The Secret the Factory Never Told You: Electronic Cable Leak Testing Case!

1. What Are Electronic Cables?

Electronic cables are components used to connect electrical circuits. They mainly serve the purpose of electrical connection and signal transmission between devices and components, components and cabinets, systems and subsystems, ensuring no signal distortion or energy loss between systems. Their quality directly affects the overall reliability of system operation and they are essential supporting products for equipment manufacturers.

2. Why Do Electronic Cables Require Leak Testing?

Electronic cables require leak testing primarily to ensure they can operate stably and reliably over the long term in high-reliability, harsh, or special application environments. This is not a requirement for all cables, but for certain fields, it is a critical quality control step.

| Moisture and Corrosion Protection | Oxygen, salt (in marine or coastal environments), and industrial gases (such as sulfides) can corrode internal conductors, solder joints, and contacts, causing increased resistance, signal attenuation, or even open circuits. |

| Ensuring Signal Integrity | For high-frequency, high-speed signal transmission cables (such as those used in 5G, radar, or high-end test instruments), performance depends on precise physical structure. Moisture intrusion may alter dielectric material properties, causing impedance changes, signal reflection, and higher loss. |

| Extending Product Lifespan and Reliability | Airtight cables block harmful substances from entering, significantly reducing early failure rates caused by environmental factors and greatly extending the mean time between failures. This is especially important for applications with high maintenance costs or critical locations, such as base stations or subsea optical cable repeaters. |

| Sealing Structures in Cable Design | If electronic cables use over-molding, rubber sealing rings, adhesive potting, waterproof terminals, or similar structures, leak testing is required to verify whether these processes truly achieve sealing. |

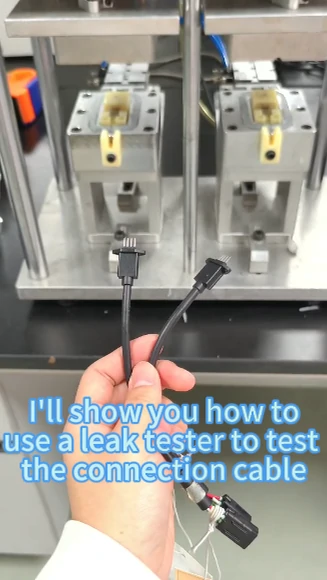

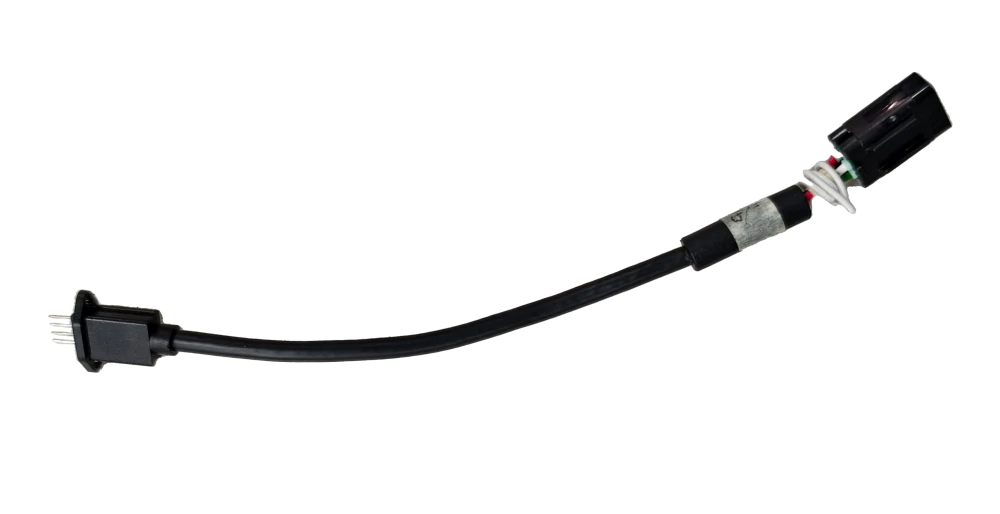

Figure 1: Electronic cable samples provided by the customer

Figure 1: Electronic cable samples provided by the customer

3. Solution Concept

The customer required separate positive-pressure and negative-pressure testing. The fixture is dual-station, allowing two products to be tested simultaneously. Although it is a dual-station fixture, the instrument uses four channels as required: two channels for positive pressure and two channels for negative pressure.

Figure 2: Channel interfaces on the back of the instrument

Figure 2: Channel interfaces on the back of the instrument

4. Testing Challenges

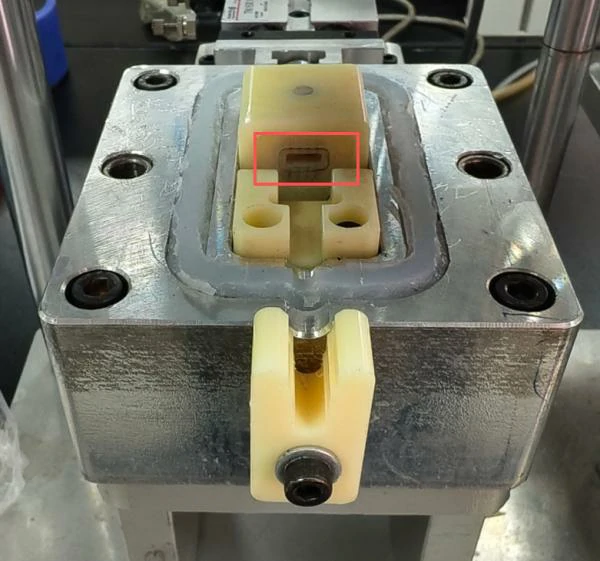

The test position is at the connector end, and the terminals of the customer’s product are very small. Improper fixture design could bend the terminals and damage the product.

Solution: WaFu Brothers engineers designed a small opening in the fixture. During testing, the connector is placed into this opening so that when the fixture presses down, it avoids damaging the terminals while still allowing the airtightness of the terminal area to be tested.

Figure 3: Fixture on the tooling

Figure 3: Fixture on the tooling

5. Final Product

Based on the customer’s requirements, we produced a dual-station multi-function integrated machine capable of performing positive-pressure and negative-pressure leak testing independently. The image shows the customized fixture and instrument. The instrument is the WaFu Brothers Multi-Function Leak Tester , featuring high accuracy, fast testing speed, and a wide testing range to meet various customer needs.

Figure 4: Multi-function leak tester and fixture for electronic cables

Figure 4: Multi-function leak tester and fixture for electronic cables

6. Testing Process Demonstration

The video demonstrates the positive-pressure method. To use a specific testing method, simply connect the air tube from the selected channel to the corresponding port on the fixture. The video below shows the complete leak testing process for electronic cables:

7. Conclusion

Through this electronic cable leak testing case, WaFu Brothers has further enhanced its leak testing capabilities in the electronic harness field. Moving forward, WaFu Brothers will continue improving product quality and after-sales service, striving to build leak testers that offer quality, service, and after-sales support that fully satisfy customers.

WAFU

WAFU