After Reading This, You'll Understand: Why Leak Testing for Electric Car Wash Brushes Is So Important

1. Product Overview

According to data, by the end of 2024, the global number of vehicles has exceeded 1.4 billion. The electric handheld car wash brush is a cleaning tool driven by a motor that rotates or vibrates the brush head. It is mainly used for cleaning cars, motorcycles, household tools, and outdoor facilities. Compared with traditional manual brushes, it saves effort, improves cleaning efficiency, and works even better when used with water flow or cleaning agents. Its cordless and convenient design makes it widely used in household car cleaning and commercial auto repair shops.

2. Why Do Electric Handheld Car Wash Brushes Require Leak Testing?

Due to the nature of electronic products, they are extremely vulnerable to water damage. Therefore, the waterproof performance of the product must meet standards for several reasons:

| Prevent Water Damage | The car-washing environment involves a large amount of water and strong splashes. If the sealing is poor, water can enter the motor chamber, battery compartment, or control board, causing decreased performance or even short circuits and device failure. |

| Ensure User Safety | Water entering the circuitry may cause electric leakage, posing safety risks to users, so reliable sealing is essential. |

| Market Requirements | Many electric cleaning tools must meet IPX6 (strong water jet protection) or IPX7 (temporary immersion protection) standards. Leak testing is a key method to verify whether the product meets these waterproof ratings. |

| Improve Durability | Good sealing prevents corrosion of internal metal parts, motor moisture damage, and aging or jamming of the transmission structure, significantly extending the product’s lifespan. |

Fig.1: Electric handheld car wash brush produced by the customer

Fig.1: Electric handheld car wash brush produced by the customer

3. Solution Concept

The customer's required testing area is the entire product, using a positive pressure method to test sealing. A customized mold is created for the product. When the fixture clamps down, it encloses the entire product, and air is injected into the fixture. This method—pressurizing around the exterior rather than inside the product—greatly reduces inflation and holding time, significantly shortening the overall testing duration.

4. Testing Challenges

The electric handheld car wash brush provided by the customer is already a finished product. When the fixture clamps down, it must ensure sealing integrity without scratching or damaging the product.

Solution to the Challenge: Technicians applied Teflon to the fixture platform to reduce friction between the fixture and the product, minimizing the risk of scratches.

Fig.2: Teflon applied on the fixture platform

Fig.2: Teflon applied on the fixture platform

5. Final Product

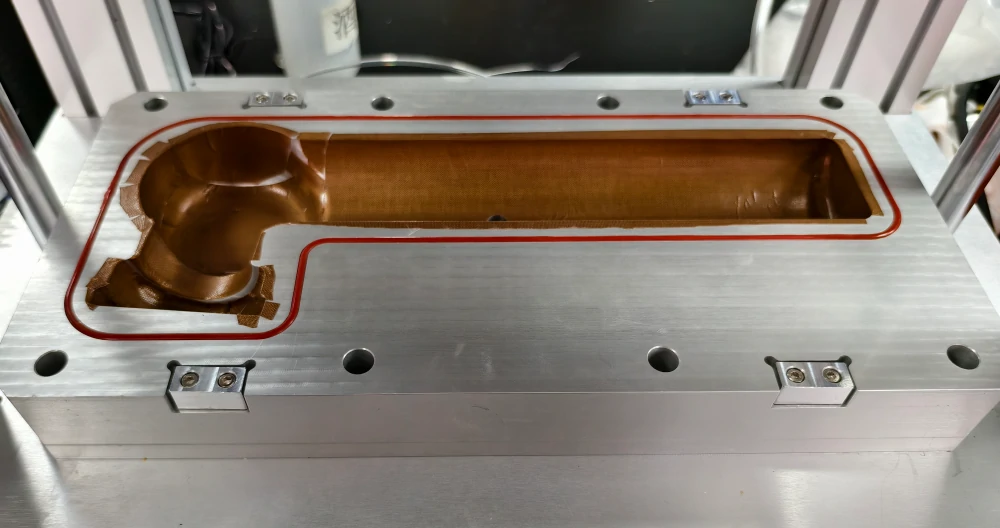

Based on the customer’s production requirements, WaFu Brothers technicians designed a single-channel leak testing system and provided a complete testing solution. After customer approval, customized instruments and matching fixtures were produced. The leak tester connected to the fixture in the picture is the WaFu Brothers Multi-Channel Leak Tester , which can be customized with any number of channels according to user needs. High testing accuracy and fast speed.

Fig.3: Produced WaFu Brothers leak tester and matching fixture

Fig.3: Produced WaFu Brothers leak tester and matching fixture

6. Testing Process Demonstration

The following video demonstrates the leak testing process for the electric handheld car wash brush:

7. Conclusion

We appreciate the customer's trust, which allowed WaFu Brothers to further expand into the electronic device field. In the future, WaFu Brothers will continue to enhance product quality and strive to deliver more efficient, more accurate, and smarter leak testers.

WAFU

WAFU