Bluetooth Earbuds Airtightness Testing Solution

1. Why Is Airtightness Testing Necessary for Bluetooth Earbuds?

Bluetooth earbuds have a compact structure that integrates batteries, speakers, microphones, circuit boards, and other precision components. They are often exposed to sweat, rain, and humidity during daily use. Poor sealing can lead to short circuits, corrosion, sound distortion, or even safety hazards if moisture reaches the battery. Therefore, waterproof airtightness testing is a critical step to ensure product reliability and user experience.

Figure 1: Bluetooth Earbud Structural Diagram

Figure 1: Bluetooth Earbud Structural Diagram

2. Testing Method and Principle

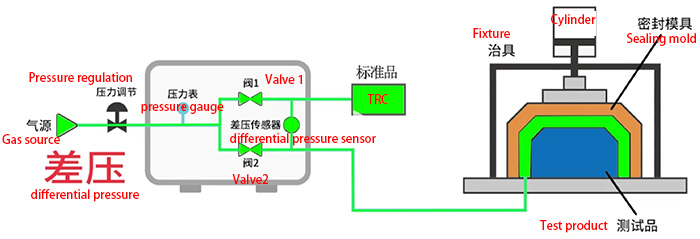

The mainstream method is the differential pressure method. It involves pressurizing the inner cavity of the earbud and sealing the system, then monitoring pressure changes with a sensor. If a leak exists, the pressure will drop. Compared with water immersion testing, this method offers higher efficiency, non-destructiveness, and automation advantages.

- Supports protection levels such as IPX4 to IPX7

- Non-contact testing, does not damage the product

- Can be integrated into automated production lines for 100% inspection

Figure 2: Principle of Differential Pressure Airtightness

Testing

Figure 2: Principle of Differential Pressure Airtightness

Testing

3. Testing Equipment and Fixture Design

Figure 3: Bluetooth Earbud Airtightness Testing Device

Figure 3: Bluetooth Earbud Airtightness Testing Device

The testing device is a benchtop airtightness tester, featuring rapid inflation, pressure stabilization, pressure sensing, result determination, and data logging. It works with customized flexible sealing fixtures to ensure no air leakage and no damage to the earbud casing during testing.

- Optional single-station or dual-station models

- MES system interface support

- 0.1 kPa-level sensitivity

4. Video Demonstration of the Testing Process

Video: Fully Automated Airtightness Testing Process for Bluetooth Earbuds

5. Standard Testing Procedure

- Place the earbud into the fixture and start the test program

- The system automatically inflates to the set pressure (e.g., 50 kPa)

- Stabilize pressure for 0.5–1 second and sample the leak value

- Compare with threshold to determine OK / NG

- Record test data; if NG, sound and light alarm is triggered

6. Recommended Parameter Configuration

| Parameter | Recommended Value | Description |

|---|---|---|

| Test Pressure | 50 kPa | Adjustable based on product pressure tolerance |

| Pressure Stabilization Time | 0.8 seconds | Start detection after stabilization |

| Testing Time | 1.5 seconds | Detect pressure decay |

| Leakage Standard | < 0.2 kPa | Equivalent to 0.3 cc/min in flow rate |

| Test Cycle | 3–4 seconds/item | Compatible with production line pace |

7. Conclusion

As consumer expectations for waterproof performance continue to rise, airtightness testing has become a standard requirement for Bluetooth earbuds. Implementing standardized differential pressure testing systems not only improves product yield and reduces after-sales issues, but also helps brands obtain IP certifications and enhance competitiveness.

WAFU

WAFU