How Do Environmental Factors Affect Airtightness Testing of Products?

In the process of industrial product sealing inspection, leak testing serves as a critical procedure to ensure product quality, and the accuracy of its results directly impacts product safety and reliability. However, environmental factors such as temperature fluctuations and noise can significantly interfere with the test results. Drawing on 16 years of industry experience, WAFU Brothers provides a detailed explanation of how environmental factors affect product testing and the solutions available.

How Do Environmental Factors Interfere with Leak Testing?

The core principle of a leak tester is to place the product inside a sealed fixture, inject air into the fixture, and then use a high-precision leak tester to determine changes in air pressure within the sealed fixture. Environmental factors interfere with this process by altering the physical properties of the gas or affecting the sensitivity of the testing equipment, thereby directly disrupting the accuracy of the results.

What Is the Principle Behind the Impact of Temperature Changes?

The pressure and volume of gas fluctuate significantly with temperature changes, and this characteristic directly affects the baseline data of leak testing. In some workshops where the temperature is more than 10°C higher than the standard testing environment (25°C), according to the gas law (PV=nRT), gas pressure can increase by about 3–5%. Similarly, when the temperature decreases, the gas pressure also changes. However, conventional leak testers, in pursuit of high-precision detection, often lack temperature compensation functionality, which can lead to up to a 5% increase in misjudgment rates, posing a significant risk to product safety.

So How Can the Impact of Environmental Factors Be Solved?

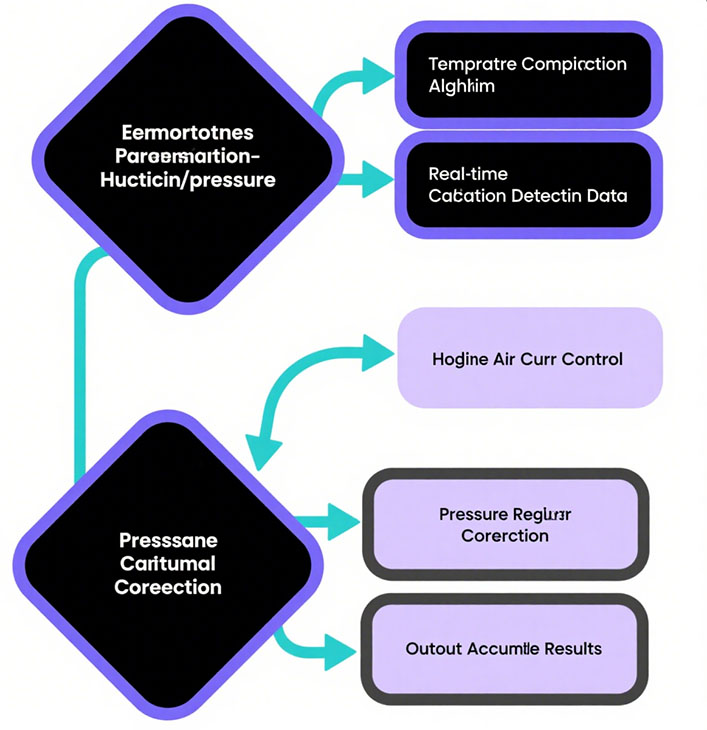

To address environmental interference, WAFU Brothers has developed an anti-interference detection system through three dimensions: hardware upgrades, intelligent algorithms, and gas circuit optimization, enabling high-precision testing in all environments.

Multi-Parameter Real-Time Compensation Technology: Dynamically Offsetting Environmental Impact

The tester is equipped with an integrated temperature, humidity, and pressure sensor that collects 10 sets of environmental data per second and uses embedded algorithms to continuously correct testing baselines in real time. When the ambient temperature varies within the 10–40°C range, the system automatically applies a temperature–pressure compensation curve (modeled from 100,000 sets of laboratory data), keeping temperature-induced errors within ±0.2% FS. For humidity interference, an innovative “dry gas curtain” technology is applied: a tiny stream of dry gas (flow rate < 5 ml/min) at the testing interface prevents moisture from adhering to sealing surfaces, reducing missed detection rates in high-humidity environments to below 0.5%.

Anti-Interference Gas Circuit Design: Building a Stable Testing Environment

The gas circuit system adopts a three-stage filtration + pressure buffering structure: the primary filter removes dust and moisture from the air (filtration precision 0.1 μm), the secondary filter achieves gas drying (dew point ≤ -40°C), and the tertiary filter ensures gas cleanliness reaches CLASS 1. The buffer tank is designed to be 5 times the testing volume, effectively absorbing external pressure fluctuations (within ±5 kPa), thereby improving gas circuit pressure stability to ±0.01 kPa/min. In addition, the testing interface uses a dual-sealing structure, combined with an anti-airflow shield, which can resist airflow disturbances of up to ≤2 m/s in workshops.

Intelligent Diagnostics and Adaptive Adjustment: Early Warning of Potential Interference

The equipment is equipped with an AI health diagnostic system, which analyzes trends in environmental parameter changes and the stability of testing data to issue early warnings 15 minutes in advance of potential interference risks (such as sudden humidity increase or abrupt pressure changes). It then automatically initiates countermeasures (e.g., strengthening the dry gas curtain, switching to a backup gas source). For long-term environmental deviations (such as in high-altitude regions), the system can learn and generate customized compensation models, maintaining testing accuracy at the level of 0.1 Pa·m³/s. In one case, an automotive parts factory located on a plateau applied this technology and successfully reduced testing errors from 12% to 0.8%.

| Environmental Factor | Error in Traditional Test Equipment | Error in WAFU Brothers Tester | Improvement |

|---|---|---|---|

| Temperature (10–40℃) | ±3.5%FS | ±0.2%FS | 94% |

| Humidity (30–90% RH) | ±2.8%FS | ±0.3%FS | 89% |

| Air Pressure (80–110 kPa) | ±4.2%FS | ±0.5%FS | 88% |

| Airflow (≤2 m/s) | ±5.0%FS | ±0.4%FS | 92% |

Conclusion: Breaking Environmental Limits Through Technological Innovation

The interference of environmental factors in leak testing is not an insurmountable problem; the key lies in building a complete “perception–compensation–anti-interference” solution. WAFU Brothers leak testers minimize environmental impact through multi-parameter real-time compensation, anti-interference gas circuit design, and intelligent adaptive adjustment, providing stable and reliable testing assurance for industries such as automotive, medical, and electronics. As industrial manufacturing continues to demand higher quality, environmental adaptability will become a core competitiveness of leak testing equipment, and technological innovation is the key to overcoming environmental limitations and achieving precise testing.

WAFU

WAFU