Who Determines the Lifespan of Outdoor Cameras? Airtightness Testing Gives the Answer!

1. Product Overview

As society continues to develop, people’s awareness of security is increasing, and the demand for cameras is growing. As a result, more and more manufacturers are launching cameras with diverse functions. For outdoor cameras, most usage scenarios are naturally outdoors. Therefore, in order to extend the service life of outdoor cameras and ensure normal operation during use, waterproof performance is crucial, and the leak tester is the core step in verifying whether the waterproof performance meets standards.

2. Why Should Outdoor Cameras Undergo Airtightness Testing?

Due to the usage environment of outdoor cameras, airtightness testing is mainly performed to ensure that the product can operate normally in harsh conditions and extend its lifespan. The detailed reasons are as follows:

| Prevent Water and Dust Ingress | Outdoor cameras are exposed to rain, fog, dust, and sand for long periods. If the housing is not well sealed, moisture or dust may enter, causing lens fogging or sensor damage. |

| Ensure Electronic Component Stability | Electronic components are sensitive to humidity and dust. Even a small amount of moisture may cause corrosion, short circuits, or signal interference. Airtightness testing confirms the internal seal, ensuring long-term stability of the electronics. |

| Meet Waterproof Rating Standards | Outdoor cameras are usually required to meet protection levels such as IP65, IP66, or IP67 before leaving the factory. Airtightness testing is an essential method to verify these standards. |

| Enhance User Experience | If the sealing is poor, users may experience blurred images or frequent malfunctions, affecting usability. Airtightness testing detects issues before shipment, reducing after-sales costs. |

Figure 1: Outdoor camera housing provided by the client for testing

Figure 1: Outdoor camera housing provided by the client for testing

3. Testing Challenges

The outdoor camera housing produced by the client has many small interfaces, which increases the number of areas that need sealing. Since the product is already a finished item, the fixture must avoid scratches, deformation, or damage to the housing during clamping. These two challenges make the sealing design of the fixture much more difficult.

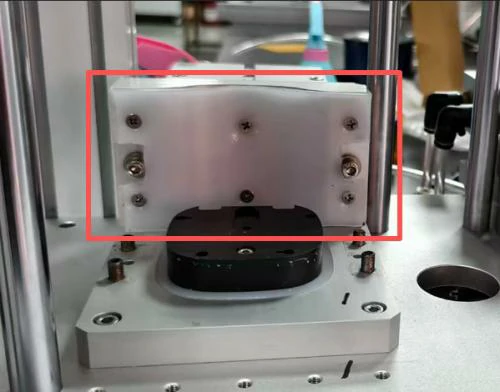

Figure 2: Interface panel on the front housing

Figure 2: Interface panel on the front housing

Solution: WaFu Brothers engineers custom-made sealing components to meet the hardness and specifications required for different products. This ensures fixture airtightness without compressing or damaging the client’s product.

Figure 3: Silicone sealing part used to seal the rear interface panel

Figure 3: Silicone sealing part used to seal the rear interface panel

4. Solution Design

The client needed to test the entire camera housing to ensure that its waterproof performance met the required standard. Since the outdoor camera consists of two separable parts (front and back), WaFu Brothers engineers designed the tooling to test both parts separately instead of as a whole. This approach allows for identifying which part fails the airtightness test, quickly locating quality issues and improving testing efficiency.

To meet the client’s request for real-time pressure monitoring, the engineers added a digital display panel in the upper right corner to show the current air pressure.

Figure 4: Custom panel for real-time air pressure monitoring

Figure 4: Custom panel for real-time air pressure monitoring

5. Final Product

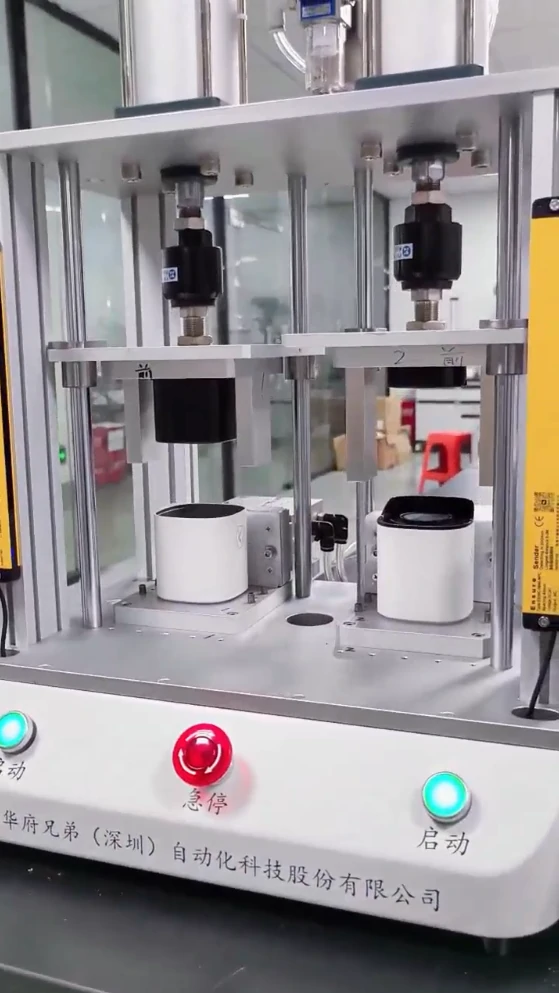

Based on production needs, the client customized multiple sets of airtightness testing fixtures. The device shown in the image is a dual-channel leak tester, designed to test the waterproof sealing of two front camera housings simultaneously. The fixture is connected to a WaFu Brothers multifunctional leak tester , which can be customized for different channel quantities according to user requirements. It offers highly accurate and fast results and is suitable for electronics, home appliances, and hardware die-casting industries to test airtightness, sealing, and waterproof performance.

Figure 5: One of the customized WaFu Brothers leak testing systems

Figure 5: One of the customized WaFu Brothers leak testing systems

6. Testing Process Demonstration

The testing method adopts the positive pressure method to verify the product’s sealing performance. The demonstration video shows another customized machine that tests both the front and back parts of the outdoor camera simultaneously. The video below presents the testing process:

7. Conclusion

We appreciate our client’s trust in the outdoor camera industry and the opportunity for multiple collaborations. WaFu Brothers’ leak testers have become more deeply integrated into camera manufacturing, helping clients continuously improve product quality. Moving forward, WaFu Brothers will continue to optimize assembly efficiency, shorten production cycles, and allow clients to benefit earlier from high-efficiency, high-precision, and highly automated airtightness testing solutions.

WAFU

WAFU