Why Do Top Sweeping Machine Brands Choose This Leak Testing Solution for Their Water Control Components?

1. Product Overview

With the rapid development of modern technology, more and more manufacturers are launching a wide range of smart home appliances. As competition intensifies, each brand offers devices at different price levels. Smart appliances are no longer luxuries but have become an indispensable part of modern family life. Among them, the Sweeping Machine, as an essential household cleaning device, is no longer limited to vacuuming functions. Some models are now equipped with automatic water-dispensing systems to enhance mopping performance. In this system, the water control component serves as a core part, precisely regulating water flow to ensure optimal cloth moisture, balancing cleaning power and floor protection.

2. Why Is Leak Testing Necessary for the Sweeping Machine’s Water Control Component?

As the key part that controls water flow in the Sweeping Machine, even minor leakage in the water control component can lead to abnormal water dispensing or blockage. This not only affects the mopping function but can also interfere with normal cleaning performance due to water leakage. Such issues are closely related to user experience and serve as a critical indicator of product quality and manufacturing consistency.

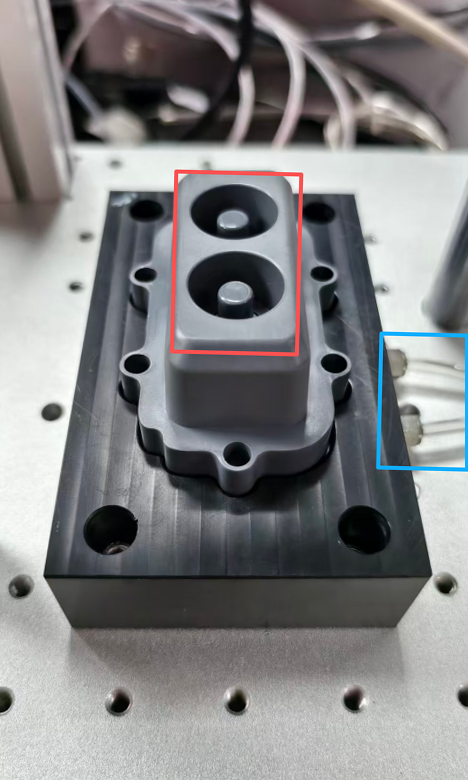

Figure 1: Customer-produced Sweeping Machine Water Control Component

Figure 1: Customer-produced Sweeping Machine Water Control Component

3. Basic Solution Concept

Each water control component produced by the customer is equipped with two independent control devices, responsible for water inlet and outlet regulation. Therefore, to ensure the part’s leak, a dual-channel testing method is required — the Leak Tester must simultaneously deliver air through two independent pipelines into two testing ports and detect any leakage individually. The red boxes in Figure 2 mark the two test ports of the water control component, while the blue boxes indicate the dual-channel air inlet interfaces of the Leak Tester.

Figure 2: Placement Diagram of the Sweeping Machine Water Control Component

Figure 2: Placement Diagram of the Sweeping Machine Water Control Component

4. User Requirements and Implementation

After communicating with the customer to understand their daily production volume and efficiency targets, WAFU Brothers engineers designed a four-channel air intake solution. This setup enables simultaneous testing of two products at once, with each component’s two control units assigned to independent testing channels, allowing accurate assessment of their airtight performance. The detection method applies the Positive Pressure Method: air is introduced into the test ports, and once pressure stabilizes, the system monitors pressure changes and leakage rates in real time. When the measured value exceeds the preset threshold, the product is identified as defective. Test results are clearly displayed on a large screen and accompanied by voice report notifications.

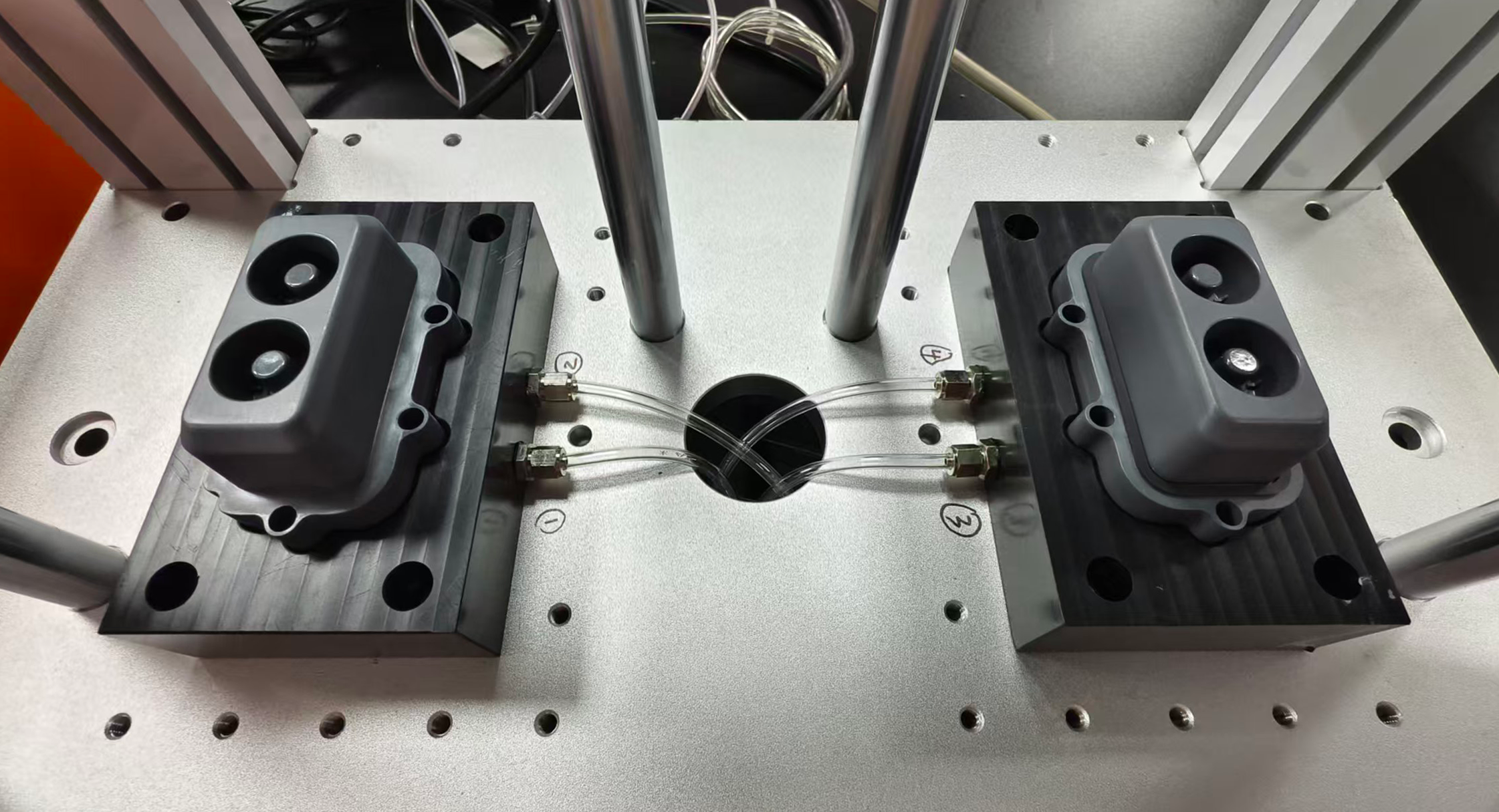

Figure 3: Four-Channel Leak Testing for Sweeping Machine Water Control Components

Figure 3: Four-Channel Leak Testing for Sweeping Machine Water Control Components

Figure 4: Instrument Screen Display Corresponding to Four Air Inlet Channels

Figure 4: Instrument Screen Display Corresponding to Four Air Inlet Channels

Ultimately, WAFU Brothers engineers developed a comprehensive Leak Testing Solution including testing instruments, methods, fixtures, and jigs, supported by professional testing staff to ensure result accuracy. The solution was submitted to the client and later adopted in production. The figure below shows the finalized Leak Tester and fixture system. The connected Leak Tester is the WAFU Brothers Multi-Channel Leak Tester , which supports customized testing methods, offering high efficiency and high precision. It is applicable to home appliances, automotive manufacturing, and medical devices across multiple industries.

Figure 5: Final Produced Leak Tester

Figure 5: Final Produced Leak Tester

5. Conclusion

Through this customized Leak Testing Solution for Sweeping Machine water control components, WAFU Brothers helped the customer significantly improve product consistency and quality, while expanding the application of leak testing technology within the smart home appliance sector. Moving forward, WAFU Brothers will continue to optimize testing technology and fixture design, enhancing the craftsmanship of its Leak Testers and striving to provide efficient, precise, and intelligent leak testing services to help more industries strengthen their quality competitiveness.

WAFU

WAFU