Technicians Were Shocked: Real Leak Testing Case of Wire Harness Connectors!

1. What Is a Wire Harness?

A wire harness refers to an electrical connection assembly composed of multiple wires or cables bundled and organized according to circuit requirements, along with terminals, connectors, sleeves, and other components. It is a fundamental part of modern electronic devices for transmitting power and signals.

2. Why Do Wire Harness Connectors Need Leak Testing?

As wire harness connectors are used for electrical and signal connections in electronic equipment, they are naturally very vulnerable to moisture intrusion. To ensure waterproof performance, the following key factors must be considered:

| Prevent Liquid Ingress | In humid or liquid environments, if there is leakage in the harness or connector interface, moisture may seep in, causing reduced insulation, short circuits, or corrosion. |

| Ensure Electrical Safety & Performance | Air leakage or water ingress may lead to short circuits, signal interference, or electrical failure. Leak testing can detect potential leakage points in advance to ensure long-term stable operation. |

| Withstand Harsh Environments | Many components in modern vehicles and devices operate in extreme environments. Leak testing ensures that wire harnesses maintain performance under all conditions. |

| Meet Industry Standards | High-end electronics, automotive, and aerospace industries require strict waterproof, dustproof, and leak-proof standards. As connectors for such equipment, wire harnesses must ensure reliable sealing and waterproof performance. |

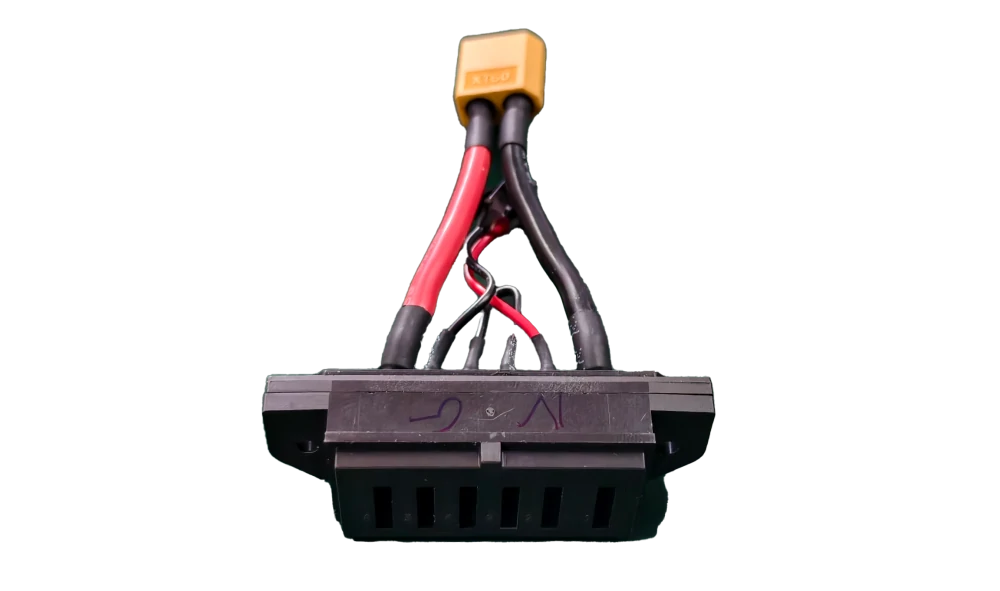

Figure 1: Defective wire harness connector sample provided by customer

Figure 1: Defective wire harness connector sample provided by customer

3. Solution Concept

This leak test mainly focuses on the glue-sealed area where each wire joins the connector, inspecting for leakage. Based on the customer's required hourly output, the equipment must support dual-channel testing to ensure the testing speed keeps up with production.

4. Testing Challenges

As the wires are soft, using a traditional fixed mold would require precise wire placement during loading. This would be time-consuming and may cause friction damage to the wires.

Solution: The WaFu Brothers technical team designed a box-style fixture. During testing, the wire harness connector can be placed directly inside without precise adjustment, while still ensuring that the glue-sealed area of each wire is properly tested. This greatly improves efficiency and reduces labor.

Figure 2: Mold on the fixture

Figure 2: Mold on the fixture

5. Final Product

Although the dual-cavity fixture appears to hold two products in one space, the internal chamber is divided. Air is supplied and tested separately for each connector. The leak tester shown in the image is the WaFu Brothers multifunctional leak tester , which can accurately detect both micro leaks and large leaks. Its sensors are highly precise, and the instrument is fully intelligent.

Figure 3: WaFu Brothers leak tester and fixture

Figure 3: WaFu Brothers leak tester and fixture

6. Testing Demonstration

The following video demonstrates the leak testing process for wire harness connectors:

7. Conclusion

Through this wire harness connector leak testing case, WaFu Brothers has established strong capability in connector testing solutions. In the future, we will continue to enhance product design and focus on R&D to deliver more precise and wider-range leak testing equipment.

WAFU

WAFU