Leak Testing Case for Automotive Engine Hood Die-Cast Parts

August 25, 20251. Why Perform Leak Testing on Engine Hood Die-Cast Parts?

In automotive engine manufacturing, the engine hood die-cast part is a critical component that directly affects the engine's sealing performance and reliability. This part operates under high temperature, high pressure, and vibration for extended periods. Any tiny leaks can not only cause fuel leakage inside the engine compartment but also reduce engine performance, increase fuel consumption, and even create safety hazards.

Therefore, performing strict leak testing before the die-cast parts leave the factory can effectively filter out products with potential defects, ensuring the engine maintains stable performance under complex working conditions.

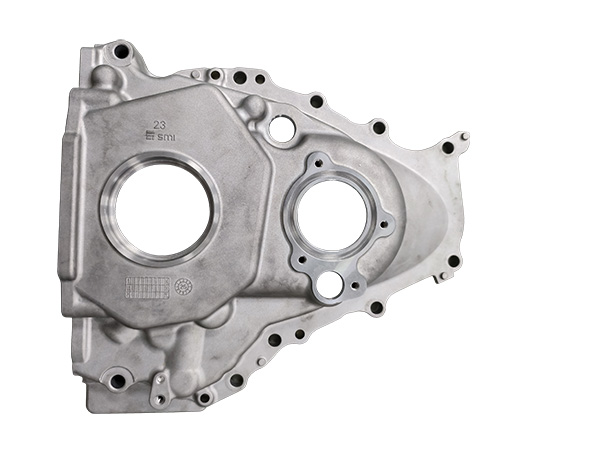

Figure 1: Engine Hood Die-Cast Part

Figure 1: Engine Hood Die-Cast Part

2. Main Testing Positions of Engine Hood Die-Cast Parts

The object of this test is the automotive engine hood die-cast part. The part has a complex structure, including multiple screw holes and cavities, and all sealing points must be ensured. Customers require rapid detection of sealing issues during mass production, with the ability to further identify leak points as needed.

Figure 2: Engine Hood Die-Cast Part

Figure 2: Engine Hood Die-Cast Part

3. Operation Steps for WaFubrother Sealing Tester

To meet the customer's requirements, we customized an integrated sealing and water-leak testing instrument, featuring dual-station detection capable of testing two different products simultaneously. The instrument supports two testing modes: positive pressure leak testing with high-precision sensors for efficient sealing verification, and water-leak testing for quickly locating leaks. The operating steps are as follows:

- Workpiece Clamping: Place the engine hood die-cast part into a dedicated sealing fixture, ensuring all interfaces are properly sealed.

- Pressurization Test: The instrument automatically fills the part cavity with gas at the preset pressure.

- Pressure Monitoring: High-precision sensors detect whether the cavity pressure drops.

- Result Judgment: If the pressure remains stable → Pass; if the pressure drops beyond the set threshold → Fail, and the leakage level is indicated.

- Leak Point Detection: If leakage occurs, use the rotary switch to activate water-leak testing and visually locate the leak points.

4. Video Demonstration of the Testing Process

Video: Leak Testing Process

With this integrated sealing testing solution, the customer achieved efficient and precise inspection of the automotive engine hood die-cast parts: ensuring product sealing reliability while visually locating leaks through water-leak testing, facilitating process improvements.

WAFU

WAFU