When Leak Testing Is Done Properly, How Much Can After-Sales Costs for E-Cigarette E-Liquid Tanks Be Reduced?

I. What Is an E-Cigarette E-Liquid Tank?

An e-cigarette is an electronic atomization product that heats and vaporizes e-liquid for user inhalation. It typically consists of core components such as a battery, atomization coil, control system, and an e-liquid storage unit. As the key component responsible for storing and delivering e-liquid, the e-cigarette e-liquid tank directly affects user experience as well as overall product safety.

II. Why Do E-Cigarette E-Liquid Tanks Require Leak Testing?

E-cigarette e-liquid tanks are primarily used to contain e-liquid. Their structure usually consists of plastic or metal housings, sealing rings, and oil inlet channels, all of which require extremely high sealing performance. Once the sealing performance is insufficient, issues such as oil seepage, leakage, backflow, oil adhesion, and fogging are very likely to occur. These problems not only affect user experience but may also lead to after-sales complaints and even potential safety hazards.

| Prevent Oil Leakage | If the tank is poorly sealed, e-liquid may leak from gaps or interfaces. This not only causes product waste but may also contaminate other electronic components, affect normal device operation, and even pose a risk of short circuits. |

| Avoid Oxidation and Degradation | The main components of e-liquid (such as propylene glycol, vegetable glycerin, nicotine, and flavorings) may oxidize or volatilize when exposed to air, leading to flavor deterioration, changes in nicotine concentration, or even the formation of harmful substances. |

| Ensure Stable Atomization | E-cigarettes generate aerosol by heating e-liquid through an atomizer. If the tank’s sealing integrity is insufficient, external air may enter abnormally, resulting in unstable atomization pressure and affecting vapor output and taste. |

| Safety Assurance | For nicotine-containing e-liquids, leakage may cause skin contact or accidental ingestion, posing toxic risks to users—especially children and pets who may come into contact with the product. |

Figure 1: E-cigarette e-liquid tank sample provided by the customer

Figure 1: E-cigarette e-liquid tank sample provided by the customer

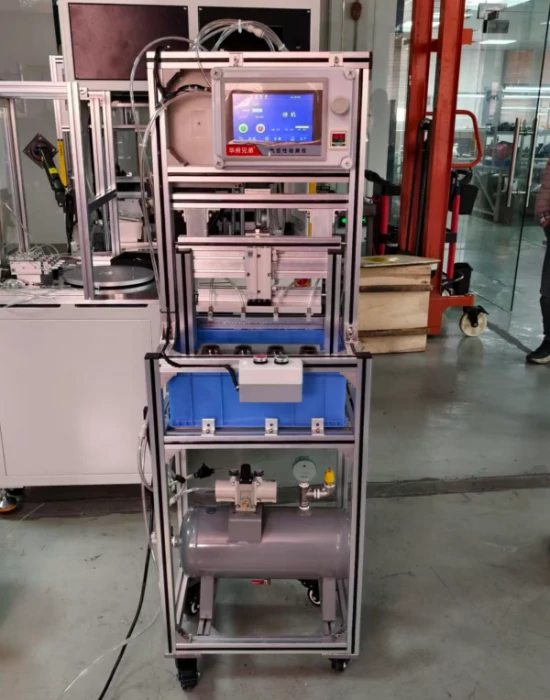

III. Solution Concept

Based on the customer’s production line requirements, a four-station water immersion testing machine was designed. Unlike conventional water immersion leak detection machines that adopt a tabletop design, the multi-station configuration requires higher air pressure. Therefore, this e-cigarette e-liquid tank water immersion testing machine adopts a floor-standing design. According to customer needs, a digital display screen for real-time air pressure monitoring was also provided.

Figure 2: Digital display screen used to monitor real-time air pressure

Figure 2: Digital display screen used to monitor real-time air pressure

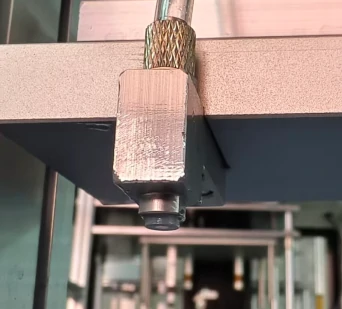

IV. Testing Challenges

The e-cigarette e-liquid tank has a small opening, making it impossible to directly submerge it in the same way as with conventional water immersion leak detection machines.

Solution to the challenge: A fixture is used to apply downward pressure and achieve sealing. After ensuring proper sealing, the platform is then lowered and pressurized.

Figure 3: Fixture used for sealing and pressurization

Figure 3: Fixture used for sealing and pressurization

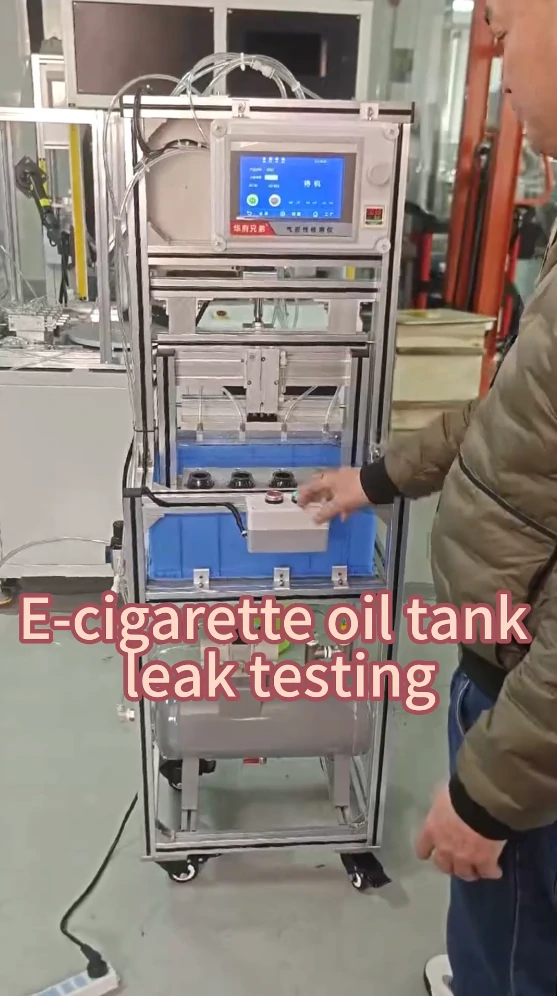

V. Final Product

Based on the customer’s requirements, the final product delivered was a water immersion leak detection machine for e-cigarette e-liquid tanks.

Figure 4: Water immersion leak detection machine for e-cigarette e-liquid tanks

Figure 4: Water immersion leak detection machine for e-cigarette e-liquid tanks

VI. Leak Testing Process Demonstration

In this e-cigarette e-liquid tank leak testing case, the water immersion method is adopted, which allows the leakage location to be identified. The video below demonstrates the testing process:

WAFU

WAFU