A Tiny Leak Causing Massive Rework of Automotive A/C Components?

I. Product Overview

Automotive air conditioning components are essential parts of the vehicle A/C system, mainly used for refrigerant delivery, control, and heat exchange. Common components include piping assemblies, connectors, valve bodies, and housings. During vehicle operation, these components must withstand long-term pressure fluctuations, temperature changes, and vibration, placing high demands on material performance, structural strength, and manufacturing processes.

II. Why Do Automotive A/C Components Require Leak Testing?

Automotive A/C components are exposed to long-term refrigerant pressure variations, thermal cycling, and vehicle vibration during operation, requiring extremely high sealing performance and structural stability. Once even a minor leak occurs, it can affect cooling efficiency and may even lead to system failure or safety hazards. Therefore, implementing strict leak testing during production has become a critical step to ensure product quality compliance.

| Ensure Cooling Performance | Automotive A/C systems rely on a sealed refrigerant circuit. Once a component has even a slight leak, refrigerant will gradually escape, directly leading to reduced cooling performance or even complete failure. |

| Ensure Driving Safety | Automotive A/C systems operate under positive or high pressure. Poor sealing may cause pressure instability, and in severe cases, lead to component damage or safety hazards. Leak testing effectively reduces potential risks caused by leakage. |

| Adapt to Harsh Operating Conditions | In real-world use, automotive A/C components undergo high/low temperature cycles, vibration, and aging. Minor sealing defects at an early stage are often amplified over long-term use. Leak testing helps eliminate products with insufficient sealing reliability in advance, improving overall vehicle durability. |

| Safety Requirements | Once leakage occurs in automotive A/C components, safety risks may arise. Some new environmentally friendly refrigerants have low flammability, and leakage in the presence of an open flame may cause danger. |

Figure 1: Conceptual Diagram of Automotive A/C Components

Figure 1: Conceptual Diagram of Automotive A/C Components

III. Basic Solution Concept

The automotive A/C component tested in this case is an aluminum alloy die-cast part. Due to process characteristics, invisible defects such as porosity and cracks may occur after molding. The test area focuses on the main body of the product. After understanding the customer’s daily production volume, a dual-channel, dual-station testing design was adopted to ensure the test cycle meets production efficiency requirements.

Testing Challenge: As a key connecting component, the automotive A/C part features multiple interfaces of different types and sizes.

Solution: Different sealing plugs were designed specifically for each interface.

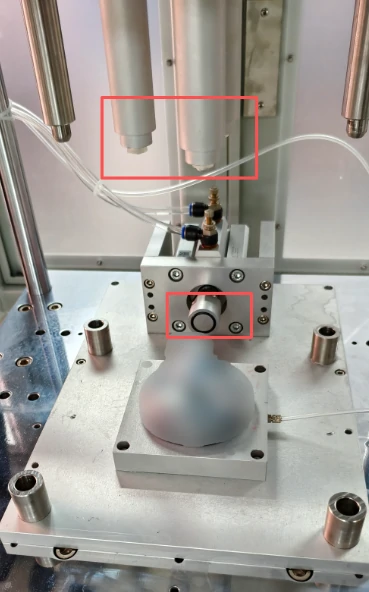

Figure 2: Fixture Used for Product Sealing

Figure 2: Fixture Used for Product Sealing

IV. Final Equipment

Due to the customer’s high test pressure requirements, standard benchtop leak testers could not meet the testing needs. Therefore, we adopted a customized cabinet-type leak tester to satisfy the high-pressure testing requirements.

Figure 3: WAFU Brothers Customized Cabinet-Type Leak Tester

Figure 3: WAFU Brothers Customized Cabinet-Type Leak Tester

V. Testing Procedure

The positive pressure method is adopted, with a test pressure of 2000 kPa and a leakage limit of ±0.05 kPa.

- 1. Place the product to be tested correctly into the designated test station of the fixture.

- 2. Pressing the start button on the left side of the screen, the start button on the control panel, or the on-screen virtual start button will all initiate the test program. The physical button on the left controls all channels, while the control panel button and on-screen button control their respective channels.

- 3. The fixture clamps synchronously press into position to seal the product effectively and begin filling the product with test gas.

- 4. The system automatically executes the complete test procedure, including filling, stabilization, testing, and exhaust stages.

- 5. After testing, the device screen displays the result: PASS for qualified products and FAIL for unqualified ones. Indicator lights synchronize with the test result, and a buzzer alarm can be enabled for failed products.

WAFU

WAFU