How to Choose an Airtightness Tester? Detailed Explanation of WAFU Brothers Direct Pressure / Differential Pressure / Flow Type Equipment Testing Principles and Methods

In industrial manufacturing, airtightness testing is a critical step to ensure product quality, and choosing the right airtightness tester is of utmost importance. WAFU Brothers, a well-known company in the industry, offers direct pressure, differential pressure, and flow type airtightness testers, each with unique features to meet different testing needs. This article provides an in-depth analysis of the testing principles and methods of these three types of equipment to help enterprises make precise selections.

Direct Pressure Airtightness Tester

The direct pressure airtightness tester is a basic model launched by WAFU Brothers, featuring a relatively straightforward testing principle. Simply put, it involves injecting gas under a certain pressure into the tested workpiece, then closing the inflation valve. A high-precision pressure sensor continuously monitors the internal pressure of the workpiece. If there is leakage, the internal pressure will gradually decrease over time, and the device judges the sealing quality based on the degree and speed of the pressure drop.

This testing method offers the advantages of simple operation and fast testing speed. For example, in testing mobile phone shells, once the shell is fixed, the WAFU Brothers direct pressure airtightness tester automatically completes the inflation, pressure holding, and testing process, usually within 10–30 seconds, making it very suitable for high-volume production scenarios. Moreover, the equipment cost is relatively low, making it a cost-effective choice for products with less stringent precision requirements, such as ordinary plastic containers and low-pressure pipelines.

However, the direct pressure tester has limitations. Its results can be affected by factors such as ambient temperature and workpiece volume, resulting in limited precision. Generally, it can detect leak points with a leakage rate above 1×10⁻³ Pa·m³/s. Therefore, for products requiring extremely high sealing performance, such as high-precision medical device components, the direct pressure tester may not meet the demands.

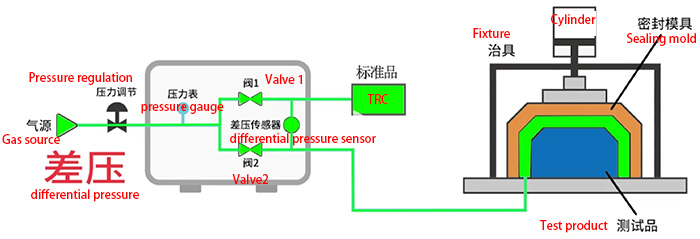

Differential Pressure Airtightness Tester

The differential pressure airtightness tester is an upgraded product developed by WAFU Brothers based on the direct pressure tester, featuring more precise testing principles. It introduces a reference standard workpiece with the same structure as the tested workpiece and known to be perfectly sealed. Both the standard and tested workpieces are simultaneously filled with gas at the same pressure. After stabilization, a differential pressure sensor measures the pressure difference between them. If the tested workpiece leaks, the pressure difference will gradually increase, allowing the device to accurately determine the leakage amount based on the pressure difference changes.

This method’s outstanding advantage is its high accuracy, capable of detecting micro-leaks with leakage rates as low as 1×10⁻⁵ Pa·m³/s. It is ideal for products with strict sealing requirements, such as automotive engine fuel lines and radiators. After adopting WAFU Brothers’ differential pressure tester, a car parts manufacturer improved their sealing pass rate from 92% to 99.5%, greatly reducing after-sales failures caused by sealing issues.

However, the differential pressure tester requires high consistency of the standard parts; different workpiece models need corresponding standard parts, and the standard parts must be adjusted when changing the tested workpiece. This makes the operation somewhat more complicated, and the equipment cost is higher than the direct pressure type. For related cases, see the Automotive Parts Sealing Testing Case.

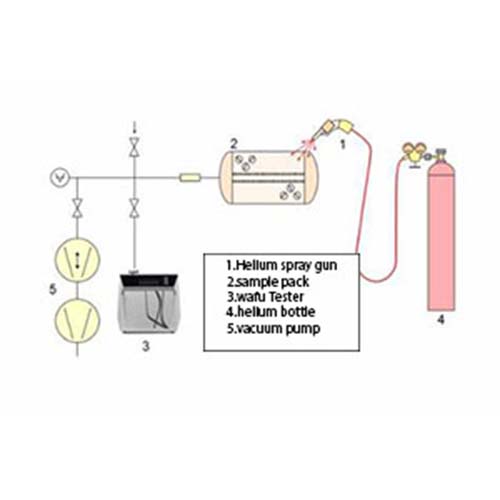

Flow Type Airtightness Tester

The flow type airtightness tester is a professional device developed by WAFU Brothers for scenarios that require precise quantification of leakage. Its testing principle is to maintain a constant internal pressure in the tested workpiece by injecting gas, while a mass flow sensor continuously monitors the amount of gas added to keep the pressure stable. This supplementary flow rate corresponds to the actual leakage rate of the workpiece.

This method can directly output precise leakage values, not just pass/fail judgments, with testing accuracy up to 1×10⁻⁶ Pa·m³/s. It is widely used in fields with strict numerical leakage requirements. For example, in the medical device industry, the sealing performance of infusion sets and anesthesia machines directly affects patient safety and must be strictly controlled. WAFU Brothers’ flow type tester precisely meets these requirements, ensuring leakage rates comply with the ISO 80369 medical device sealing standards.

However, the flow type tester requires a highly stable gas source, equipped with high-precision pressure regulation devices. The purchase and maintenance costs are relatively high, making it more suitable for enterprises with strict quantitative testing requirements. For equipment configuration details, visit the Flow Type Tester Technical Specification Page.

Applicable Scenarios and Selection Recommendations for the Three Types of Equipment

When selecting equipment, enterprises need to consider multiple factors such as product characteristics, required testing accuracy, production efficiency, and budget.

| Equipment Type | Testing Accuracy (Pa·m³/s) | Testing Speed | Applicable Products | Core Advantages |

|---|---|---|---|---|

| Direct Pressure | ≥1×10⁻³ | 10-30 seconds/item | Mobile phone shells, plastic containers, low-pressure pipelines | Simple operation, low cost, high efficiency |

| Differential Pressure | ≥1×10⁻⁵ | 20-40 seconds/item | Automotive fuel lines, radiators, outdoor lighting | High accuracy, strong anti-interference capability |

| Flow Type | ≥1×10⁻⁶ | 30-60 seconds/item | Infusion sets, anesthesia machines, aerospace components | Quantifiable leakage, precise data |

If the products are mobile phone shells, ordinary plastic containers, or other products with low sealing precision requirements and large batch sizes, WAFU Brothers’ direct pressure airtightness tester is a good choice, meeting basic quality control and high production efficiency.

For automotive fuel lines, radiators, and other parts with higher sealing requirements, the differential pressure tester is more suitable as it can accurately detect tiny leaks and effectively prevent safety risks caused by sealing issues.

For medical device manufacturers, due to strict quantitative leakage standards, the flow type airtightness tester is the ideal choice, providing precise data support for product quality.

Additionally, enterprises should consider the impact of the production environment. If the workshop temperature and humidity fluctuate significantly, it is recommended to choose WAFU Brothers equipment with environmental compensation functions (such as the differential pressure DPS-8000 series or flow type FMS-9000 series) to ensure accuracy. Meanwhile, cost budget should also be taken into account to select the most cost-effective equipment that meets the testing requirements.

In summary, WAFU Brothers’ direct pressure, differential pressure, and flow type airtightness testers each have their advantages. Enterprises should fully understand their own needs and combine equipment features to select the most suitable testing equipment, safeguarding product quality. For customized selection advice, click Online Consultation to get professional help.

WAFU

WAFU