Overcoming Thermal and Noise Barriers for Smart Non-Destructive Testing: WAFU Brothers Redefine Airtightness Detection Standards

In the process of industrial manufacturing moving toward high-end and intelligent development, airtightness testing has become a core technology for ensuring product quality, widely applied in key sectors such as automobile manufacturing, aerospace components, and medical devices. With continuous improvements in machining precision, high-precision airtightness testing equipment has an increasingly direct impact on product performance and safety. However, the accuracy of an airtightness tester is often constrained by multiple factors — including sensor performance, testing methods, ambient temperature, and noise interference.

Extensive on-site verification has shown that fluctuations in ambient temperature and noise interference are the two most significant challenges. With 16 years of deep expertise in the airtightness testing industry, WAFU Brothers has leveraged cutting-edge technological innovations to achieve breakthroughs in temperature resistance, noise suppression, non-destructive testing, and intelligent calibration. These advancements have brought revolutionary changes to the airtightness testing field, redefining industry standards!

1. Environmental Factors Affecting Testing Accuracy

Impact of Ambient Temperature Changes on Testing Accuracy

1. According to the ideal gas law PV = nRT, when volume and pressure remain constant, changes in temperature will alter the density of gas molecules, directly changing the physical properties of the tested gas and thereby affecting the measurement value.

2. When the temperature rises, gas molecules move faster and pressure increases; when the temperature drops, the opposite occurs. Such variations in molecular motion can also be misinterpreted as leakage.

3. The flow characteristics of gases change with temperature, causing deviations in the readings of flow meters or sensors.

In addition, variations in ambient temperature can also have minor effects on sensors, mechanical components, and electronic circuits. Even a seemingly small change of 1–2°C can lead to deviations of several pascals in extremely high-precision testers. For example, during the inspection of a hot water tank body, gas needs to be filled into a large-capacity container, and deviations are almost inevitable even with temperature control devices in place.

2. Impact of Noise on Testing Accuracy

The most common issues include the following:

| Type of Interference | Typical Source | Transmission Path | Affected Indicator | Control Measures |

|---|---|---|---|---|

| Pneumatic Pressure Pulsation | Piston-type compressors, diaphragm pumps | Pneumatic system → Test chamber | Test pressure fluctuation, leakage rate calculation error | Install surge tanks, pneumatic dampers; use pulsation-free air source |

| Low-Frequency Mechanical Vibration | Punch presses, welding machines, handling robots | Floor/frame → Sensor sensitive element | Pressure/flow signal jitter, false leakage signals | Vibration isolation base, remote placement of testing equipment |

| Electromagnetic Interference (EMI) | Variable frequency drives, large motors, welding machines | Cable induction/radiation → Signal acquisition circuit | Analog signal offset, reduced A/D conversion accuracy | Signal line shielding, filters, equipment grounding and isolation |

| Transient Pneumatic Shock | Rapid switching of solenoid valves, multi-channel pneumatic switching | Valve outlet → Test chamber | Pressure spike, abnormal data points | Soft-start valves, buffer air chambers, optimized pneumatic layout |

| Power Supply Ripple & Noise | Switching power supplies, power system fluctuations | Power input → Control and measurement module | Zero drift, unstable signals | Linear voltage regulation, low-ripple power supply, independent power supply |

3. Solutions to Key Challenges in the Airtightness Tester Industry

Methods to Address Ambient Temperature Issues

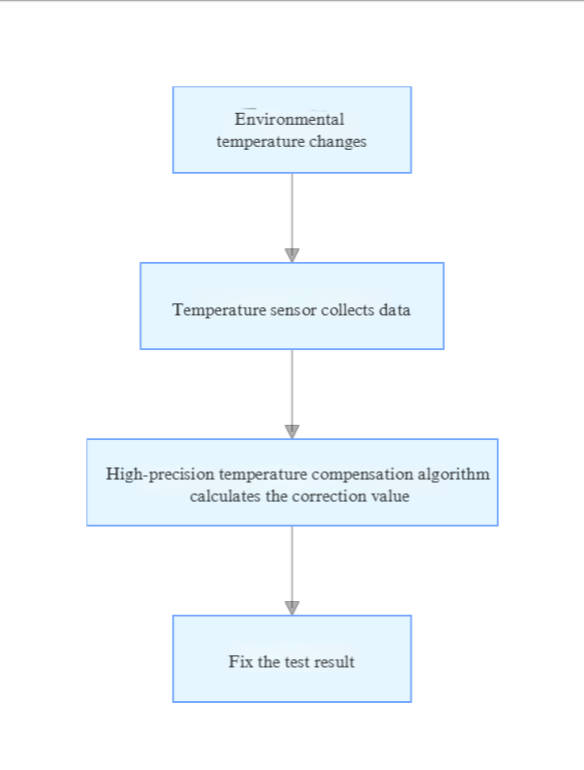

1. Temperature Compensation (Equip the instrument with a “temperature sensor” to monitor ambient temperature in real time, then use algorithms to automatically adjust the measurement data for higher accuracy.)

2. Constant Temperature Control (Install a “mini air conditioner” in the testing environment to keep the temperature stable) — like putting a thermal jacket on the instrument to protect it from hot and cold fluctuations.

3. Temperature Isolation (Use thermal insulation materials to block external temperature changes) — like keeping a drink in a thermos to maintain heat or cold.

4. Calibration and Verification (Regularly check the instrument’s performance under different temperatures) — similar to periodically calibrating a thermometer to ensure accurate readings.

Figure 2. WAFU Brothers Temperature Compensation Technology Principle Diagram

Methods to Address Noise Issues

1. On the hardware side, design high anti-interference sensors and signal transmission lines, and apply shielding and filtering technologies to reduce interference.

2. On the software side, develop advanced signal processing algorithms to intelligently filter out noise signals and extract true and valid data.

4. Application Results

By applying innovative technologies to airtightness testers, WAFU Brothers engineers, through extensive repeated testing and continuous upgrades and improvements, have achieved more than a 70% increase in airtightness testing accuracy, a 25% improvement in efficiency, and raised the product pass rate to 99.8%, effectively ensuring product quality.

5. Conclusion

WAFU Brothers’ technological breakthroughs have set a new benchmark for the airtightness testing industry. In the future, WAFU Brothers will continue to focus on the field, optimizing existing technologies and expanding applications in areas such as new energy vehicle battery packs and aerospace precision components, driving airtightness testing technology to a higher level. For more product and technical information, please contact: +86 17376311087.

WAFU

WAFU