Can a Small Water Tank Ruin an Entire Robot Vacuum? This Leak Test Explains Why!

I. Product Overview

As an important product in the smart home sector, robot vacuum cleaners have evolved rapidly with increasing user expectations for cleaning performance and user experience. They have developed from simple dry-cleaning devices into comprehensive cleaning systems featuring automatic mopping, intelligent water control, and precise water output. Under these requirements, the robot vacuum water tank has become one of the core components enabling wet-mopping functionality. The water tank is mainly used to store cleaning water and deliver it evenly to the mop through internal water channels, valves, or pumps, ensuring consistent and effective mopping performance.

II. Why Does a Robot Vacuum Water Tank Need Leak Testing?

During operation, the water tank remains filled with water for long periods and is subject to repeated installation, removal, vibration, and environmental temperature changes. If there are sealing defects or microscopic cracks, water seepage or leakage is very likely to occur.

| Protect Internal Electronic Components | Robot vacuum cleaners integrate numerous precision electronic components. If water leakage occurs due to poor sealing of the water tank, moisture can damage internal circuits, motors, or the main control system. |

| Ensure Stable Water Control | Insufficient sealing of the water tank may result in unstable water pressure, uneven water output, or failure of water control, directly affecting mopping performance. Leak testing ensures the tank remains stable under specified pressure conditions. |

| Identify Manufacturing Defects | During plastic injection molding, microscopic pores or cracks may form inside the water tank, which are difficult to detect through visual inspection. Leak testing can accurately identify defective products in a short time, improving outgoing product quality. |

| Avoid Secondary Contamination | Water leakage may cause dirty water to seep into the dust box or roller brush, leading to bacterial growth and unpleasant odors, and increasing the user’s cleaning and maintenance burden. |

Figure 1: Robot vacuum water tank sample under testing

Figure 1: Robot vacuum water tank sample under testing

III. Key Testing Points

The robot vacuum water tank tested in this case is a plastic component. During the molding process, plastic parts may develop microscopic pores that are invisible to the naked eye, making it necessary to perform a comprehensive leak test on the entire product.

Testing Challenge: The robot vacuum water tank needs to connect to multiple pipelines, resulting in many holes of different sizes, which significantly increases the difficulty of sealing.

Solution: Side-push sealing fixtures were designed for areas with openings, using custom-made sealing rings. Different specifications were applied to different hole sizes, ensuring that each opening could be effectively sealed.

Figure 2: WaFu Brothers technicians making custom sealing rings

Figure 2: WaFu Brothers technicians making custom sealing rings

IV. Final Solution

Based on the customer’s daily production volume and requirements, a single-channel leak tester with a dedicated fixture was designed. The connected testing instrument is the WaFu Brothers Multifunction Leak Tester , which supports flexible multi-channel customization and offers high sensitivity and superior accuracy. It is suitable for sealing, waterproof, and leak testing applications across various industries.

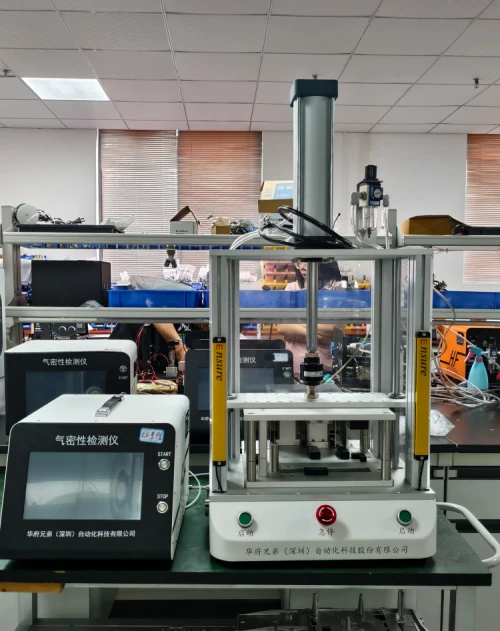

Figure 3: Leak tester and fixture for robot vacuum water tanks

Figure 3: Leak tester and fixture for robot vacuum water tanks

V. Testing Process

This case adopts the positive pressure method, with a test pressure of 15 kPa and a maximum allowable leakage of 150 Pa.

- 1. Place the product to be tested correctly into the designated position of the fixture.

- 2. Press the start buttons on both sides of the device simultaneously to initiate the automatic testing sequence.

- 3. The fixture clamps press inward from all sides to seal the product, and internal pressurization begins.

- 4. The device executes the preset testing program in sequence, including four stages: pressurization, pressure stabilization, leak detection, and exhaust.

- 5. After the test is completed, the screen displays the final result: PASS for qualified products and FAIL for unqualified ones. Indicator lights on the fixture synchronize with the test result. For failed products, an audible buzzer alarm can be activated.

WAFU

WAFU