Hermetic Electrical Connector Leak Detection Solution

1. Importance of Hermetic Electrical Connectors

In the aerospace industry, hermetic electrical connectors are responsible for transmitting signals and delivering power between critical electronic components. These connectors must maintain absolute hermeticity under extreme conditions—including vacuum, drastic temperature fluctuations, and high-intensity vibrations. Even the slightest leak could result in:

- Ingress of oxygen and moisture causing circuit corrosion

- Gas release in vacuum leading to dielectric breakdown

- Condensation due to rapid temperature changes

- Decreased system reliability, endangering mission safety

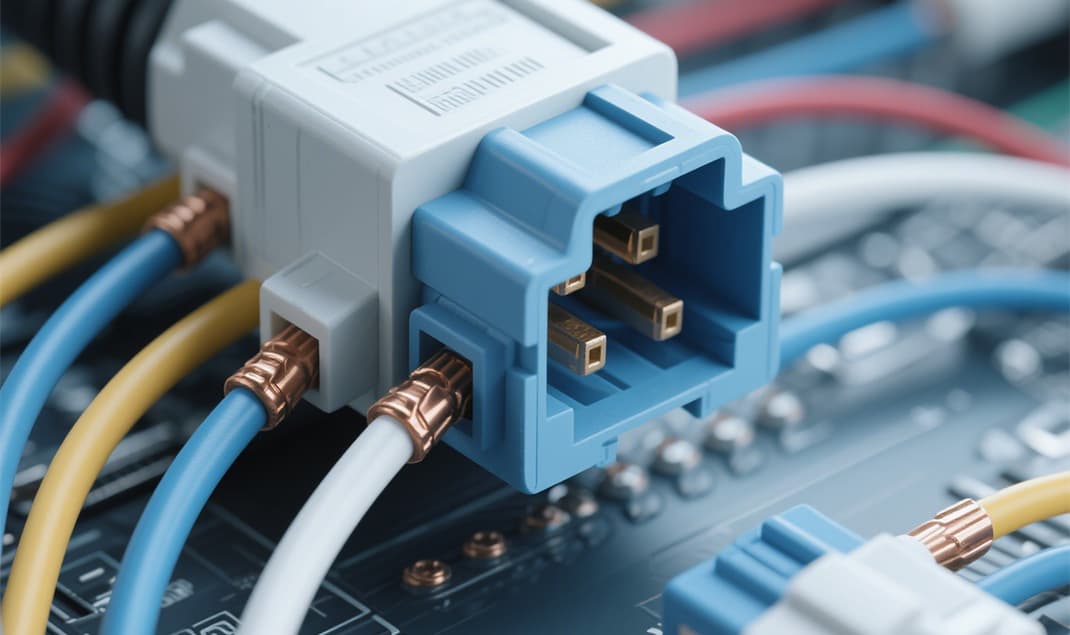

Figure 1: Aerospace-grade Hermetic Connector

Figure 1: Aerospace-grade Hermetic Connector

Data Alert

According to NASA statistics, about 15% of electronic system failures are directly linked to connector hermeticity failures, making leak detection an essential step in aerospace connector manufacturing.

2. Three-Level Detection System

To meet the stringent requirements of aerospace connectors, we offer a three-level leak detection system that ensures compliance across various use cases:

| Detection Level | Method | Sensitivity | Test Time | Application Stage |

|---|---|---|---|---|

| Production Line Screening | Pressure Decay Method | 1×10⁻⁴ cc/s | < 30s/piece | 100% Inline Inspection |

| Precision Testing | Helium Mass Spectrometry (Accumulation Method) | 1×10⁻⁶ cc/s | 2–5 min/piece | Sample Testing / Critical Models |

| Ultimate Testing | Helium Mass Spectrometry (Vacuum Chamber Method) | 1×10⁻⁹ cc/s | 10–15 min/piece | Type Test / First Article Validation |

3. Typical Detection Process

Using a D-sub hermetic connector for satellites as an example, the complete testing process includes:

| Stage | Detailed Steps |

|---|---|

| Pre-processing | Automatic barcode scanning for product information |

| Automated fixture adjustment to match configuration | |

| System self-calibration (zeroing, reference leak rate) | |

| Clamping | Operator places test piece |

| Hydraulic sealing mechanism clamps automatically (adjustable 5–50 N·m) | |

| Optical alignment system verifies clamping | |

| Testing | System auto-selects pre-set program (MIL-DTL-38999 standard) |

| Performs 3 pressure cycles (−100kPa to +200kPa) | |

| Real-time pressure decay curve monitoring | |

| Judgment | System compares measured data with reference curve |

| Automatically generates test report (includes pressure curves, leak rate, test result) | |

| Laser marking for OK parts, audio-visual alarm for NG parts |

4. Conclusion

The hermeticity of electrical connectors is vital to the reliability and safety of aerospace systems. With our three-level detection framework and standardized inspection process, each connector is guaranteed to meet the rigorous demands of space environments—providing a solid foundation for mission success.

WAFU

WAFU