Learn the Working Principle of Airtightness Testers in Seconds through a Smartphone Airtightness Testing Example

1. Explanation of the Working Principle of Airtightness Testers

What is the principle of an airtightness tester? Most people can probably guess from its name that it has something to do with "air leakage," but few know how it can determine a product’s sealing performance within just a few seconds. In fact, the airtightness tester is not some unattainable technology. Today, I’ll use several smartphone airtightness testing cases to explain how the tester works!

During the manufacturing process of smartphones, airtightness testing is an indispensable step. In daily use, we often encounter situations such as getting wet in the rain, being soaked in sweat during exercise, or accidentally dropping the phone in water. If the sealing is poor, minor issues such as screen fogging or button failure may occur, while in more serious cases, it can lead to circuit short circuits or even complete device failure.

Therefore, smartphone manufacturers must strictly perform airtightness tests on the entire device and its key components. Common testing locations include the SIM card tray, headphone jack, speaker, USB port, button gaps, and back cover adhesive areas. These spots are often the weakest points where leakage is most likely to occur. Only through systematic airtightness testing before shipment can smartphones meet IP67/IP68 waterproof and dustproof standards, providing users with a safer and more reliable experience.

So how does the WAFU Brothers airtightness tester check the above critical leakage areas? Typically, our testers use three main testing principles: positive pressure method, differential pressure method, and flow method. These principles are actually quite straightforward, explained as follows:

- Positive Pressure Method: Compressed air is introduced into the tested product (e.g., smartphone cavity) to create a pressure difference between the inside and outside. After closing the air source and holding for a period, if the product is well-sealed, the pressure remains nearly constant. If there is a leak, the internal pressure will gradually decrease.

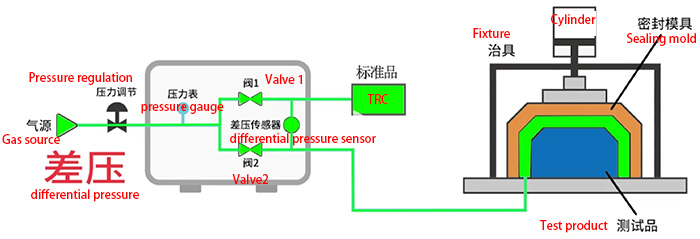

- Differential Pressure Method: The tested product and a reference chamber are simultaneously filled with air at the same pressure, and then the pressure difference between the two is monitored. If the tested product leaks, its internal pressure will drop, creating a difference compared to the standard chamber. A high-precision differential pressure sensor can detect this change.

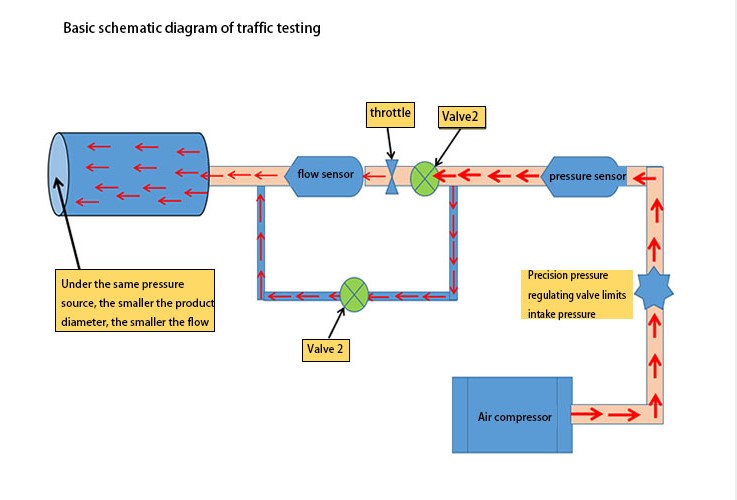

- Flow Method: A flow meter directly measures the gas leakage rate between the product cavity and the atmosphere. If the product has a leak, gas will continuously flow out, and the flow meter will display the real-time flow rate, from which the leakage rate can be determined.

2. Analysis of Smartphone Shell Testing Case

From the above, we now have a general understanding of the principle of airtightness testing. Let’s further explore how our airtightness tester works through several real-world cases, such as the airtightness testing of a smartphone shell: 《《Go to YouTube to Watch》》

From the above explanation and video case, we can see that whether it is the rapid screening of the positive pressure method, the high-precision comparison of the differential pressure method, or the direct quantitative measurement of the flow method, an airtightness tester can complete a test within just a few seconds. Each method has its own focus, but the core goal remains the same—to ensure that the product’s airtightness meets the required standard.

3. Advantages Summary

From a long-term perspective, airtightness testing is not only the "gatekeeper" of the quality inspection process, but also a safeguard for modern manufacturing enterprises to enhance brand credibility and reduce after-sales risks. WAFU Brothers will continue to innovate, striving to surpass overseas competitors and become the leading domestic supplier and solution provider in the airtightness tester industry—bringing honor to our country!

WAFU

WAFU