Frequent Leaks in Robotic Vacuums? The Problem Lies in the Plastic Float Ball’s Leak!

1. Product Overview

With the rise of smart home appliances, more and more households are using robotic vacuum cleaners. The plastic float ball, as a key component of the robotic vacuum, plays a crucial role in its operation. It is usually installed inside the water tank or waste water compartment to monitor water levels and control water flow. When the water level rises or falls, the float ball triggers sensor signals through changes in buoyancy, enabling automatic water stop or refill.

2. Why Perform Leak Testing on the Plastic Float Ball?

Since the float ball operates in a consistently wet environment, even minor leaks can cause errors in float detection or electronic short circuits, resulting in full machine malfunctions. Therefore, its leak is a critical quality control point. Small leaks of gas or liquid may lead to the following issues:

| Buoyancy imbalance, inaccurate detection | If the float ball takes in water or leaks air, the internal air volume changes, causing reduced buoyancy and inaccurate water level sensing, which leads to incorrect water level judgment. |

| Electronic system misoperation | The float ball works with sensors to control the water valve. Signal deviations may cause continuous water flow or overly wet mopping. |

| Damage to electronic components | Some robotic vacuum designs include electronic components inside the float ball. If leak is insufficient, these components may be damaged. |

| Reduced overall waterproof rating and lifespan | A leaking float ball may become the weak point of the vacuum's waterproof system, affecting the overall IP waterproof rating. |

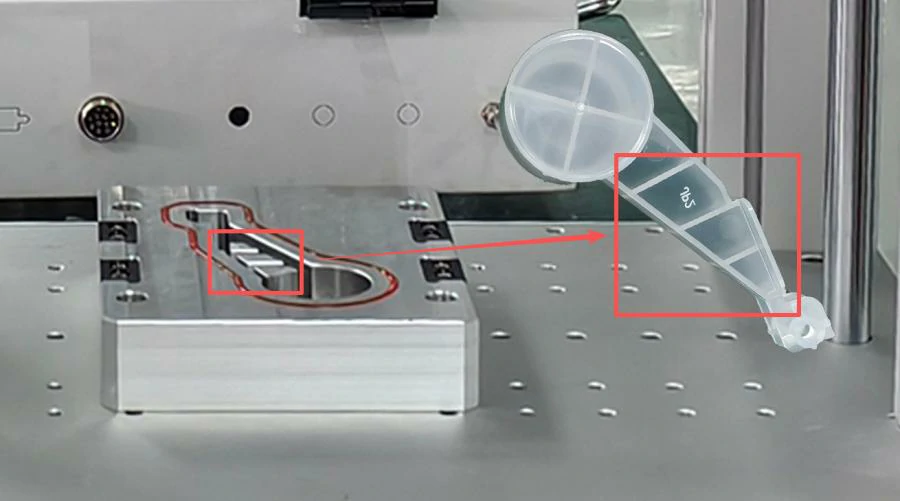

Figure 1: Plastic float ball used by the customer for testing

Figure 1: Plastic float ball used by the customer for testing

3. Basic Solution Concept

The customer required leak testing for the entire plastic float ball to ensure that overall airtightness meets the standard. To improve testing efficiency, WaFu Brothers’ engineers designed a structural protrusion in the center of some open areas of the product when creating the custom fixture, positioning it at the product’s central point. This protrusion is not meant to block any openings; rather, it is used to reduce the internal volume at that point, accelerating inflation and pressure-holding speed, thereby speeding up the testing process. As shown in Figure 2:

Figure 2: Protrusion corresponding to the product structure

Figure 2: Protrusion corresponding to the product structure

4. Testing Challenges

In leak testing of the robotic vacuum plastic float ball, the sealing of the fixture is the biggest challenge and the most critical step. The fixture's sealing ring ensures tight contact when the fixture is clamped, preventing false readings caused by leaks during testing.

WaFu Brothers’ engineers addressed this challenge by producing custom sealing rings. The fixtures of WaFu Brothers’ leak testers are equipped with tailor-made sealing rings designed specifically for the unique characteristics of each customer’s product. Drawing on 16 years of experience in the field of leak testing, these custom-made sealing rings ensure high-precision sealing during testing and prevent any damage to the product when pressure is applied by the fixture. Every sealing ring used in WaFu Brothers’ fixtures is self-produced.

5. Final Product

WaFu Brothers engineers designed a complete leak testing solution, including instruments, methods, fixtures, and tooling. After adoption, the customer integrated the solution into production with trained personnel to ensure accurate results. Shown in the image is the completed leak tester with custom fixture, connected to the WaFu Brothers multifunction leak tester, which supports multiple testing methods, fast testing speed and precise results, and is suitable for home appliances, hardware die-casting, packaging, and other fields for leak, sealing, and waterproof testing.

Figure 4: Completed leak tester with custom fixture

Figure 4: Completed leak tester with custom fixture

6. Leak Testing Process Demonstration Video

The testing method uses positive pressure sealing. The video below demonstrates the testing process:7. Conclusion

This custom leak testing solution for robotic vacuum plastic float balls helped WaFu Brothers’ client improve product quality and expand the application of leak testing technology in smart home appliances. In the future, WaFu Brothers will continue to optimize testing

WAFU

WAFU