Customers Were Amazed: How Can the Automotive Oil Separator Leak Tester Be This Accurate?

1. Product Overview

The automotive oil separator, also known as an oil distribution module or lubrication circuit distributor, is a key component in an engine or transmission lubrication system. Its main function is to precisely distribute oil from the main oil circuit to various lubrication points (such as the crankshaft, camshaft, hydraulic tappets, and turbo bearings), ensuring that the entire power system receives stable lubrication and cooling under different working conditions. It not only affects the efficient use of engine oil but also directly impacts engine lifespan, performance, and energy efficiency.

Fig.1: Concept diagram of an automotive oil separator

Fig.1: Concept diagram of an automotive oil separator

2. Why Perform Leak Testing on the Transmission Housing?

The oil separator usually distributes engine or transmission oil to different components (crankshaft, camshaft, hydraulic tappets, turbocharger, cooling module, etc.). Since there are multiple independent oil passages inside the separator, even a tiny leak can cause a drop in oil pressure, insufficient lubrication, and in severe cases, metal friction, overheating, or seizure. Additionally, the separator is made of plastic, which is prone to injection shrinkage and material batch variations. Therefore, leak testing must be performed before shipment to ensure the product meets quality standards.

3. Basic Solution Concept

Project Challenges:

The oil separator has multiple oil chambers that must each be individually sealed, which requires extremely tight fixture sealing. Most of its oil ports are quick-connect or O-ring types, meaning the clamping pressure during downward sealing must be sufficient but not deform the connector. If the fixture’s sealing is inadequate, local air leakage can occur, leading to false leakage results.

Client Requirements and Solution Design:

For this project, WaFu Brothers engineers designed a dedicated fixture according to the separator’s structure. After understanding the client’s needs, we learned that because the separator’s production cost is high, defective products are not discarded — the leakage point must be located for rework. Therefore, WaFu Brothers recommended a water immersion testing method, which makes it easier to visually identify small leaks on the housing surface.

Testing Process:

- 1. Place the oil separator in the dedicated fixture and press the start button — the upper clamping mechanism automatically descends to achieve sealing.

- 2. The testing platform automatically lowers to the designated water level in the tank.

- 3. The testing system injects air according to the set program. The operator visually observes for air bubbles in the water. If bubbles appear, the product fails the leak test, and the leak point can be quickly located based on the bubble position.

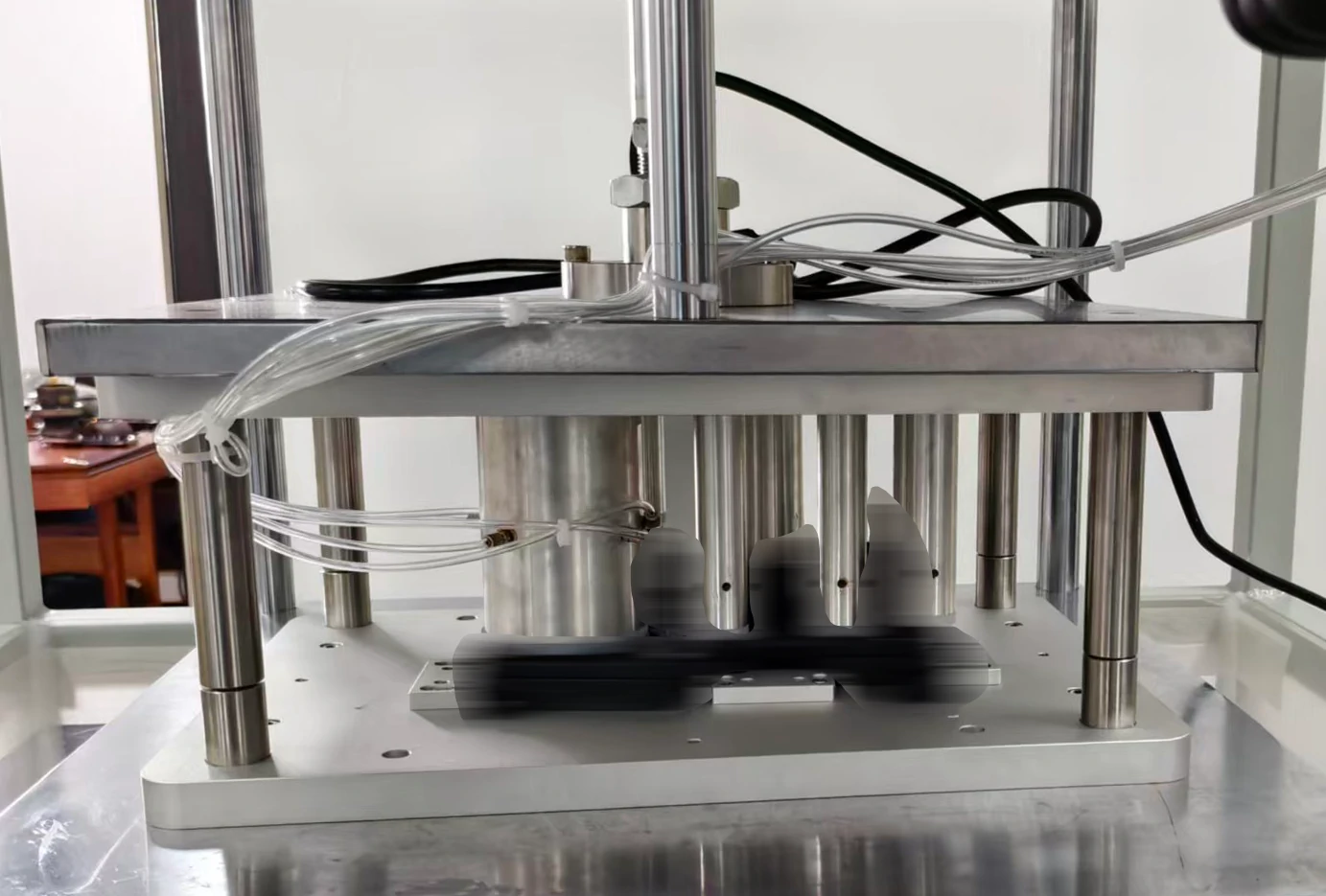

Fig.2: Upper clamping mechanism securing the automotive oil separator

Fig.2: Upper clamping mechanism securing the automotive oil separator

4. WaFu Brothers’ Advantages

In all leak testing processes, the sensor plays a crucial role as it directly affects measurement accuracy. With 16 years of experience in the leak testing industry, WaFu Brothers deeply understands its importance in overall testing performance. Therefore, all sensors in our testing equipment are custom-made by reputable suppliers according to technical requirements, not off-the-shelf products. This ensures consistently high sensitivity and reliable test accuracy.

WaFu Brothers believes that quality lies in the details — only through meticulous craftsmanship in every step can we create high-quality leak testing equipment. Clients can have complete confidence in our attention to detail; WaFu Brothers always puts quality first. Our after-sales service period also exceeds the industry standard.

5. Customized Machine Display

Based on the client’s testing requirements and production line setup, the standard leak tester was too compact to meet the operational needs. Therefore, WaFu Brothers engineers proposed using a custom non-standard leak and water testing system. Figure 3 shows the final equipment delivered to the client.

Fig.3: Final equipment delivered to the client

Fig.3: Final equipment delivered to the client

6. Conclusion

Through the design of this automotive oil separator leak testing solution, WaFu Brothers has further expanded its expertise in automotive component leak detection. We look forward to collaborating with more partners in related industries to improve product sealing performance and achieve mutual growth and success.

WAFU

WAFU