The Truth Behind Seal Failure in Die-Cast Mold Components—We Found It

I. Product Overview

Die-cast mold components refer to metal parts manufactured using die-casting processes and subsequently used as molds or core mold components in downstream production. Common materials include aluminum alloys, zinc alloys, and magnesium alloys. These components integrate both structural and forming functions, meeting the strength, stability, and precision requirements necessary for mold applications.

II. Why Do Die-Cast Mold Components Require Leak Testing?

Due to the complex metal flow during die casting, internal defects such as porosity, shrinkage cavities, sand holes, and micro-cracks are prone to occur. These issues are often difficult to detect through visual inspection, yet they directly affect sealing performance. Therefore, conducting leak testing and sealing verification on die-cast mold components has become a critical quality control step prior to shipment, effectively ensuring reliable leak prevention, waterproofing, and pressure resistance under real operating conditions.

| Inherent Process-Related Internal Defects | During high-temperature, high-speed filling in die casting, internal defects such as porosity, shrinkage cavities, and micro-cracks are often unavoidable. These hidden defects are difficult to identify through appearance or dimensional inspection, yet they can become leakage paths during actual use. |

| Extremely High Sealing Requirements in Mold Operation | When used as molds, die-cast mold components frequently withstand pressure media and operate long-term under vacuum or alternating positive and negative pressure conditions. Any leakage may result in incomplete product filling. |

| Ensuring Service Life | Some sealing issues do not immediately appear during production and only become evident after extended use, eventually leading to mold scrapping or line stoppages for maintenance. Leak testing identifies potential risks before the mold is put into service, avoiding costly rework and downtime later. |

| Safeguarding Product Forming Accuracy | Once leakage occurs in a die-cast mold component, it directly affects pressure distribution and forming conditions within the mold cavity, resulting in molding defects and significant batch-to-batch quality fluctuations. Leak testing is a vital quality control measure to ensure stable and consistent production output. |

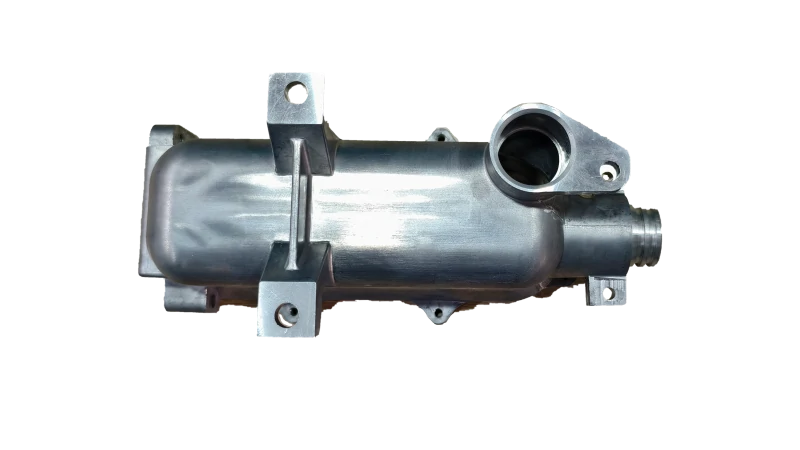

Figure 1: Die-cast mold component sample provided by the customer for testing

Figure 1: Die-cast mold component sample provided by the customer for testing

III. Key Testing Points

The product is a die-cast mold that must ensure overall sealing integrity. However, due to the nature of die casting, invisible gaps and sand holes may form during production. Therefore, the entire component must be tested.

Testing Challenge: The entire product must be tested, but its relatively large volume and deep, wide cavities may increase testing time.

Solution: Customized contour inserts were designed to effectively wrap and fill cavity areas, reducing internal volume and shortening test time.

IV. Final Equipment Solution

Due to the high test pressure required by the customer, conventional benchtop leak testers could not meet the requirements. Therefore, our engineers designed an all-in-one tester with integrated fixtures to support high-pressure leak testing.

Figure 2: All-in-one leak testing machine with integrated fixtures for die-cast mold components, ready for shipment

Figure 2: All-in-one leak testing machine with integrated fixtures for die-cast mold components, ready for shipment

V. Testing Procedure

The test requires IP68 waterproof rating verification. A positive pressure method is used, with a test pressure of 150 kPa and a maximum allowable leak rate of 200 Pa.

- 1. Place the product into the contoured insert inside the fixture.

- 2. Press both start buttons simultaneously, or tap the start button on the screen to initiate the test program.

- 3. The upper fixture automatically descends to seal the product, followed by charging the test gas into the product.

- 4. The test sequence consists of four stages: pressurization, stabilization, measurement, and exhaust.

- 5. Upon completion, the screen displays the result (PASS/FAIL), and the fixture indicator lights illuminate simultaneously. An audible alarm can be triggered for non-conforming products.

WAFU

WAFU