After seeing this case, you’ll never ignore leak testing of air conditioner die-cast parts again!

1. Product Overview

Die-cast parts in air conditioner components are commonly used in key positions such as the refrigeration cycle, structural support, and sealing connections of the AC system. Typical AC die-cast parts include compressor end covers, valve bodies, joints, pipe connectors, heat exchanger fittings, and mounting brackets. These parts are usually manufactured using aluminum alloy die-casting, offering features such as light weight, high strength, excellent corrosion resistance, and superior heat dissipation, which meet the strict requirements for pressure, temperature, and medium resistance during long-term operation of air conditioning systems.

2. Why Perform Leak Testing on AC Die-Cast Parts?

Since AC die-cast parts directly participate in high-pressure refrigerant cycles (e.g., R32, R410A), they require extremely high sealing reliability and structural integrity. If the die-cast parts have porosity, cracks, thin-wall deformation, or sealing surface defects, it may lead to refrigerant leakage, unstable system pressure, reduced energy efficiency, or even safety risks.

| Prevent air or moisture intrusion | Poor sealing may allow air moisture or impurities into the system. Moisture can freeze at low temperatures, blocking pipes, or react with refrigerant to produce acidic substances that corrode internal components. |

| Maintain system pressure | The refrigeration system needs to operate at a specific pressure. Leaks can disrupt the pressure balance, increase compressor load, reduce energy efficiency, and even cause damage due to overheating. |

| Prevent long-term risks | Small leaks may not affect initial use, but over time they worsen, causing premature AC failure. Leak testing helps filter defective parts, improving overall reliability. |

| Protect electrical components | AC units contain circuits and electronic components. If leaks allow moisture to enter, it can cause short circuits or electric leakage. |

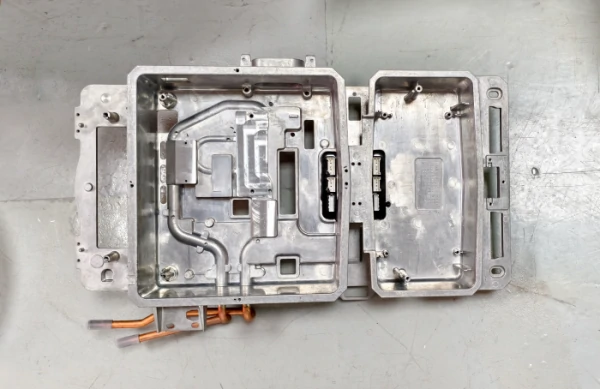

Figure 1: Sample AC die-cast parts for

testing

Figure 1: Sample AC die-cast parts for

testing

3. Key Points of Testing

Due to the characteristics of die-casting, defects such as porosity and cracks that are invisible to the naked eye may appear after production. Leak testing for AC die-cast parts focuses on detecting these potential defects across the entire product.

Challenges: The products to be tested are large in size, with long testing times, and standard desktop fixtures may not accommodate them.

Solution: Internal fillers are used without tightly surrounding the product, reducing the test volume and accelerating inflation and holding time, thus improving overall testing efficiency. The equipment features a custom integrated design, facilitating loading/unloading while saving space.

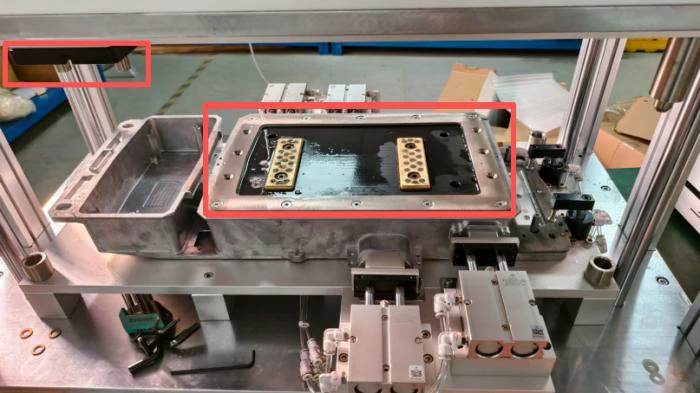

Figure 2: Upper part of the fixture for

product filling

Figure 2: Upper part of the fixture for

product filling

4. Final Product

According to the customer's IP67 waterproof requirements, a custom integrated leak testing device was designed, using positive pressure method for single-channel testing. The device shown is the WaFu Brothers multifunctional leak tester , which can be flexibly customized with various testing methods, offering high testing efficiency and more intelligent system control, suitable for airtightness, sealing, and waterproof testing of products across different industries.

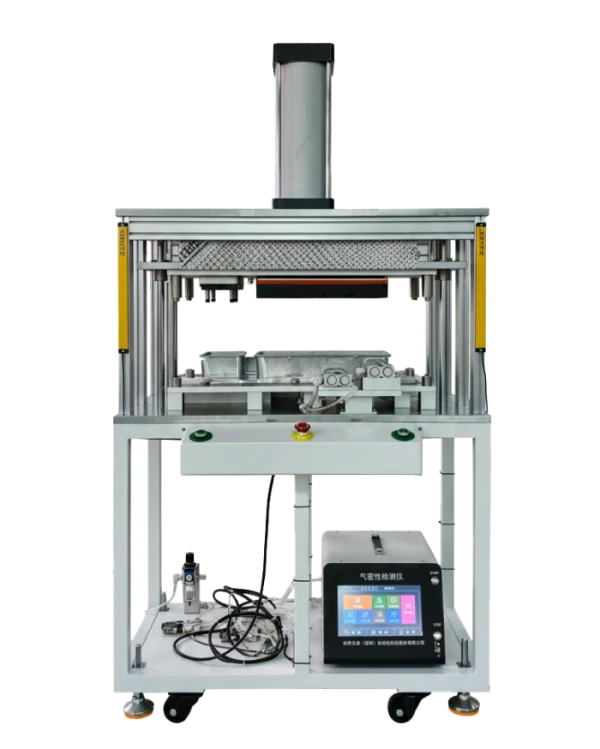

Figure 3: WaFu Brothers custom

integrated leak testing device

Figure 3: WaFu Brothers custom

integrated leak testing device

5. Testing Process

Using the positive pressure method, the test pressure is 15kPa, and the leak limit is 200Pa.

- 1. Place the product in the designated position of the fixture.

- 2. Press the start buttons on both sides to initiate testing.

- 3. Clamp around the product to seal it, then begin inflating the product.

- 4. Start the test, which consists of four stages: inflation, pressure holding, detection, and exhaust.

- 5. After testing, the result is displayed on the screen: PASS for qualified, FAIL for unqualified. Indicator lights on the fixture correspond to the results. For defective products, a buzzer alarm can be set.

WAFU

WAFU