Unstable Waterproof Performance? The Sealing Issues of Portable Electric Cleaning Brushes Are Actually Exposed During Testing

I. Product Overview

The portable electric cleaning brush is a household electronic cleaning device that combines high-efficiency cleaning with convenient operation. It adopts advanced high-frequency vibration/rotation technology and is equipped with various brush head designs, enabling deep cleaning of car interiors, fabrics, and household surfaces. Compact and lightweight, it is easy to carry and store, making it suitable for home use, travel, and a wide range of cleaning scenarios.

Figure 1: Portable electric cleaning brush sample used for testing

Figure 1: Portable electric cleaning brush sample used for testing

II. Why Does a Portable Electric Cleaning Brush Require Leak Testing?

As a cleaning tool, the portable electric cleaning brush is often used in humid environments or in direct contact with water, which places high demands on sealing performance. Through leak testing, it is possible to effectively prevent defective products from entering the market while also ensuring product service life.

| Prevent Water Ingress | The product is used in bathrooms, kitchens, washbasins, and other humid environments, and may even come into direct contact with water. If there are tiny leaks in the housing, buttons, charging port, or assembly seams, moisture or liquid can easily enter the interior, leading to motor or PCB short circuits and potential safety hazards. Leak testing can effectively screen out potential water ingress risks before shipment, ensuring end-user safety. |

| Enhance User Confidence | Portable electric cleaning brushes on the market are usually labeled with a waterproof rating. Leak testing is an essential prerequisite for achieving and verifying this rating, determining whether the product meets its designed waterproof standards. It can replace or reduce full immersion testing, significantly improving test efficiency. |

| Production Quality Control | By implementing leak testing, sealing defects can be detected during the inspection stage, reducing after-sales costs. It also enables incoming inspection of sealing components supplied by vendors, such as silicone gaskets and waterproof membranes, in case of supply chain issues. |

| Adapt to Product Characteristics | Portable electric cleaning brushes typically have multiple potential leak points, such as the connection between the brush head and the main body, housing seams, buttons, sealing rings, and Type-C / USB charging ports. Leak testing enables quantitative inspection of the entire product or critical areas, ensuring that all sealing structures maintain reliable sealing performance after assembly. |

III. Key Testing Considerations

The customer required the instrument to be compatible with different product models, so a fixture capable of testing multiple models was designed.

Figure 2: Fixture compatible with testing different models of portable electric cleaning brushes

Figure 2: Fixture compatible with testing different models of portable electric cleaning brushes

Testing Challenge: The products under test are finished goods, so the fixture must clamp securely without damaging the product surface.

Solution: PTFE (Teflon) was applied to the contact surfaces between the fixture and the product to reduce friction and prevent surface damage during clamping.

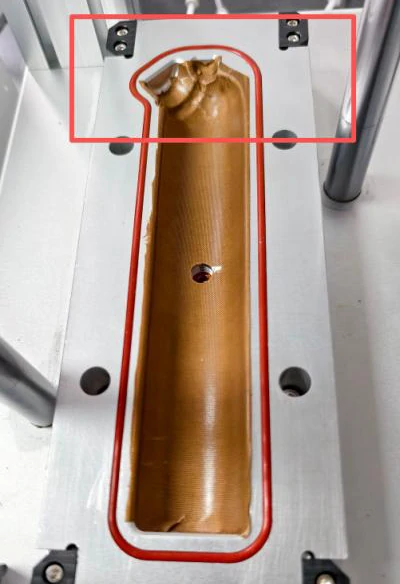

Figure 3: PTFE applied to the fixture contact surface

Figure 3: PTFE applied to the fixture contact surface

IV. Final Solution

Based on the customer’s product characteristics, testing requirements, and daily production volume, a four-channel leak testing system with customized fixtures was designed. The instrument used in the solution is the WAFU Brothers Multifunctional Leak Tester , which supports flexible customization of multiple test methods and multi-channel configurations, making it suitable for airtightness, sealing, and waterproof performance testing across various industries.

Figure 4: Four-channel leak tester for portable electric cleaning brushes

Figure 4: Four-channel leak tester for portable electric cleaning brushes

V. Testing Procedure

The test requires compliance with the IP68 waterproof rating. A positive pressure method is applied, with a test pressure of 20 kPa and a maximum allowable leakage of 100 Pa.

- 1. Place the product in the designated area of the fixture.

- 2. Press the start buttons on both sides simultaneously or tap the start button on the screen to activate the test program.

- 3. The upper fixture automatically presses down to seal the product, then test gas is injected into the product.

- 4. The testing process consists of four stages: pressurization, stabilization, testing, and exhaust.

- 5. After completion, the screen displays the result (PASS/FAIL), and the indicator lights on the fixture synchronize accordingly. A buzzer alarm can be enabled for failed products.

WAFU

WAFU