Camera Front Cover Leak Testing, The Pitfall 99% of Factories Will Encounter

1. Pitfall Warning: The Importance of Camera Front Cover Leak Testing

Many factories encounter a common issue during the production and assembly of camera front covers — leakage issues not detected before shipment. Since the front cover seems simple, many assume "water leakage is not a big issue". These seemingly small leaks are often magnified during mass production, leading to returns, warranty claims, and damage to brand reputation. Recognizing and scientifically testing the leak integrity of the camera front cover in advance is the key to avoiding these pitfalls.

2. Why Do Camera Front Covers Need Leak Testing?

The camera front cover is not only an aesthetic protective part, but also the first line of defense for internal electronic components. Its sealing reliability is critical.

| Ensure Image Quality is Not Affected | Dust or particles entering the module can directly attach to the sensor or lens, leading to permanent black spots or blemishes, severely affecting image quality. |

| Extend Product Lifespan | Corrosive substances exist in daily use environments. A good seal protects internal coatings, adhesives, and circuits from chemical erosion, preventing performance degradation. |

| Intercept Assembly Defects | Front cover assembly relies on precise dispensing and pressing. Any deviation in these processes will create leakage channels. Leak testing is the final and most effective checkpoint to intercept these "defective products" before they leave the production line. |

| Reduce Costs and Brand Loss | If untested parts with leakage defects flow into subsequent assembly or even reach end users, the resulting failures will lead to after-sales repair costs, customer complaints, and brand reputation damage, costing tens or even hundreds of times more than the initial testing investment. A small investment in early-stage testing can prevent massive losses later on. |

Figure 1: Camera Front Cover Provided for Testing by the Client

Figure 1: Camera Front Cover Provided for Testing by the Client

3. Testing Challenges

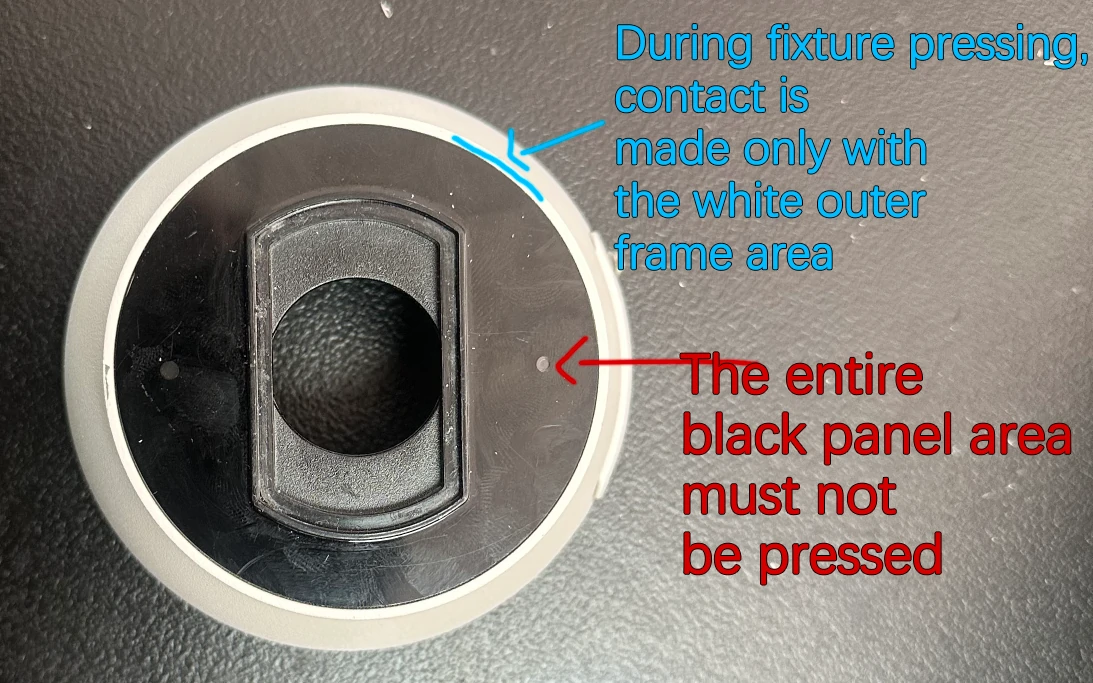

The camera front cover panel is fragile, and the client requires that the fixture pressing should not apply pressure to the front cover panel itself. This has become a key challenge in fixture design.

Solution: The panel has some shell areas around it. After discussion with the client, this area can be used as the pressing point. As shown in Figure 2, the black panel area must not be pressed, and the fixture pressing should only contact the outer white part.

Figure 2: Fixture Pressing Contact Area Diagram for Camera Front Cover

Figure 2: Fixture Pressing Contact Area Diagram for Camera Front Cover

4. Solution Concept

Based on the client's IP67 waterproof requirements and the product's characteristics, the instrument detection time is designed as follows:

- Inflation Time: 5.0S

- Holding Pressure Time: 15.0S

- Testing Time: 15.0S

- Exhaust Time: 2.0S

To meet the fast-paced production line testing, a foolproof design was implemented for the fixture to prevent time wastage caused by incorrect placement.

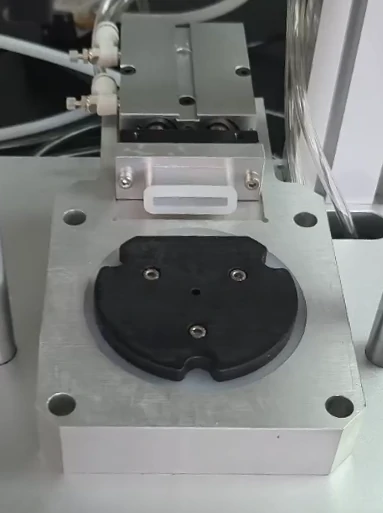

Figure 3: Back View of the Camera Front Cover

Figure 3: Back View of the Camera Front Cover

Figure 4: Fixture Placement Area with Foolproof Optimization Design

Figure 4: Fixture Placement Area with Foolproof Optimization Design

5. Final Product

Based on the client's daily production capacity, a dual-channel leak tester was designed to simultaneously test the waterproof sealing requirements of two camera front covers. The testing instrument connected to the fixture is the WAFU Brothers Multi-channel Leak Tester , which can be customized with the number of channels based on user requirements.

Figure 5: Leak Tester for Camera Front Cover

Figure 5: Leak Tester for Camera Front Cover

6. Testing Process Demonstration

The testing scheme is designed with positive pressure method, testing the product's waterproof performance, with a testing pressure of 12KPa and a leakage limit of 50Pa.

WAFU

WAFU