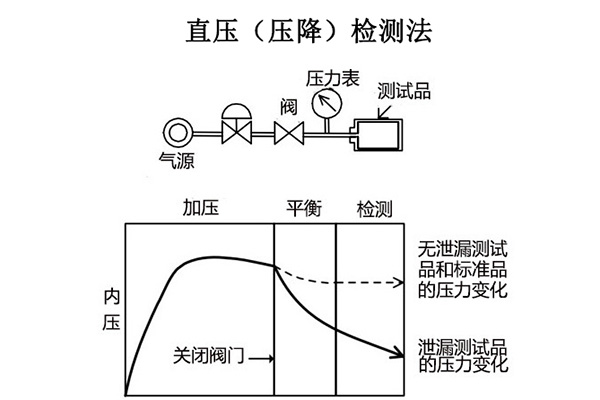

We integrate advanced testing technologies such as positive pressure decay, vacuum decay, differential pressure comparison, and helium mass spectrometry leak detection. For large-volume, high-pressure scenarios like automotive engine blocks and high-pressure gas tanks, devices using the positive pressure decay method act as "scouts" using high-pressure gas to precisely monitor pressure decay and quickly locate millimeter-level leaks. In fields extremely sensitive to micro leaks, such as medical devices and semiconductor chips, helium mass spectrometry devices, with their picogram-level detection sensitivity, act like an "electron microscope," leaving no tiny hidden risks overlooked. Differential pressure comparison and vacuum decay methods excel in high-efficiency batch testing of consumer electronics and household appliances by analyzing pressure changes under vacuum or comparing with standard parts to achieve rapid and precise detection. These technologies work together to form a comprehensive testing matrix covering all industries and scenarios. All testing processes are non-destructive, avoiding secondary damage to products, and comply with ASTM E498-20 "Standard for Nondestructive Testing."

2. Temperature Compensation and Intelligent Noise Reduction System

WAFU Brothers integrates cutting-edge technologies such as artificial intelligence, IoT, and big data into airtightness testing equipment to tackle the impacts of ambient temperature and noise on testing results. Through continuous learning and training, WAFU Brothers’ airtightness testers have greatly achieved precise temperature compensation and noise recognition/elimination, improving testing efficiency by over 60%, and easily integrating with enterprise automation production lines!

4. Real-World Application Results

1. Automotive Engine Hood Seal Testing

Audi introduced WAFU Brothers’ airtightness testers to conduct comprehensive inspections on core components such as engine hoods, fuel lines, and transmissions. This successfully identified and resolved previously hard-to-detect micro leaks smaller than 0.1 mm². As a result, product rework costs were reduced by 8 million RMB, and market failure rates dropped by 65%, effectively ensuring the safety and reliability of the vehicle’s powertrain and strengthening the brand’s industry leadership.

2. New Energy Charging Gun Seal Testing

Renowned automakers such as FAW Audi and GAC Group have adopted WAFU Brothers’ airtightness testers and the all-scenario airtightness testing solution, perfectly integrating with automotive manufacturing assembly lines and significantly improving production efficiency.

3. Consumer Electronics Product Testing

WAFU Brothers customized an automated sealing testing solution for a smartphone manufacturer, integrating differential pressure comparison devices with the automated production line. The waterproof test time per phone was reduced to 6 seconds, with a daily testing capacity of up to 30,000 units, and the detection accuracy remained stable and reliable. The company not only met the market’s high standards for waterproof and dustproof performance but also greatly improved production efficiency, reducing product complaint rates by 70%, standing out in the fierce market competition.

5. Future Outlook: Continuously Strengthening the “Zero Leakage” Technology Defense

In the future, WAFU Brothers will continue to increase R&D investment. Technologically, it will develop high-safety testing technologies suitable for new energy vehicle battery packs and hydrogen storage equipment. In terms of intelligence, it will develop intelligent testing devices with autonomous learning and self-optimization capabilities.

WAFU

WAFU