Factory Failures of Energy Storage Controllers? Have You Done Leak Testing?

1. What is an Energy Storage Controller?

An energy storage controller, usually referring to an Energy Storage System Controller (ESC), is the core control unit of an energy storage system. It monitors, schedules, and protects the operation of energy storage devices to ensure safe, stable, and efficient system performance. It is mainly used for capacity management and coordinated system control.

2. Why Does an Energy Storage Controller Require Leak Testing?

Since energy storage controllers are often used in high-humidity and high-temperature outdoor or industrial environments, insufficient sealing can easily allow moisture to enter and corrode the circuits. Therefore, leak testing is a crucial step in the production and quality control of energy storage controllers.

| Harsh Operating Environment | Energy storage controllers are usually installed in outdoor energy storage cabinets, photovoltaic systems, wind power systems, and other renewable energy setups. Long-term exposure to rain, humidity, and temperature fluctuations can easily allow external moisture to enter the device if the sealing is inadequate. |

| Protect Core Electronic Components | Energy storage controllers integrate control circuit boards, communication modules, and other electronic components. If sealing is insufficient, moisture may enter, causing corrosion, short circuits, or poor contact, potentially leading to control failure or system malfunctions. |

| Reduce Risk of Accidents | Energy storage systems have high energy density. If the controller fails, charging and discharging may become uncontrolled, seriously affecting the safety of the entire system. Leak testing helps prevent safety risks caused by sealing issues in advance. |

| Improve Product Quality | Conducting leak testing during production can promptly identify assembly or manufacturing defects, reduce batch defects, and save labor and repair time. |

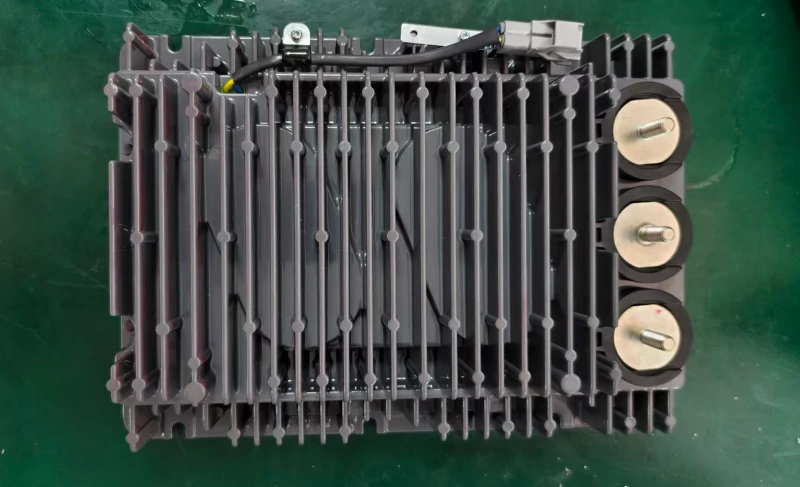

Figure 1: Sample energy storage controller provided by the customer

Figure 1: Sample energy storage controller provided by the customer

3. Solution Concept

The energy storage controllers to be tested are finished products, and the overall product is inspected for sealing defects. Since the customer's production volume is not large, single-channel testing is sufficient for the production line. A negative pressure vacuum method is used, with a test pressure of -30kPa and a leakage limit of -500Pa.

4. Testing Challenges

Because the energy storage controller is a finished product with a complex structure and relatively large size, pressurization and stabilization times are longer.

Solution to the Challenge: WaFu Brothers’ technicians designed a custom fixture that matches the shape of the customer’s product, filling the internal volume to accelerate pressurization and holding time.

Figure 2: Custom fixture for energy storage controller

Figure 2: Custom fixture for energy storage controller

5. Final Product

Based on customer requirements, a dedicated leak tester for energy storage controllers was produced. The image shows the custom fixture and instrument. The connected instrument is WaFu Brothers Multifunction Leak Tester , which supports customization and meets various customer needs. It provides high accuracy, fast testing speed, and wide testing range.

Figure 3: Multifunction leak tester and fixture for energy storage controllers

Figure 3: Multifunction leak tester and fixture for energy storage controllers

6. Leak Testing Process Demonstration

This leak testing case uses a negative pressure vacuum method. The video below demonstrates the testing process:

WAFU

WAFU