Just One Step Away — Your Robot Vacuum Plastic Connector May Completely Fail Leak Testing!

1. Product Overview

With fierce competition across the home appliance industry, robot vacuums now cover a wide range of price levels and have become essential household cleaning devices. A robot vacuum relies heavily on its internal systems—including air and water pipelines—to operate properly. Among them, the plastic connector plays a crucial role in linking various pipelines. It is commonly used in air ducts, suction paths, water tank outlets, and mop water-supply channels, ensuring smooth transmission of air or liquid.

2. Why Do Robot Vacuum Plastic Connectors Require Leak Testing?

Robot vacuums experience frequent vibration and internal pressure fluctuations during operation. Therefore, plastic connectors must not only offer enough mechanical strength but also maintain reliable sealing performance to prevent air or water leakage that may affect suction or mopping efficiency. This makes leak testing a critical part of robot vacuum quality assurance.

| Suction decreases, cleaning becomes ineffective | If the plastic connector leaks, the air pressure inside the duct drops, causing major suction loss. This results in poor debris pickup, hair remaining on the floor, and visibly reduced cleaning performance. |

| Increased machine noise | Air leakage disrupts airflow stability, increases duct vibration, and causes sharp or abnormal noise, negatively affecting user experience. |

| Unstable mop water supply | Poor sealing in water-line connectors may cause water leakage from the machine base, potentially damaging electronic components. |

| Quality control must be reliable | Plastic connectors are small and structurally complex. Factors such as molding tolerance and ultrasonic-welding variations affect sealing performance. Therefore, leak testing is essential to ensure each connector meets sealing standards before shipment. |

Figure 1: Robot vacuum plastic connector used for testing

Figure 1: Robot vacuum plastic connector used for testing

3. Solution Design

The robot vacuum plastic connector is welded using ultrasonic welding. Therefore, the main testing focus is on the upper and lower ultrasonic weld areas to check for leaks. This means the leak testing of this plastic connector is essentially ultrasonic-weld leak testing, targeting weld seams.

Testing Challenge: The connector is small with limited internal volume, and micro-leaks are difficult to magnify. This requires extremely high sensitivity from the leak tester.

Solution: Use customized high-precision sensors to capture subtle pressure changes.

Wafu Brothers’ sensors are custom-made by top-tier industry manufacturers. Different specifications are tailored based on product testing requirements, ensuring reliable and industry-leading precision.

4. Final Product

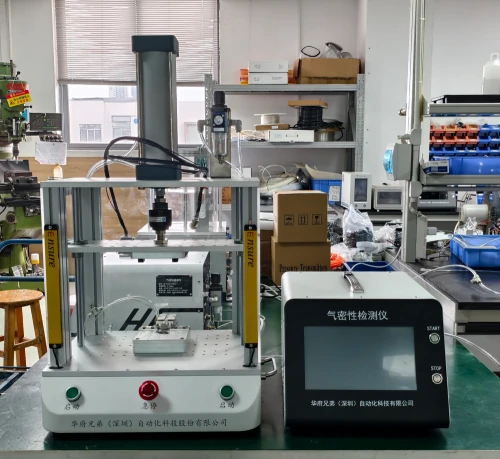

Based on customer requirements, the leak tester uses the Positive Pressure Method for single-channel testing. The fixture shown in the image is paired with the Wafu Brothers Multifunctional Leak Tester , which supports customization of various test methods. The testing process is efficient, and the built-in system is more intelligent, suitable for leak, sealing, and waterproof testing across multiple industries.

Figure 4: Final leak tester and customized fixture

Figure 4: Final leak tester and customized fixture

6. Testing Process Demonstration Video

The testing parameters are: 30 KPa pressure and 10 seconds testing time. The maximum allowable leakage threshold provided by the customer is 50 Pa. The video below demonstrates the full testing process:

7. Conclusion

This robot vacuum plastic float leak testing project and the Robot Vacuum Plastic Float Leak Testing Project were both commissioned by the same customer. We sincerely appreciate their trust, which has allowed Wafu Brothers to further expand its capabilities in robot vacuum leak testing technology. Wafu Brothers will continue enhancing equipment intelligence and delivering faster, more accurate, and smarter leak testing solutions for more industries.

WAFU

WAFU