Choose the Right Leak Testing Solution to Significantly Improve Yield of Automotive Side Mirror Turn Signals

1. Product Overview

Automotive side mirror turn signals are integrated into the exterior rearview mirrors and are used to provide clear directional indications to surrounding traffic participants during turning or lane changes. These lamps typically use LED light sources, offering fast response, high brightness, and long service life. Modern designs seamlessly integrate the turn signal with the streamlined mirror housing, balancing aerodynamics and visual aesthetics, making it an indispensable component of automotive safety and exterior design.

2. Why Do Automotive Side Mirror Turn Signals Require Leak Testing?

Due to long-term exposure to rain, dust, extreme temperatures, and car washing environments, to ensure reliable operation of automotive side mirror turn signals under various conditions , the product structure must have excellent sealing performance and therefore must undergo rigorous leak testing (waterproof and dustproof testing).

| Prevent Internal Fogging and Water Ingress | If moisture enters the turn signal, it may condense on the inner surface of the lens under temperature changes. Long-term water accumulation can lead to circuit short circuits, LED corrosion, and driver failure, resulting in functional malfunction. |

| Maintain Stable Optical Performance | Moisture or dust adhering to reflectors or LED lenses can cause light scattering and reduced brightness, severely affecting signal visibility and creating potential safety risks. |

| Harsh Operating Environment | Automotive side mirror turn signals are installed on the exterior of the vehicle and are exposed to high-pressure car washing, heavy rain, and day-night temperature variations. Poor sealing allows moisture and contaminants to easily penetrate through housing joints, leading to internal dampness. |

| Meet Industry Quality Standards | Vehicles must meet strict quality standards before leaving the factory, including water and dust protection ratings. As an automotive component, side mirror turn signals must also show compliance with these requirements. |

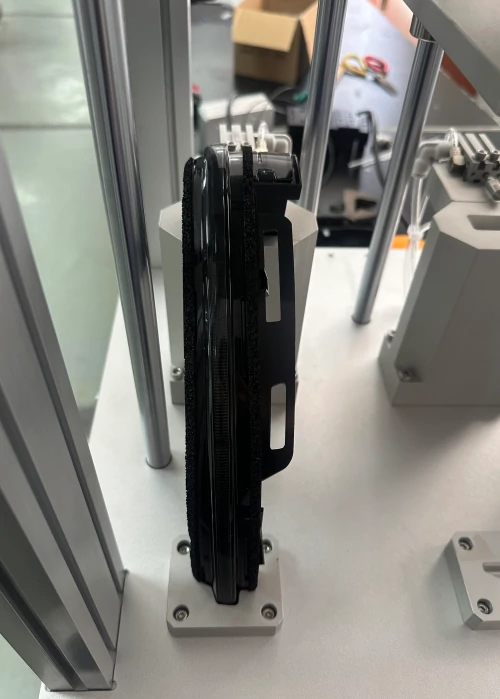

Figure 1: Automotive side mirror turn signal test sample

Figure 1: Automotive side mirror turn signal test sample

3. Basic Solution Concept

Due to the stringent sealing requirements of automotive side mirror turn signals, leak testing must be performed on the entire product.

Testing Challenge: The irregular shape of the side mirror turn signal makes it difficult to design a fully conformal enclosure fixture.

Solution: Except for a single wiring port, the side mirror turn signal is fully sealed when qualified. Therefore, a fully enclosed fixture is unnecessary; test pressure can be applied directly through the wiring port.

Figure 2: Side mirror turn signal positioned on the fixture

Figure 2: Side mirror turn signal positioned on the fixture

Solution Optimization: The original lower fixture design was a fully enclosed structure, which was not conducive to rapid loading. It was redesigned as an open structure to enable quick product loading and unloading . PTFE (Teflon) material was applied at the contact areas to prevent product damage during fixture clamping .

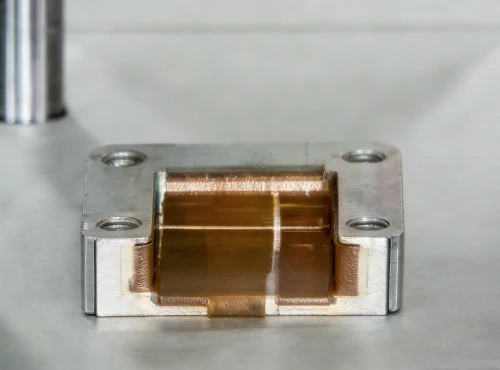

Figure 3: Optimized lower fixture

Figure 3: Optimized lower fixture

4. Final Product

Based on the customer’s production line requirements, a four-station, four-channel side mirror turn signal leak testing machine was designed, enabling simultaneous multi-station testing to meet the customer’s continuous and high-efficiency inspection demands.

Figure 4: WAFU Brothers side mirror turn signal leak testing machine

Figure 4: WAFU Brothers side mirror turn signal leak testing machine

5. Testing Process

The positive pressure method is applied for testing. The test pressure is 150 kPa, and the maximum allowable leakage is 100 Pa.

- 1. Place the product to be tested correctly into the designated test station of the fixture.

- 2. Press both start buttons simultaneously or press the start button below the device to initiate the test program.

- 3. The fixture clamps downward synchronously to ensure airtight sealing at the interface and begins pressurizing the product.

- 4. The system automatically executes the complete test cycle, including pressurization, stabilization, testing, and exhaust.

- 5. After testing, the screen displays the result: PASS for qualified products and FAIL for unqualified ones. The fixture indicator lights synchronize with the test result, and a buzzer alarm can be activated for failed products.

WAFU

WAFU