WAFU Brothers’ Innovative Fixture Design: Breaking Airtightness Testing Efficiency Bottlenecks and Strengthening Stability

In the airtightness testing process, fixtures serve as the "bridge" connecting the testing equipment and the workpiece under test. The design level of the fixture directly determines testing efficiency and data stability. From mass production of automotive parts to precision inspection of medical devices, traditional fixtures often suffer from positioning deviations, time-consuming clamping, and poor adaptability, resulting in low testing efficiency and significant data fluctuations. Leveraging over a decade of industry experience, WAFU Brothers focus on innovative design concepts and cutting-edge technologies to develop a series of high-performance airtightness testing fixtures that fundamentally address these industry pain points, becoming a key force in improving testing efficiency and stability.

Challenges of Traditional Fixtures: The Dual Shackles of Efficiency and Accuracy

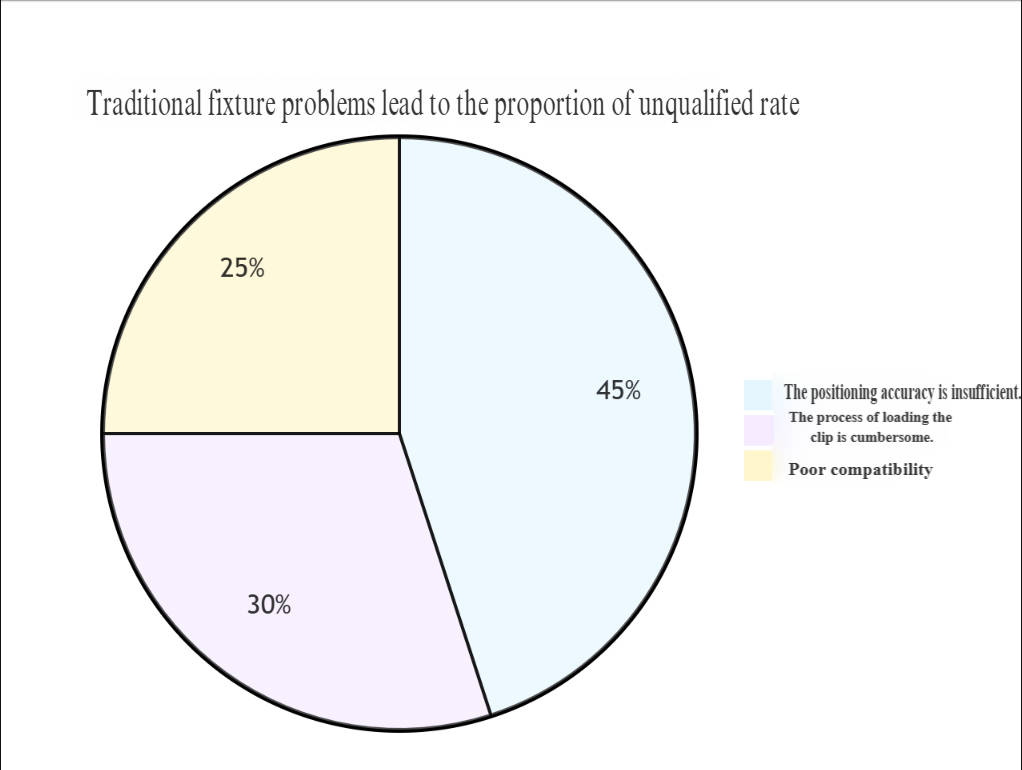

Traditional airtightness testing fixtures generally face three major shortcomings that severely limit production efficiency. First, insufficient positioning accuracy leads to testing deviations. Some fixtures, due to structural design flaws, cannot precisely fix the workpiece, causing inaccurate detection of gas leakage paths. According to the "2023 Global Manufacturing Quality Control Report", the failure rate caused by fixture positioning errors reaches 18%. Second, complicated clamping processes: manual adjustment of fixtures is time-consuming, with clamping time exceeding 3 minutes per piece, which fails to meet large-scale production demands. A leading automotive parts company reportedly lost about 200 effective working hours monthly due to low efficiency of traditional fixtures. Third, poor adaptability: traditional fixtures are often designed for single-use per machine; frequent replacements are required for different sizes and shapes of workpieces, increasing equipment costs and reducing fixture lifespan due to repeated disassembly. The International Organization for Standardization's ISO 9001:2015 Quality Management System clearly states that insufficient equipment adaptability significantly affects production stability and product consistency.

WAFU Brothers’ Innovative Design: Multidimensional Breakthroughs in Industry Barriers

WAFU Brothers have developed airtightness testing fixtures that balance efficiency and stability through three core technologies: modular structure, intelligent adjustment system, and material optimization.

Modular Design: Flexible Adaptation for All Scenarios

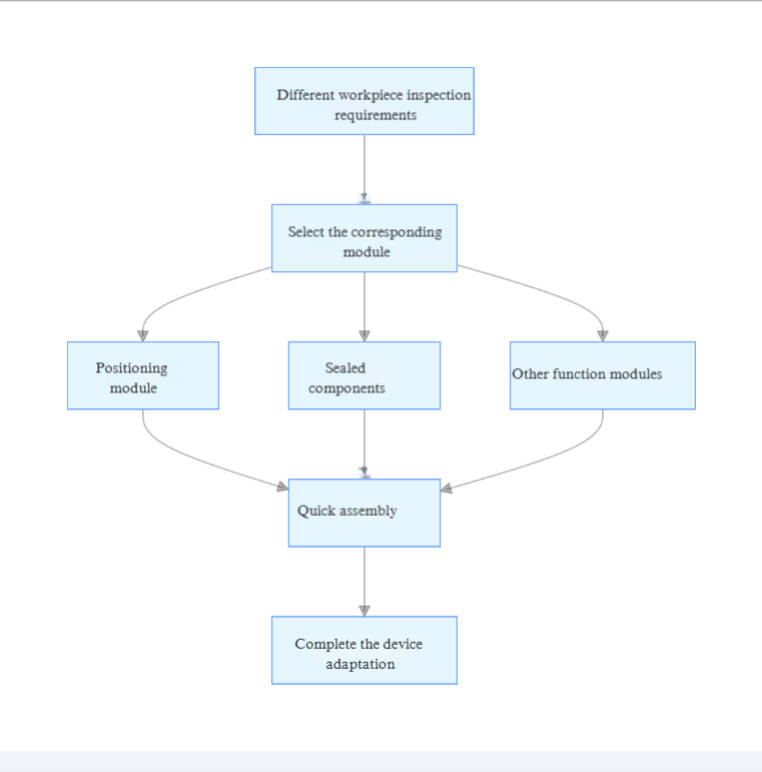

The fixtures adopt a quick-disassembly modular structure with standardized interface design, enabling free combination of fixture components for different specifications. For example, for automotive engine blocks, consumer electronics shells, and other varied workpiece shapes, simply replacing positioning modules and sealing components completes equipment adaptation, reducing switching time to under 30 seconds. This design greatly lowers enterprise equipment investment costs and supports rapid production line transitions, improving production flexibility by over 40%. According to research published in Journal of Mechanical Design and Manufacturing Engineering, modular design effectively enhances equipment versatility and maintenance efficiency.

Intelligent Adjustment System: Precise Positioning and Efficient Clamping

Innovatively integrating electric servo drive and pressure sensing technology, the fixture can automatically recognize workpiece dimensions and adjust clamping force. When testing new energy vehicle battery packs, the system uses built-in sensors to monitor pressure distribution in real time, ensuring 99.5% adhesion between the sealing ring and workpiece surface, avoiding detection errors caused by overpressure deformation or underpressure leakage. Meanwhile, the electric clamping process is automatically executed by a PLC control system, compressing single-piece clamping time to 45 seconds — more than 3 times faster than traditional manual fixtures. This technology has been granted a patent by the National Intellectual Property Office.

| Comparison Item | Traditional Manual Fixture | WAFU Brothers Intelligent Fixture |

|---|---|---|

| Single-piece Clamping Time | >3 minutes | 45 seconds |

| Positioning Error Range | ±0.5 mm | ±0.02 mm |

| Clamping Force Adjustment | Manual | Automatic |

| Detection Data Fluctuation Range | ±0.5 kPa | ±0.05 kPa |

Material and Process Optimization: Ensuring Long-Term Stability

In material selection, WAFU Brothers adopt a composite of high-strength aerospace aluminum and special engineering plastics, ensuring lightweight fixtures (60% lighter than steel fixtures) with excellent corrosion and wear resistance. Key components’ surfaces are treated with nano-coatings, extending service life beyond 8 years. Furthermore, sealing components use food-grade silicone materials, certified by the FDA, meeting high cleanliness requirements of medical and food industries, ensuring no contamination risk during testing.

Related material performance test results have been published in the Journal of Materials Science and Engineering.

Application Effectiveness: Verified Benchmarks Across Multiple Industries

Automotive Manufacturing: Improved Production Efficiency and Yield

After adopting WAFU Brothers’ fixtures, a leading automotive company improved engine block testing efficiency by 60%, reducing single-piece testing cycle from 8 to 3 minutes. The fixture’s high positioning accuracy shrank data fluctuation range to ±0.05 kPa, and first-pass product yield jumped from 88% to 97%, saving over 5 million RMB annually in rework costs.

Medical Devices: Meeting Strict Cleanliness and Precision Requirements

In airtightness testing for medical syringes, WAFU Brothers’ customized fixtures, featuring dust-free design and sub-millimeter positioning accuracy, successfully passed the ISO 13485 Medical Device Quality Management System certification. The fixture’s automatic calibration ensures clamping error below 0.02 mm each time, helping the enterprise achieve 100% EU CE certification compliance.

Consumer Electronics: Tackling Small Size and High Precision Challenges

For waterproof testing of smartphones, WAFU Brothers developed a vacuum suction fixture using negative pressure to fix curved glass covers, avoiding scratches caused by traditional clamping methods. Coupled with automated testing equipment, it achieves 1200 pieces per hour with a yield rate of 99.2%. This solution won the International Consumer Electronics Association Innovation Technology Award.

Future Outlook: Innovation Driven by Intelligence and Customization

With the development of Industry 4.0 and smart manufacturing, airtightness testing fixtures are evolving toward intelligence and flexibility. WAFU Brothers will continue investing in R&D, planning to launch next-generation fixtures integrated with AI vision recognition and self-diagnostic functions, enabling automatic workpiece identification, intelligent parameter matching, and fault warning. Meanwhile, customized services will deepen, providing full-cycle support from design to mass production for emerging fields such as new energy and aerospace, continuously leading the innovation in airtightness testing fixture technology.

WAFU

WAFU