The Truth No One Told You: This Transmission Housing Leak Test Case Reveals Industry Risks!

1. Product Overview

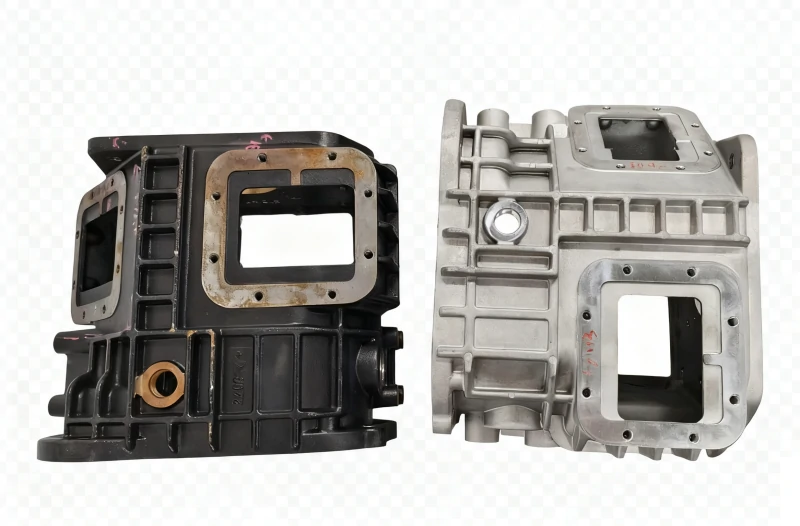

In an automobile’s powertrain system, the transmission is one of the most critical components, second only to the engine. It ensures efficient power delivery from the engine to the wheels. As the structural core of the transmission, the transmission housing plays a key role in support, sealing, and protection. Its machining precision and leak directly affect the vehicle’s driving performance, quality, and lifespan—making it essential for ensuring smoothness and reliable power transmission.

2. Why Test the Leak of the Transmission Housing?

A certain auto parts manufacturer produced a batch of transmission housings that appeared flawless—perfect dimensions, smooth assembly, and no visible defects. However, once installed, vehicles began exhibiting slight transmission noise. Initially suspected to be an assembly issue, further investigation revealed that the problem stemmed from tiny leaks in the transmission housing itself, leading to internal component issues. Such subtle defects are often undetectable with traditional inspection methods.

Modern vehicles place increasingly high demands on transmission housing manufacturing quality. Whether for traditional fuel cars, hybrid models, or emerging new energy vehicles, the lightweight design, structural precision, and guaranteed leak of the transmission housing are key indicators of both transmission and overall vehicle quality. Therefore, high-precision leak testing of transmission housings is a crucial step in ensuring component reliability and vehicle safety.

Fig. 1: Transmission housing provided by the client for testing

Fig. 1: Transmission housing provided by the client for testing

3. Basic Solution Concept

Project Challenges:

The transmission housing is relatively large and structurally complex, which increases the likelihood of micro-leaks forming during machining or assembly. Traditional leak testers often fail to detect such small leaks. Ensuring uniform pressurization and accurate measurement under fully sealed conditions places high demands on fixture sealing design, pneumatic circuit responsiveness, and sensor precision.

Client Requirements & Solution Design:

Considering the testing challenges and the client’s production process, WaFu Brothers engineers designed a comprehensive leak testing solution. To detect even the smallest leaks while allowing clients to visually locate leak points and rework defective products, the engineers recommended a submersion-based leak detection approach.

Testing Process:

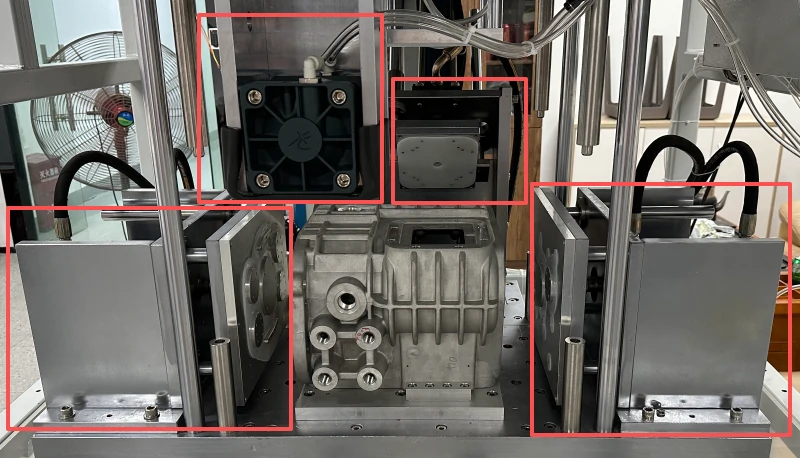

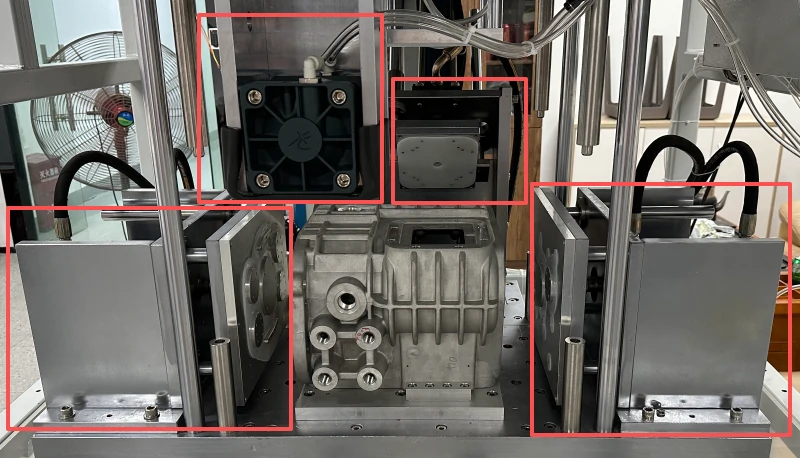

- 1. Place the transmission housing correctly into the fixture. Once the start button is pressed, the multi-directional clamping system engages to securely seal the product, as shown in Fig. 2:

Fig. 2: Multi-directional clamping mechanism

Fig. 2: Multi-directional clamping mechanism

- 2. The machine automatically lowers the fixture platform into the pre-set water level.

- 3. The system injects air through the designed inlet ports. Operators can then visually inspect for bubbles in the water to identify whether leaks are present and pinpoint their exact locations.

Fig. 2: Multi-directional clamping mechanism

Fig. 2: Multi-directional clamping mechanism

4. WaFu Brothers Advantages

In leak testing, the quality of the sealing ring is crucial for achieving accurate and reliable results. WaFu Brothers fully understands this, which is why all sealing rings used in our leak testers are self-developed and produced in-house—not purchased externally. Each seal is custom-designed according to the client’s product structure to ensure precise sealing during every test cycle.

Fig. 3: Custom sealing ring used in this project

Fig. 3: Custom sealing ring used in this project

Each sealing ring undergoes over one million life cycle tests and multi-condition verifications. Different product types are matched with specific seal materials and specifications to ensure long-term stability and accuracy throughout the testing process.

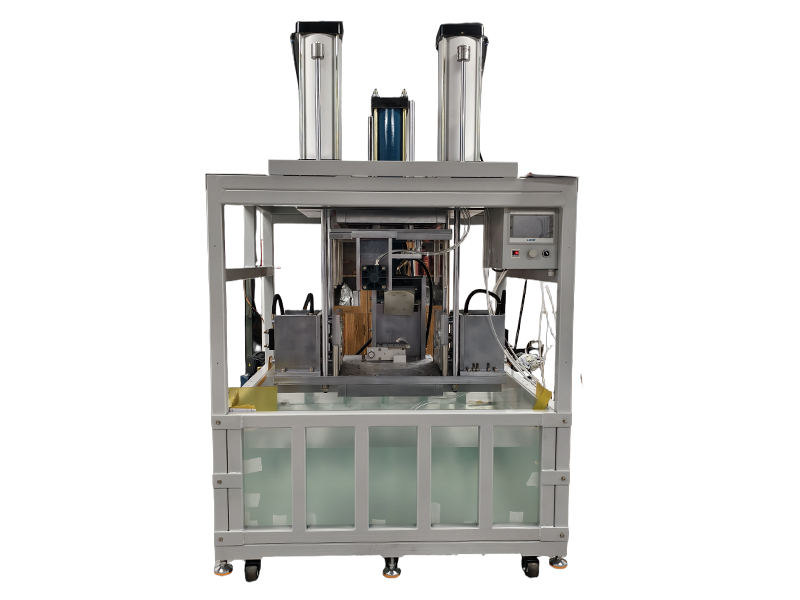

5. Customized Machine Showcase

Due to the testing challenges and specific client requirements described in Section 3, conventional separate-type leak testers could not meet the client’s expectations. WaFu Brothers engineers proposed a custom-built integrated cabinet system, which the client approved and implemented successfully. The final delivered equipment is shown in Fig. 4:

Fig. 4: Customized machine delivered to the client

Fig. 4: Customized machine delivered to the client

6. Conclusion

Through the design and implementation of this transmission housing leak testing solution, WaFu Brothers has further expanded its capabilities in automotive component leak testing. We look forward to collaborating with more partners in related fields to continuously improve sealing quality and promote mutual growth.

WAFU

WAFU